- Panasonic Ram Dash Linear Men's Shaver 6 Blades Craft Black ES-CLS9AX-KRam DASH and LINEAR shavings for fast shavings, deepest shavings, and skin that is easy on the skin Please be sure to take a look at the product's more than a minute's reading and what to look out for before you make a product! To request a return or exchange, please note that it is mandatory to provide a video of the unpacking of the package.

- TonePros GKS60K B Tuner Black Black"TonePros GKS60K B Tuner Black, Machine Heads for Electric Guitar, Locking machine heads, Sealed construction, Configuration: 6-in-line, bass side (left), Gear ratio: 18:1, Shaft diameter: 6 mm, Mounting diameter: 10 mm, ""Kidney"" style buttons, Colour: Black"

- TonePros GKL60K-B Locking Tuner BL Black"TonePros GKL60K-B Locking Tuner BL, Machine Heads for Electric Guitar, Locking machine heads, Sealed design, Configuration: 6-in-line, bass side (left), Gear ratio: 18:1, Shaft diameter: 6 mm, Installation diameter: 10 mm, ""Small Kidney"" style buttons, Colour: Black"

- Moover : Moteur pour abri de piscine jusqu'a abri - CMoover : Le moteur pour abri piscine ! Vous avez investi dans un abri de piscine mais quand il s’agit de profiter de votre piscine, il vous faut l’ouvrir et le refermer une fois la baignade terminée. Si vous êtes à la recherche d’une solution pour motoriser votre abri de piscine, alors vous êtes au bon endroit. Grâce à la conception unique, vous pouvez installer le MOOVER sur des abris neufs ou existants de la société ALBIXON ainsi que d’autres marques. Il n'est pas possible d'installer le Moover sur : les abri sans rails, Avec angle négatifou plus lourd que 750 kilos - Moteur pour abri de piscine MOOVER - ALBIXON Un design élégant et une autonomie remarquabl Le design du Moover est pensé pour s’intégrer facilement dans vos extérieurs. Il est discret et prend très peu de place afin de préserver l’espace autour du bassin. De plus, Moover est doté de panneaux solaires qui lui permettent de fonctionner durant toute la saison estivale soit 3 mois. Grâce à sa batterie haute capacité dernière technologie, il peut fonctionner 1,5 heures en continu et jusqu’à 800 heures en mode veille. Une révolution dans l’utilisation de votre abri de piscine Développé en collaboration avec des ingénieurs de l’automobile, Moover vous permet de faire bouger votre abri de piscine sans effort . Son secret réside dans sa roue motorisée située à l’intérieur du boîtier. Il vous suffit d’appuyer sur un bouton pour ensuite piquer une tête, Moover vous fait gagner du temps et économiser vos efforts. Et quand vous ne souhaitez pas activer l'assistance de Moover, il vous suffit de dévisser l’écrou papillon afin de relâcher la pression de la roue. Grâce à la télécommande avec une portée de 30 mètres, vous pouvez facilement contrôler l’ouverture et la fermeture de votre abri de piscine. Et elle est si simple d’utilisation que tous les membres de la famille peuvent l’utiliser. Motoriser votre abri de piscine devient un jeu d’enfant : Moover est livré avec une notice de montage très bien détaillée qui vous permet de monter facilement le système d’ouverture et de fermeture de l’abri de piscine. Vous pouvez le faire seul, cela ne vous prendra que quelques heures. Et n’oubliez pas que les experts de Distripool sont à votre disposition pour vous aider à installer votre Moover. Moover s'adapte sur tous les abris de piscine dont le pas des arcs est de 1063 mm et le plan latéral ne présente pas d'angle d'incidence négatif. . Fiche technique : Moteur MOOVER pour abri de piscine Photo du MOOVER ALBIXON

- Moover : Moteur pour abri de piscine jusqu'a abri - CMoover : Le moteur pour abri piscine ! Vous avez investi dans un abri de piscine mais quand il s’agit de profiter de votre piscine, il vous faut l’ouvrir et le refermer une fois la baignade terminée. Si vous êtes à la recherche d’une solution pour motoriser votre abri de piscine, alors vous êtes au

- Robot de piscine Bestway Ruby Tri-moteursRobot piscine Bestway Ruby Tri-moteurs - Technologie sans fil Nettoyage optimisé du fond et des parois jusqu’à la ligne d’eau Ruby est un petit joyau dans l’univers des robots électriques pour piscines : il allie les avantages de la technologie sans fil à l’aisance de déplacement des robots électriques équipés de 3 moteurs. Fini les càbles emmêlés ou trop courts pour aller nettoyer correctement les angles de la piscine, le robot Bestway Ruby a toute la liberté nécessaire pour se déplacer partout à l’intérieur de votre piscine et il a la puissance nécessaire pour remonter les parois pour y aspirer les saletés qui s’y déposent. La puissance de ses 3 moteurs lui permet de se déplacer et monter aux parois sans affaiblir la puissance d’aspiration et donc conserver une qualité de filtration constante au cours de son cycle de nettoyage de 90 minutes. La batterie qui équipe le robot Ruby lui permet d’avoir la puissance nécessaire pour effectuer un nettoyage d’entretien complet en 90 minutes, elle pourra être rechargée en 7 à 8 heures une fois le robot sec et connecté à une source d’alimentation. Son poids plume lui permet d’être mis à l’eau et ressorti très facilement sans effort conséquent pour que le nettoyage de la piscine ne soit plus une contrainte. Le capteur d’eau qu’il embarque lui permet de démarrer automatiquement lorsque vous le plongez dans l’eau et commencer ainsi son travail de nettoyage. Les cassettes filtrantes qui équipent ce modèle Ruby ont une capacité importante pour lui permettre d’aller au bout de son cycle de nettoyage sans arrêt prématuré pour motif de filtre plein, et elles ont une capacité de filtration de 180 microns qui est particulièrement adaptée aux piscines où l’on retrouves des débris végétaux, morceaux de feuilles, terre, etc... Ruby détectera automatiquement sa sortie de l’eau gràce à ce même capteur et se coupera donc pour préserver totalement son moteur. Qualité de conception et de fabrication Bestway Gràce à son savoir-faire, Bestway propose aujourd’hui le modèle Ruby, un robot autonome qui vous libère des contraintes des càbles et permet un nettoyage efficace du fond à la ligne d’eau, adapté à tout type de piscine. La batterie Lithium-ion permet de conserver des performances constantes tout au long du cycle de nettoyage. C’est un élément technique important trop souvent négligé et qui sera pourtant déterminant pour une durée de vie optimale. Ruby n’est retenu par aucun càble, cela lui permet d’avoir une amplitude maximale pour ses déplacements. Plus petit et plus léger qu’un robot électrique classique, il sera plus facile à manipuler et vous facilitera grandement l’entretien de votre piscine. Pour quelles piscines ? Tout type de piscines hors-sol ou enterrées jusqu’à 8 x 4m Tout type de formes Fond plat et pentes composées jusqu’à 30° Tout revêtement (liner, carrelage, béton peint, coque, etc...) Informations complémentaires Batterie rechargeable : Lithium-ion 8800 mAh Autonomie de la batterie : 1h30 (soit 90...

- Moover : Moteur pour abri de piscine jusqu'a abri - AMoover : Le moteur pour abri piscine ! Vous avez investi dans un abri de piscine mais quand il s’agit de profiter de votre piscine, il vous faut l’ouvrir et le refermer une fois la baignade terminée. Si vous êtes à la recherche d’une solution pour motoriser votre abri de piscine, alors vous êtes au bon endroit. Grâce à la conception unique, vous pouvez installer le MOOVER sur des abris neufs ou existants de la société ALBIXON ainsi que d’autres marques. Il n'est pas possible d'installer le Moover sur : les abri sans rails, Avec angle négatifou plus lourd que 750 kilos - Moteur pour abri de piscine MOOVER - ALBIXON Un design élégant et une autonomie remarquabl Le design du Moover est pensé pour s’intégrer facilement dans vos extérieurs. Il est discret et prend très peu de place afin de préserver l’espace autour du bassin. De plus, Moover est doté de panneaux solaires qui lui permettent de fonctionner durant toute la saison estivale soit 3 mois. Grâce à sa batterie haute capacité dernière technologie, il peut fonctionner 1,5 heures en continu et jusqu’à 800 heures en mode veille. Une révolution dans l’utilisation de votre abri de piscine Développé en collaboration avec des ingénieurs de l’automobile, Moover vous permet de faire bouger votre abri de piscine sans effort . Son secret réside dans sa roue motorisée située à l’intérieur du boîtier. Il vous suffit d’appuyer sur un bouton pour ensuite piquer une tête, Moover vous fait gagner du temps et économiser vos efforts. Et quand vous ne souhaitez pas activer l'assistance de Moover, il vous suffit de dévisser l’écrou papillon afin de relâcher la pression de la roue. Grâce à la télécommande avec une portée de 30 mètres, vous pouvez facilement contrôler l’ouverture et la fermeture de votre abri de piscine. Et elle est si simple d’utilisation que tous les membres de la famille peuvent l’utiliser. Motoriser votre abri de piscine devient un jeu d’enfant : Moover est livré avec une notice de montage très bien détaillée qui vous permet de monter facilement le système d’ouverture et de fermeture de l’abri de piscine. Vous pouvez le faire seul, cela ne vous prendra que quelques heures. Et n’oubliez pas que les experts de Distripool sont à votre disposition pour vous aider à installer votre Moover. Moover s'adapte sur tous les abris de piscine dont le pas des arcs est de 1063 mm et le plan latéral ne présente pas d'angle d'incidence négatif. . Fiche technique : Moteur MOOVER pour abri de piscine Photo du MOOVER ALBIXON

- Moover : Moteur pour abri de piscine jusqu'a abri - BMoover : Le moteur pour abri piscine ! Vous avez investi dans un abri de piscine mais quand il s’agit de profiter de votre piscine, il vous faut l’ouvrir et le refermer une fois la baignade terminée. Si vous êtes à la recherche d’une solution pour motoriser votre abri de piscine, alors vous êtes au bon endroit. Grâce à la conception unique, vous pouvez installer le MOOVER sur des abris neufs ou existants de la société ALBIXON ainsi que d’autres marques. Il n'est pas possible d'installer le Moover sur : les abri sans rails, Avec angle négatifou plus lourd que 750 kilos - Moteur pour abri de piscine MOOVER - ALBIXON Un design élégant et une autonomie remarquabl Le design du Moover est pensé pour s’intégrer facilement dans vos extérieurs. Il est discret et prend très peu de place afin de préserver l’espace autour du bassin. De plus, Moover est doté de panneaux solaires qui lui permettent de fonctionner durant toute la saison estivale soit 3 mois. Grâce à sa batterie haute capacité dernière technologie, il peut fonctionner 1,5 heures en continu et jusqu’à 800 heures en mode veille. Une révolution dans l’utilisation de votre abri de piscine Développé en collaboration avec des ingénieurs de l’automobile, Moover vous permet de faire bouger votre abri de piscine sans effort . Son secret réside dans sa roue motorisée située à l’intérieur du boîtier. Il vous suffit d’appuyer sur un bouton pour ensuite piquer une tête, Moover vous fait gagner du temps et économiser vos efforts. Et quand vous ne souhaitez pas activer l'assistance de Moover, il vous suffit de dévisser l’écrou papillon afin de relâcher la pression de la roue. Grâce à la télécommande avec une portée de 30 mètres, vous pouvez facilement contrôler l’ouverture et la fermeture de votre abri de piscine. Et elle est si simple d’utilisation que tous les membres de la famille peuvent l’utiliser. Motoriser votre abri de piscine devient un jeu d’enfant : Moover est livré avec une notice de montage très bien détaillée qui vous permet de monter facilement le système d’ouverture et de fermeture de l’abri de piscine. Vous pouvez le faire seul, cela ne vous prendra que quelques heures. Et n’oubliez pas que les experts de Distripool sont à votre disposition pour vous aider à installer votre Moover. Moover s'adapte sur tous les abris de piscine dont le pas des arcs est de 1063 mm et le plan latéral ne présente pas d'angle d'incidence négatif. . Fiche technique : Moteur MOOVER pour abri de piscine Photo du MOOVER ALBIXON

- Moover : Moteur pour abri de piscine jusqu'a abri - AMoover : Le moteur pour abri piscine ! Vous avez investi dans un abri de piscine mais quand il s’agit de profiter de votre piscine, il vous faut l’ouvrir et le refermer une fois la baignade terminée. Si vous êtes à la recherche d’une solution pour motoriser votre abri de piscine, alors vous êtes au

- Moover : Moteur pour abri de piscine jusqu'a abri - BMoover : Le moteur pour abri piscine ! Vous avez investi dans un abri de piscine mais quand il s’agit de profiter de votre piscine, il vous faut l’ouvrir et le refermer une fois la baignade terminée. Si vous êtes à la recherche d’une solution pour motoriser votre abri de piscine, alors vous êtes au

- Volet immergé piscine moteur dans l'axe Roussillon IILe volet immergé piscine ROUSSILLON moteur dans l'axe est la solution idéale pour couvrir et sécurisé sa piscine. Le moteur est situé dans l'axe. C'est le modèle idéal quand la piscine est déjà en eau. Ce volet immergé est fabriqué en France, il est aussi conforme à la norme NF P90-308. Prix à partir de : piscine de 5.00 x 3.00 m Sans escalier - Caillebotis ALU - Sans cloison de séparation (hors transport) - Volet immergé piscine ECA ROUSSILLON Moteur dans l'axe Enrouleur complet avec moteur dans l'axe. Axe + moteur et coffret garantie 4 ans + coffret avec contact pour électrolyseur au sel . Commutateur à clé déportée 3 positions avec contact maintenue . Dimensions maxi 8.03 x 12.00 m Avec Fin de course intégré Lames de couleur au même prix que les blanches !! Lames 71 mm - épaisseur 17 mm. PVC traité anti-tâche et anti UV Les lames sont fabriquées en PVC stabilisé au calcium de ZINC afin d'éviter les tâches. A chaque extrémité de la lame, des bouchons soudés assurent l'étanchéité du tablier. Des ailettes de 20 mm assurent la finition. Système de sécurité : Le nombre de système de sécurité est déterminé par la largueur du bassin. En fonction des cotes fournies sur la fiche de fabrication, ECA se réserve le droit de modifier le nombre de système de sécurité. Ces chiffres sont indiqués sous réserve et seront considérablement plus élevés dans des climats plus chauds et en cas de vent. < à 3 m = 2 par largueur de 3 à 5 m = 3 par largueur de 5 à 7 m = 4 par largueur En option : système de sécurité sur arase. Caillebotis conforme à la norme NF P-90-308 : Le caillebotis repose d'une part sur la poutrelle et d'autre part sur le mesure de l'arase. Nos caillebotis sont composés de lame de 125 mm. Nous vous rappelons qu'il n'est pas possible de couper les lames pour en réduire la largueur ( prévoir découpe des margelles ). 3 types de caillebotis : En aluminium double face blanc. ( sable et gris en option ). En bois IPE ( en option ) En composite de couleur bois ou gris ( en option ) 2 tailles : 700 x 1000 mm. 900 x 1000 ( en option ) Sur mesure ( en option ) Poutrelle en aluminium au choix ! Poutrelle en alu de 100 x 70 mm 3 couleurs : boitier réglable, boitier à fixer sur la paroi Poutrelle en alu de 100 x 110 mm 3 couleurs : boitier réglable, boitier à fixer sur la paroi, boitier pour profil liner horizontal, boitier profil liner vertical Blanche, sable ou grise

- Volet immergé piscine moteur dans l'axe Roussillon IILe volet immergé piscine ROUSSILLON moteur dans l'axe est la solution idéale pour couvrir et sécurisé sa piscine. Le moteur est situé dans l'axe. C'est le modèle idéal quand la piscine est déjà en eau. Ce volet immergé est fabriqué en France, il est aussi conforme à la norme NF P90-308. Prix à part

- Robot de piscine Bestway Ruby Tri-moteursRobot piscine Bestway Ruby Tri-moteurs - Technologie sans fil Nettoyage optimisé du fond et des parois jusqu’à la ligne d’eau Ruby est un petit joyau dans l’univers des robots électriques pour piscines : il allie les avantages de la technologie sans fil à l’aisance de déplacement des robots électriques équipés de 3 moteurs. Fini les càbles emmêlés ou trop courts pour aller nettoyer correctement les angles de la piscine, le robot Bestway Ruby a toute la liberté nécessaire pour se déplacer partout à l’intérieur de votre piscine et il a la puissance nécessaire pour remonter les parois pour y aspirer les saletés qui s’y déposent. La puissance de ses 3 moteurs lui permet de se déplacer et monter aux parois sans affaiblir la puissance d’aspiration et donc conserver une qualité de filtration constante au cours de son cycle de nettoyage de 90 minutes. La batterie qui équipe le robot Ruby lui permet d’avoir la puissance nécessaire pour effectuer un nettoyage d’entretien complet en 90 minutes, elle pourra être rechargée en 7 à 8 heures une fois le robot sec et connecté à une source d’alimentation. Son poids plume lui permet d’être mis à l’eau et ressorti très facilement sans effort conséquent pour que le nettoyage de la piscine ne soit plus une contrainte. Le capteur d’eau qu’il embarque lui permet de démarrer automatiquement lorsque vous le plongez dans l’eau et commencer ainsi son travail de nettoyage. Les cassettes filtrantes qui équipent ce modèle Ruby ont une capacité importante pour lui permettre d’aller au bout de son cycle de nettoyage sans arrêt prématuré pour motif de filtre plein, et elles ont une capacité de filtration de 180 microns qui est particulièrement adaptée aux piscines où l’on retrouves des débris végétaux, morceaux de feuilles, terre, etc... Ruby détectera automatiquement sa sortie de l’eau gràce à ce même capteur et se coupera donc pour préserver totalement son moteur. Qualité de conception et de fabrication Bestway Gràce à son savoir-faire, Bestway propose aujourd’hui le modèle Ruby, un robot autonome qui vous libère des contraintes des càbles et permet un nettoyage efficace du fond à la ligne d’eau, adapté à tout type de piscine. La batterie Lithium-ion permet de conserver des performances constantes tout au long du cycle de nettoyage. C’est un élément technique important trop souvent négligé et qui sera pourtant déterminant pour une durée de vie optimale. Ruby n’est retenu par aucun càble, cela lui permet d’avoir une amplitude maximale pour ses déplacements. Plus petit et plus léger qu’un robot électrique classique, il sera plus facile à manipuler et vous facilitera grandement l’entretien de votre piscine. Pour quelles piscines ? Tout type de piscines hors-sol ou enterrées jusqu’à 8 x 4m Tout type de formes Fond plat et pentes composées jusqu’à 30° Tout revêtement (liner, carrelage, béton peint, coque, etc...) Informations complémentaires Batterie rechargeable : Lithium-ion 8800 mAh Autonomie de la batterie : 1h30 (soit 90...

- Aucun VEVOR-Moteur de pompe de piscine, cadre 56Y, 1/1 V, 115V, 230 tr/min, 60Hz, 3450 tr/min, casse-tête,VEVOR-Moteur de pompe de piscine, cadre 56Y, 1/1 V, 115V, 230 tr/min, 60Hz, 3450 tr/min, casse-tête,

- VEVOR 110 V/230 V pompe de piscine 1.5HP/1HP moteur entrée/hors terre entrée/sortie 41/47.6/ piedsVEVOR 110 V/230 V pompe de piscine 1.5HP/1HP moteur entrée/hors terre entrée/sortie 41/47.6/ pieds

- Aucun Pompe à moteur sans balais à énergie solaire, moteur de compteur de piscine, contrôle de chargePompe à moteur sans balais à énergie solaire, moteur de compteur de piscine, contrôle de charge

- homgeek Robot nettoyeur de piscine sans fil 30W, étanche, moteurs à double entraînement, aspirateur deRobot nettoyeur de piscine sans fil 30W, étanche, moteurs à double entraînement, aspirateur de

- Other Genkinno erian SE-Aspirateur de piscine robotique sans fil, moteur sans balais Max 100W, navigationGenkinno erian SE-Aspirateur de piscine robotique sans fil, moteur sans balais Max 100W, navigation

- Robot piscine Zodiac CNX 20Le robot aspirateur de piscine Zodiac CNX 20 est prévu pour le nettoyage des piscines jusqu'à 10x5 m. 2 programmes : Fond seul (1h30) / Fond, parois, ligne d'eau (2h30) Aspiration Vortex cyclonique : 30%+ puissante Compatible toutes formes, tous fonds, tous revêtements Double moteur de traction pour une motricité maximale Accès facile au filtre par le dessus du robot Capot transparent : visibilité de l'encrassement du filtre Ultra léger (8 kg)

- Robot piscine Zodiac OT 3200 Tornax - TILERobot piscine Zodiac OT 3200 Le robot de piscine électrique Zodiac Vortex OT 3200, il permet de nettoyer le fond et les parois pour votre piscine jusqu'à 9 x 4 m. Il permet grâce à ses brosses actives de décoller les débris pour être aspirés grâce à un puissant moteur. Toute la technologie ZODIAC à petit prix Mais le gros point fort de ce robot électrique OT3200, c'est son poids ! Seulement 5.5 kg. Le robot fond et paroi le plus léger du marché. Version TILD : Compatible tout revêtement : Liner, béton carrelage et coque polyester. - Robot piscine Tornax OT 3200 TILE by Zodiac Voici la nouvelle collection de robot fond + paroi de chez ZODIAC. Le robot Vortex OV3400 by zodiac. Zodiac a travaillé un nouveau look design et moderne tout en travaillant sur le poids grâce à des matériaux le plus léger possible. Robot Zodiac OT 3200 : Fiche technique

- Pompe piscine STA RITE PENTAIR de 16 m3/h (1CV ) - TriphaséPompe piscine STA - RITE modèle P-STR La pompe piscine STA - RITE est la pompe la plus haut de gamme, résistante à toutes épreuves, des rendement surpuissant, un moteur ultra silencieux. Le moteur bénéfice de la technologie PENTAIR éprouvé et efficace renforcé en fibre de verre, une turbine haute pression pour un débit maximale COMPATIBLE ELECTROLYSEUR - Pompe STA RITE 5P2R de 3/4 à 1.5 CV en mono La pompe STA - RITE de la série 5P2R est en matériau de synthèse renforcé à la fibre de verre et obtenue par moulage de haute précision. Moteur Moteur européen conforme aux normes “CE” et muni d’une protection IP 55. La conception spéciale du diffuseur assure un auto-amorçage très efficace. Embase La pompe STA RITE 5P2R est montée sur une embase surélevée, stable, rigide et antivibrations. La hauteur de l’embase préserve le moteur de l’humidité et des souillures. Collier d’assemblage Le collier d’assemblage, en acier inoxydable, permet un démontage rapide de l’ensemble et un accès aisé aux pièces mobiles. Obtenue par le moulage sous pression, la turbine est conçue pour délivrer une hauteur manométrique élevée. Sa finition et son équilibrage dynamique lui assurent un fonctionnement silencieux et un excellent rendement. Le couvercle transparent du préfiltre permet facilement de vérifier l’état de colmatage du panier. Le couvercle a un ø de 127 mm et résiste à une pression de 4 bar. le panier du préfiltre est verrouillable et protège la turbine des impuretés. Construction Le matériau utilisé pour la fabrication de la pompe sta rite et du préfiltre autorise une pression de service élevée. Testé pendant plusieurs années ce matériau a des caractéristiques incomparables et résiste même à des variations de températures importantes. Presse-étoupe Comme sur des millions de pompes STA-RITE une étanchéité parfaite est obtenue par le presse-étoupe en céramique de carbone finement polie et surfacée. Données Techniques La pompes de la série 5P2R est une pompe centrifuge qui est principalement conçue pour l’application dans la piscine, en combinaison avec un filtre de piscine.

- Pompe piscine STA RITE PENTAIR de 18 m3/h (1.5CV ) - TriphaséPompe piscine STA - RITE modèle P-STR La pompe piscine STA - RITE est la pompe la plus haut de gamme, résistante à toutes épreuves, des rendement surpuissant, un moteur ultra silencieux. Le moteur bénéfice de la technologie PENTAIR éprouvé et efficace renforcé en fibre de verre, une turbine haute pression pour un débit maximale COMPATIBLE ELECTROLYSEUR - Pompe STA RITE 5P2R de 3/4 à 1.5 CV en mono La pompe STA - RITE de la série 5P2R est en matériau de synthèse renforcé à la fibre de verre et obtenue par moulage de haute précision. Moteur Moteur européen conforme aux normes “CE” et muni d’une protection IP 55. La conception spéciale du diffuseur assure un auto-amorçage très efficace. Embase La pompe STA RITE 5P2R est montée sur une embase surélevée, stable, rigide et antivibrations. La hauteur de l’embase préserve le moteur de l’humidité et des souillures. Collier d’assemblage Le collier d’assemblage, en acier inoxydable, permet un démontage rapide de l’ensemble et un accès aisé aux pièces mobiles. Obtenue par le moulage sous pression, la turbine est conçue pour délivrer une hauteur manométrique élevée. Sa finition et son équilibrage dynamique lui assurent un fonctionnement silencieux et un excellent rendement. Le couvercle transparent du préfiltre permet facilement de vérifier l’état de colmatage du panier. Le couvercle a un ø de 127 mm et résiste à une pression de 4 bar. le panier du préfiltre est verrouillable et protège la turbine des impuretés. Construction Le matériau utilisé pour la fabrication de la pompe sta rite et du préfiltre autorise une pression de service élevée. Testé pendant plusieurs années ce matériau a des caractéristiques incomparables et résiste même à des variations de températures importantes. Presse-étoupe Comme sur des millions de pompes STA-RITE une étanchéité parfaite est obtenue par le presse-étoupe en céramique de carbone finement polie et surfacée. Données Techniques La pompes de la série 5P2R est une pompe centrifuge qui est principalement conçue pour l’application dans la piscine, en combinaison avec un filtre de piscine.

- Pompe piscine STA RITE PENTAIR de 12 m3/h en mono ( 3/4 CV )Pompe piscine STA - RITE modèle P-STR La pompe piscine STA - RITE est la pompe la plus haut de gamme, résistante à toutes épreuves, des rendement surpuissant, un moteur ultra silencieux. Le moteur bénéfice de la technologie PENTAIR éprouvé et efficace renforcé en fibre de verre, une turbine haute pression pour un débit maximale COMPATIBLE ELECTROLYSEUR - Pompe STA RITE 5P2R de 3/4 à 1.5 CV en mono La pompe STA - RITE de la série 5P2R est en matériau de synthèse renforcé à la fibre de verre et obtenue par moulage de haute précision. Moteur Moteur européen conforme aux normes “CE” et muni d’une protection IP 55. La conception spéciale du diffuseur assure un auto-amorçage très efficace. Embase La pompe STA RITE 5P2R est montée sur une embase surélevée, stable, rigide et antivibrations. La hauteur de l’embase préserve le moteur de l’humidité et des souillures. Collier d’assemblage Le collier d’assemblage, en acier inoxydable, permet un démontage rapide de l’ensemble et un accès aisé aux pièces mobiles. Obtenue par le moulage sous pression, la turbine est conçue pour délivrer une hauteur manométrique élevée. Sa finition et son équilibrage dynamique lui assurent un fonctionnement silencieux et un excellent rendement. Le couvercle transparent du préfiltre permet facilement de vérifier l’état de colmatage du panier. Le couvercle a un ø de 127 mm et résiste à une pression de 4 bar. le panier du préfiltre est verrouillable et protège la turbine des impuretés. Construction Le matériau utilisé pour la fabrication de la pompe sta rite et du préfiltre autorise une pression de service élevée. Testé pendant plusieurs années ce matériau a des caractéristiques incomparables et résiste même à des variations de températures importantes. Presse-étoupe Comme sur des millions de pompes STA-RITE une étanchéité parfaite est obtenue par le presse-étoupe en céramique de carbone finement polie et surfacée. Données Techniques La pompes de la série 5P2R est une pompe centrifuge qui est principalement conçue pour l’application dans la piscine, en combinaison avec un filtre de piscine.

- Robot piscine Zodiac CNX 25Le robot aspirateur de piscine Zodiac CNX 25 est prévu pour le nettoyage des piscines jusqu'à 10x5 m. 2 programmes : Fond seul (1h30) et Fond, parois, ligne d'eau (2h30) Aspiration Vortex cyclonique : 30%+ puissante Compatible toutes formes, tous fonds, tous revêtements Double moteur de traction pour une motricité maximale Accès facile au filtre par le dessus du robot Capot transparent : visibilité de l'encrassement du filtre Double filtration : finesse de filtration 150/60 µ via deux bacs filtratns Ultra léger (8 kg)

- Pompe piscine STA RITE PENTAIR de 12 m3/h ( 3/4 CV ) - TriphaséPompe piscine STA - RITE modèle P-STR La pompe piscine STA - RITE est la pompe la plus haut de gamme, résistante à toutes épreuves, des rendement surpuissant, un moteur ultra silencieux. Le moteur bénéfice de la technologie PENTAIR éprouvé et efficace renforcé en fibre de verre, une turbine haute pression pour un débit maximale COMPATIBLE ELECTROLYSEUR - Pompe STA RITE 5P2R de 3/4 à 1.5 CV en mono La pompe STA - RITE de la série 5P2R est en matériau de synthèse renforcé à la fibre de verre et obtenue par moulage de haute précision. Moteur Moteur européen conforme aux normes “CE” et muni d’une protection IP 55. La conception spéciale du diffuseur assure un auto-amorçage très efficace. Embase La pompe STA RITE 5P2R est montée sur une embase surélevée, stable, rigide et antivibrations. La hauteur de l’embase préserve le moteur de l’humidité et des souillures. Collier d’assemblage Le collier d’assemblage, en acier inoxydable, permet un démontage rapide de l’ensemble et un accès aisé aux pièces mobiles. Obtenue par le moulage sous pression, la turbine est conçue pour délivrer une hauteur manométrique élevée. Sa finition et son équilibrage dynamique lui assurent un fonctionnement silencieux et un excellent rendement. Le couvercle transparent du préfiltre permet facilement de vérifier l’état de colmatage du panier. Le couvercle a un ø de 127 mm et résiste à une pression de 4 bar. le panier du préfiltre est verrouillable et protège la turbine des impuretés. Construction Le matériau utilisé pour la fabrication de la pompe sta rite et du préfiltre autorise une pression de service élevée. Testé pendant plusieurs années ce matériau a des caractéristiques incomparables et résiste même à des variations de températures importantes. Presse-étoupe Comme sur des millions de pompes STA-RITE une étanchéité parfaite est obtenue par le presse-étoupe en céramique de carbone finement polie et surfacée. Données Techniques La pompes de la série 5P2R est une pompe centrifuge qui est principalement conçue pour l’application dans la piscine, en combinaison avec un filtre de piscine.

- Pompe piscine STA RITE PENTAIR de 8m3/h en mono ( 1/2 CV )Pompe piscine STA RITE modèle P-STR La pompe piscine STA RITE P-STR est la pompe la plus haut de gamme, résistante à toutes épreuves, des rendement surpuissant, un moteur ultra silencieux. Le moteur bénéfice de la technologie PENTAIR éprouvé et efficace renforcé en fibre de verre, une turbine haute pression pour un débit maximale COMPATIBLE ELECTROLYSEUR - Pompe piscine STA RITE modèle P-STR : Ancienne 5P2R La pompe STA - RITE de la série P-STR est en matériau de synthèse renforcé à la fibre de verre et obtenue par moulage de haute précision. Moteur Moteur européen conforme aux normes “CE” et muni d’une protection IP 55. La conception spéciale du diffuseur assure un auto-amorçage très efficace. Embase La pompe STA RITE P-STR est montée sur une embase surélevée, stable, rigide et antivibrations. La hauteur de l’embase préserve le moteur de l’humidité et des souillures. Collier d’assemblage Le collier d’assemblage, en acier inoxydable, permet un démontage rapide de l’ensemble et un accès aisé aux pièces mobiles. Obtenue par le moulage sous pression, la turbine est conçue pour délivrer une hauteur manométrique élevée. Sa finition et son équilibrage dynamique lui assurent un fonctionnement silencieux et un excellent rendement. Le couvercle transparent du préfiltre permet facilement de vérifier l’état de colmatage du panier. Le couvercle a un ø de 127 mm et résiste à une pression de 4 bar. le panier du préfiltre est verrouillable et protège la turbine des impuretés. Construction Le matériau utilisé pour la fabrication de la pompe sta rite et du préfiltre autorise une pression de service élevée. Testé pendant plusieurs années ce matériau a des caractéristiques incomparables et résiste même à des variations de températures importantes. Presse-étoupe Comme sur des millions de pompes STA-RITE une étanchéité parfaite est obtenue par le presse-étoupe en céramique de carbone finement polie et surfacée. Données Techniques La pompes de la série 5P2R est une pompe centrifuge qui est principalement conçue pour l’application dans la piscine, en combinaison avec un filtre de piscine. Fiche technique Pompe PENTAIR : STA RITE modèle P-STR : Ancienne 5P2R

- Robot piscine Zodiac OT 3200 Tornax - TILERobot piscine Zodiac OT 3200 Le robot de piscine électrique Zodiac Vortex OT 3200, il permet de nettoyer le fond et les parois pour votre piscine jusqu'à 9 x 4 m. Il permet grâce à ses brosses actives de décoller les débris pour être aspirés grâce à un puissant moteur. Toute la technologie ZODIAC à

News and research before you hear about it on CNBC and others. Claim your 1-week free trial to StreetInsider Premium here.

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 6-K

REPORT OF FOREIGN PRIVATE ISSUER PURSUANT TO RULE 13a-16 OR 15d-16

UNDER THE SECURITIES EXCHANGE ACT OF 1934

For the month of August 2020

Commission File Number: 001-33153

ENDEAVOUR SILVER CORP.

(Translation of registrant’s name into English)

#1130-609 Granville Street

Vancouver, British Columbia, Canada V7Y 1G5

(Address of principal executive offices)

Indicate by check mark whether the registrant files or will file annual reports under cover Form 20-F or Form 40-F.

[ ] Form 20-F [ x ] Form 40-F

Indicate by check mark if the registrant is submitting the Form 6-K in paper as permitted by Regulation S-T Rule 101(b)(1): [ ]

Indicate by check mark if the registrant is submitting the Form 6-K in paper as permitted by Regulation S-T Rule 101(b)(7): [ ]

Indicate by check mark whether by furnishing the information contained in this Form, the registrant is also thereby furnishing the information to the Commission pursuant to Rule 12g3-2(b) under the Securities Exchange Act of 1934.

Yes [ ] No [ x ]

If « Yes » is marked, indicate below the file number assigned to the registrant in connection with Rule 12g3-2(b): 82- _________

SUBMITTED HEREWITH

Exhibits

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the undersigned, thereunto duly authorized.

| Endeavour Silver Corp. | ||

| (Registrant) | ||

| Date: August 6, 2020 | By: | /s/ Bradford Cooke |

| Bradford Cooke | ||

| Title: | CEO | |

|

|

|

104698-02-RPT-001 |

Endeavour Silver Corp

|

NI 43-101 Technical Report |

July 31, 2020 |

Prepared for: Endeavour Silver Corp.

Prepared by: Ausenco Engineering Canada

Qualified Persons

Robin Kalanchey, P.Eng. – Ausenco Engineering Canada • Michael Petrina, P.Eng. – Moose Mountain Technical Services • Humberto F. Preciado, P.E. – Wood • Eugene Puritch, P.Eng., FEC, CET – P&E Mining Consultants Inc. • David Burga, P.Geo. – P&E Mining Consultants Inc. • Yungang Wu, P.Geo. – P&E Mining Consultants Inc. • Michael Levy, P.Eng. – JDS Energy & Mining Inc. • Eugenio Iasillo, P.E. – Process Engineering LLC

TABLE OF CONTENTS

| 1 Summary | 1-1 |

| 1.1 Overview | 1-1 |

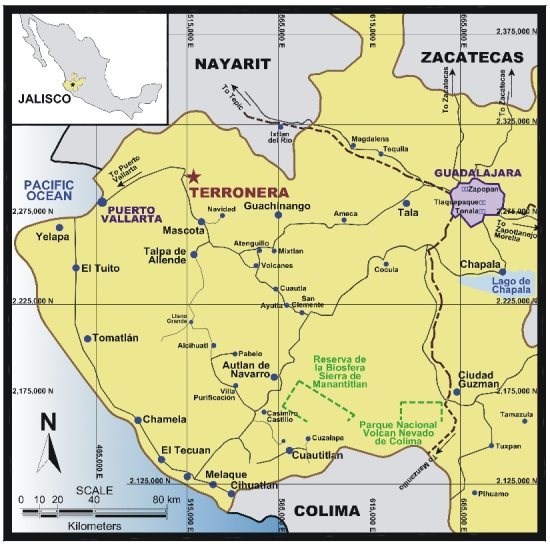

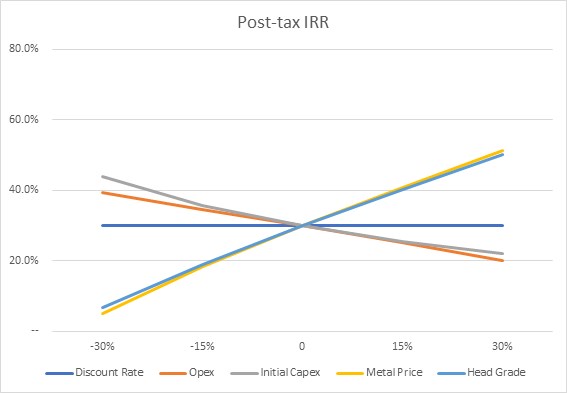

| 1.2 Property Description and Location | 1-1 |

| 1.3 Accessibility, Climate, Local Resources, Infrastructure & Physiography | 1-2 |

| 1.4 History | 1-3 |

| 1.5 Geology and Mineralization | 1-5 |

| 1.6 Deposit Types | 1-5 |

| 1.7 Exploration | 1-5 |

| 1.8 Drilling | 1-6 |

| 1.9 Sample Preparation, Analyses and Security | 1-7 |

| 1.10 Data Verification | 1-7 |

| 1.11 Mineral Processing and Metallurgical Testing | 1-7 |

| 1.12 Mineral Resource Estimate | 1-10 |

| 1.13 Mineral Reserve Estimate | 1-11 |

| 1.14 Mining Methods | 1-12 |

| 1.15 Recovery Methods | 1-15 |

| 1.16 Project Infrastructure | 1-18 |

| 1.16.1 Access | 1-18 |

| 1.16.2 Power | 1-18 |

| 1.16.3 Tailings Storage Facility | 1-18 |

| 1.16.4 Accommodation | 1-19 |

| 1.16.5 Buildings | 1-19 |

| 1.16.6 Water Management | 1-19 |

| 1.17 Market Studies and Contracts | 1-19 |

| 1.18 Environmental Studies, Permitting, and Social or Community Impact | 1-20 |

| 1.19 Capital and Operating Costs | 1-20 |

| 1.19.1 Capital Cost | 1-20 |

| 1.19.2 Operating Cost | 1-21 |

| 1.20 Economic Analysis | 1-22 |

| 1.20.1 Financial Model Parameters | 1-22 |

| 1.20.2 Economic Analysis | 1-22 |

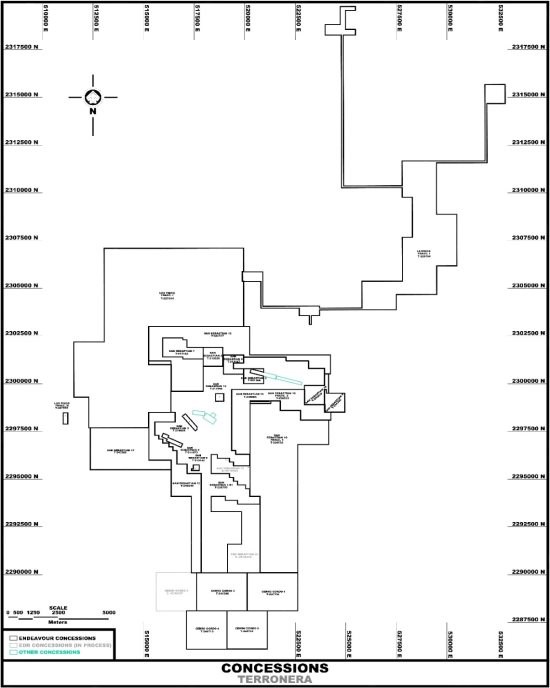

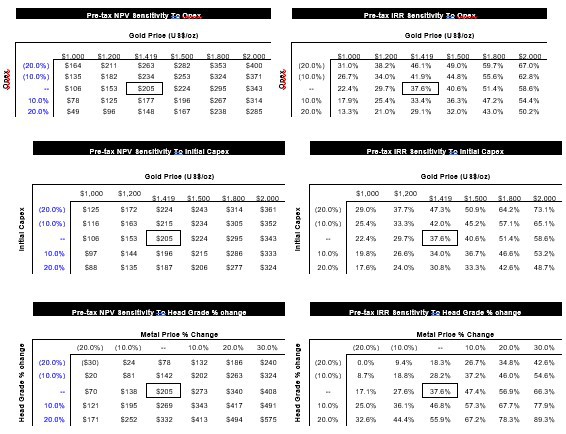

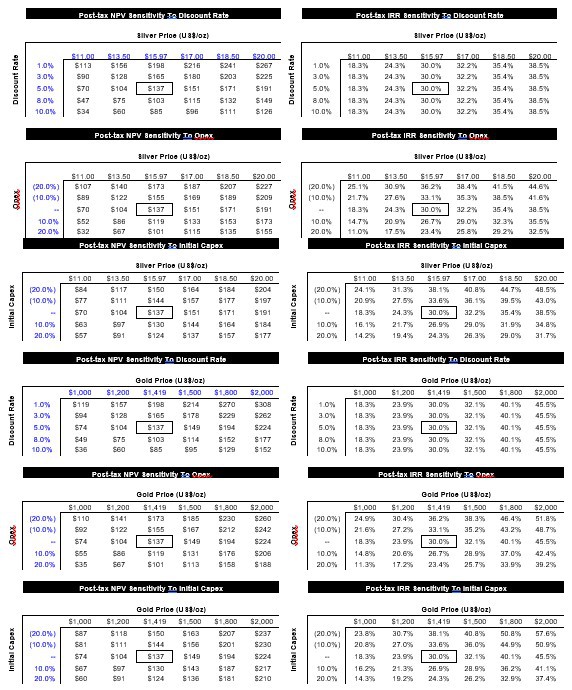

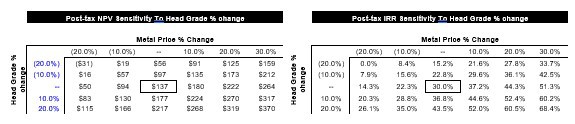

| 1.20.3 Sensitivity Analysis | 1-24 |

| 1.21 Conclusions and Recommendations | 1-27 |

| 1.21.1 Overall | 1-27 |

| 1.21.2 Exploration | 1-27 |

| 1.21.3 Mineral Resource Estimations | 1-27 |

| 1.21.4 Mineral Reserve and Mining Methods | 1-28 |

| 1.21.5 Metallurgical Testwork | 1-28 |

| 1.21.6 Recovery Methods | 1-29 |

| 1.21.7 Site Infrastructure | 1-29 |

| 1.21.8 Water Management | 1-29 |

| 1.21.9 Tailings Management Facility | 1-30 |

| 1.21.10 Environmental, Permitting & Community Relations | 1-30 |

| 2 Introduction | 2-1 |

| 2.1 Introduction | 2-1 |

104698-02-RX-RPT-001

Rev: A

Date: July 31, 2020

| 2.2 Terms of Reference | 2-1 |

| 2.3 Sources of Information | 2-1 |

| 2.4 Qualified Persons | 2-1 |

| 2.5 Site Visits and Scope of Personal Inspection | 2-2 |

| 2.6 Effective Dates | 2-2 |

| 2.7 Previous Technical Reports | 2-2 |

| 2.8 Units and Currency | 2-3 |

| 3 Reliance on Other Experts | 3-1 |

| 3.1 Legal Status | 3-1 |

| 3.2 Baseline Studies, Environmental, and Permitting | 3-1 |

| 4 Property Description and Location | 4-1 |

| 4.1 Location | 4-1 |

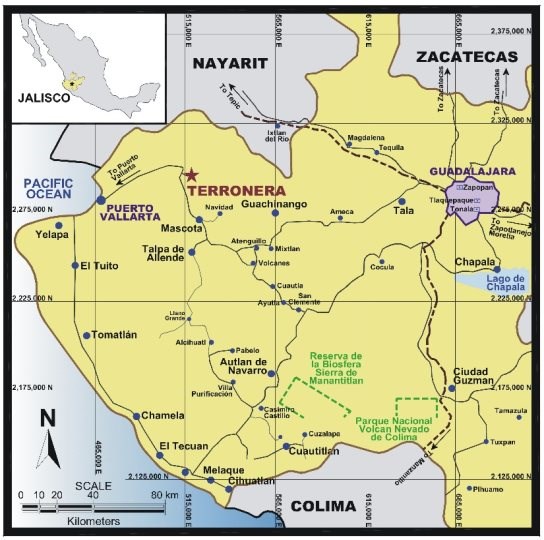

| 4.2 Mexican Regulations for Mineral Concessions | 4-2 |

| 4.3 Property Description and Tenure | 4-2 |

| 4.4 Surface Rights | 4-6 |

| 4.5 Water Rights | 4-7 |

| 4.6 Royalties and Encumbrances | 4-7 |

| 4.7 Permitting Considerations | 4-7 |

| 4.8 Environmental Considerations | 4-7 |

| 4.9 Social License Considerations | 4-7 |

| 4.10 QP Comments on « Item 4; Property Description and Location » | 4-7 |

| 5 Accessibility, Climate, Local Resources, Infrastructure and Physiography | 5-1 |

| 5.1 Accessibility | 5-1 |

| 5.2 Local Resources and Infrastructure | 5-1 |

| 5.3 Climate | 5-1 |

| 5.4 Physiography | 5-1 |

| 5.5 Infrastructure | 5-2 |

| 6 History | 6-1 |

| 6.1 San Sebastian Del Oeste Mining District | 6-1 |

| 6.2 Previous Mineral Resource and Mineral Reserve Estimates | 6-2 |

| 6.3 Past Production History | 6-4 |

| 7 Geological Setting and Mineralization | 7-1 |

| 7.1 Regional Geology | 7-1 |

| 7.2 Local Geology | 7-2 |

| 7.3 Deposit Geology | 7-3 |

| 7.4 Structure | 7-4 |

| 7.5 Alteration | 7-4 |

| 7.6 Mineralization | 7-4 |

| 8 Deposit Types | 8-1 |

| 8.1 Low-Sulphidation Epithermal Deposits | 8-1 |

| 8.1.1 Geological Setting | 8-1 |

| 8.1.2 Mineralization | 8-1 |

| 8.1.3 Alteration | 8-2 |

| 8.2 Applicability of the Low-Sulphidation Model to the Terronera Project | 8-2 |

| 8.3 QP Comments on « Item 8: Deposit Types » | 8-3 |

| 9 Exploration | 9-1 |

| 9.1 Grids and Surveys | 9-1 |

104698-02-RX-RPT-001

Rev: A

Date: July 31, 2020

| 9.2 2010 to 2016 Endeavour Silver Exploration Programs | 9-1 |

| 9.3 2017 Exploration Program | 9-2 |

| 9.4 Terronera NW | 9-6 |

| 9.5 Quiteria West | 9-7 |

| 9.6 Los Espinos-La Guardarraya | 9-8 |

| 9.7 El Jabalí | 9-9 |

| 9.8 El Fraile | 9-11 |

| 9.9 Vista Hermosa | 9-12 |

| 9.10 La Escondida | 9-13 |

| 9.11 El Armadillo | 9-14 |

| 9.12 La Atrevida | 9-15 |

| 9.13 Santana | 9-16 |

| 9.14 Peña Gorda | 9-17 |

| 9.15 San Joaquin | 9-18 |

| 10 Drilling | 10-20 |

| 10.1 2011 to 2016 Drilling | 10-20 |

| 10.2 2011 Drilling Program | 10-20 |

| 10.3 2012 Drilling Program | 10-20 |

| 10.4 2013 Drilling Program | 10-21 |

| 10.5 2014 Drilling program | 10-22 |

| 10.6 2015 Drilling Program | 10-22 |

| 10.7 2016 Drilling Program | 10-23 |

| 10.8 2017 Drilling Program | 10-23 |

| 10.9 2018 Drilling Program | 10-28 |

| 10.10 Terronera | 10-28 |

| 10.11 La Luz | 10-38 |

| 11 Sample Preparation, Analyses and Security | 11-1 |

| 11.1 Introduction | 11-1 |

| 11.2 Sampling | 11-1 |

| 11.3 Sample Preparation and Analysis | 11-1 |

| 11.4 Quality Assurance/Quality Control Program | 11-2 |

| 11.5 Performance of Certified Reference Materials | 11-3 |

| 11.5.1 Re-Assays | 11-8 |

| 11.6 Duplicate Samples | 11-9 |

| 11.7 Performance of Blank Material | 11-10 |

| 11.7.1 Re-Assays | 11-14 |

| 11.8 Check Assays | 11-17 |

| 12 Data Verification | 12-1 |

| 12.1 Database Verification | 12-1 |

| 12.2 P&E Site Visits and Independent Sampling | 12-1 |

| 13 Mineral Processing and Metallurgical Testing | 13-1 |

| 13.1 Summary of Historical Metallurgical Testwork | 13-1 |

| 13.1.1 Metallurgical Samples | 13-1 |

| 13.1.2 Comminution Testing | 13-2 |

| 13.1.3 Primary Grind Size and Deleterious Elements | 13-3 |

| 13.1.4 Solid-Liquid Separation Testing | 13-3 |

| 13.1.5 New Metallurgical Testing | 13-4 |

| 13.1.6 Flotation Testwork | 13-5 |

104698-02-RX-RPT-001

Rev: A

Date: July 31, 2020

| 13.2 New Recovery Model | 13-6 |

| 14 Mineral Resource Estimates | 14-1 |

| 14.1 Terronera Deposit Mineral Resource Estimate | 14-1 |

| 14.1.1 Introduction | 14-1 |

| 14.1.2 Database | 14-1 |

| 14.1.3 Data Verification | 14-3 |

| 14.1.4 Domain Interpretation | 14-3 |

| 14.1.5 Model Rock Code Determination | 14-5 |

| 14.1.6 Compositing | 14-5 |

| 14.1.7 Grade Capping | 14-6 |

| 14.1.8 Semi-Variography | 14-11 |

| 14.1.9 Bulk Density | 14-13 |

| 14.1.10 Block Modeling | 14-13 |

| 14.1.11 Mineral Resource Classification | 14-14 |

| 14.1.12 Mineral Resource Estimate Cut-off | 14-14 |

| 14.1.13 Mineral Resource Estimate | 14-15 |

| 14.1.14 Confirmation of Estimate | 14-17 |

| 14.1.15 Figures and Maps Pertaining to the Mineral Resource Estimate for the Terronera Deposit | 14-20 |

| 14.2 La Luz Deposit Mineral Resource Estimate | 14-31 |

| 14.2.1 Introduction | 14-31 |

| 14.2.2 Data Verification | 14-31 |

| 14.2.3 Database | 14-31 |

| 14.2.4 Domain Interpretation | 14-34 |

| 14.2.5 Model Rock Code Determination | 14-36 |

| 14.2.6 Compositing | 14-36 |

| 14.2.7 Grade Capping | 14-37 |

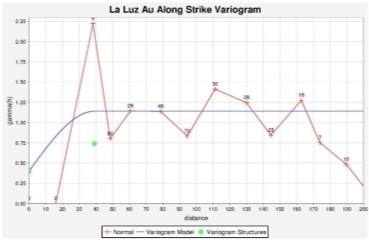

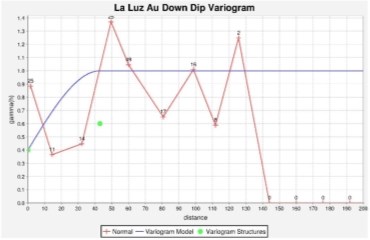

| 14.2.8 Semi-Variography | 14-38 |

| 14.2.9 Bulk Density | 14-41 |

| 14.2.10 Block Modelling | 14-41 |

| 14.2.11 Mineral Resource Classification | 14-42 |

| 14.2.12 Mineral Resource Estimate Cut-off | 14-42 |

| 14.2.13 La Luz Mineral Resource Estimate | 14-43 |

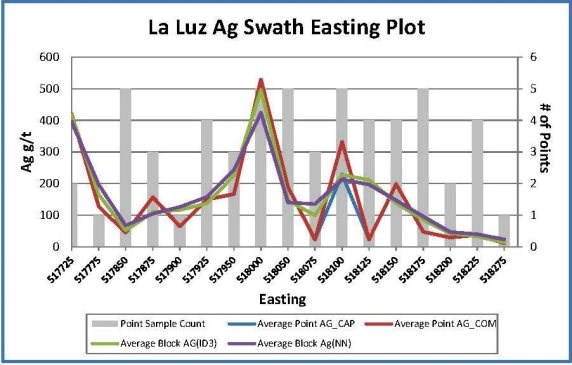

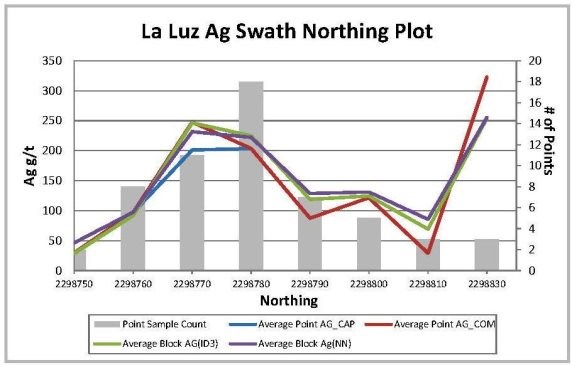

| 14.2.14 Confirmation of Estimate | 14-45 |

| 14.2.15 Figures and Maps Pertaining to the Mineral Resource Estimate for the La Luz Deposit | 14-50 |

| 15 Mineral Reserve Estimates | 15-1 |

| 15.1 Cut-Off Grade | 15-1 |

| 15.2 Mining Dilution | 15-2 |

| 15.3 Mining Recovery | 15-3 |

| 15.4 Mineral Reserve Table | 15-3 |

| 15.5 Factors That May Affect the Mineral Reserve Estimate | 15-4 |

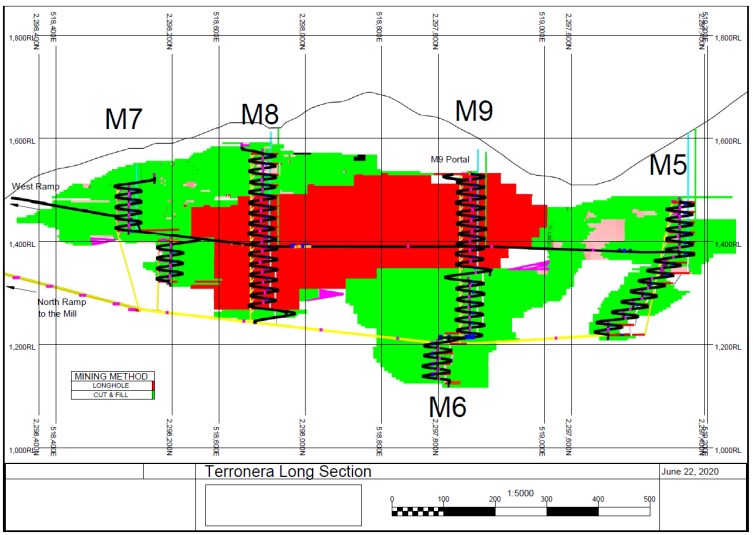

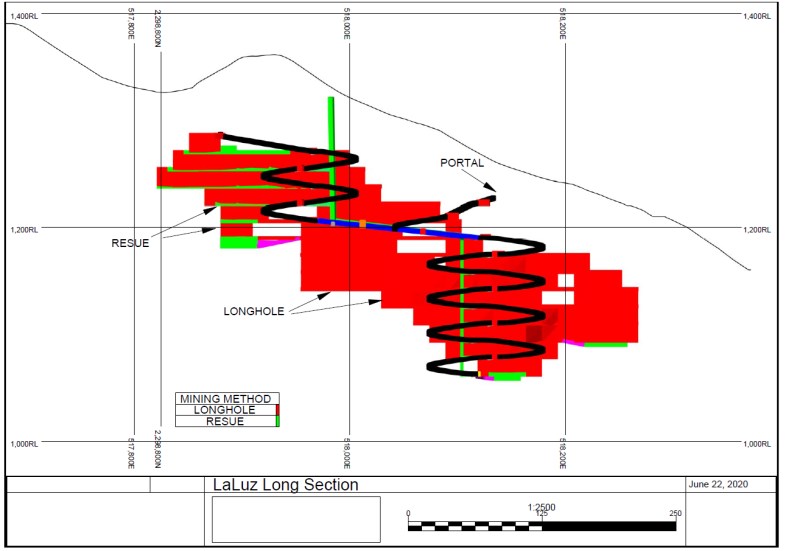

| 16 Mining Methods | 16-1 |

| 16.1 Introduction | 16-1 |

| 16.2 Geotechnical Considerations | 16-6 |

| 16.2.1 Geotechnical Characterization | 16-6 |

| 16.2.2 Geotechnical Domains and Rock Mass Properties | 16-6 |

| 16.2.3 In-Situ Stresses | 16-8 |

| 16.2.4 Empirical Stope Design Analysis | 16-10 |

| 16.2.5 Estimates of Unplanned Dilution | 16-13 |

| 16.2.6 Backfill Strength Requirements | 16-13 |

| 16.2.7 Ground Support | 16-14 |

104698-02-RX-RPT-001

Rev: A

Date: July 31, 2020

| 16.3 Backfill | 16-15 |

| 16.4 Waste Development | 16-16 |

| 16.4.1 Lateral Development | 16-16 |

| 16.4.2 Vertical Development | 16-17 |

| 16.5 Longhole Retreat Mining with Backfill | 16-17 |

| 16.6 Mechanized Cut and Fill Mining | 16-18 |

| 16.6.1 Resue Mining | 16-19 |

| 16.7 Representative Drawings | 16-19 |

| 16.8 Schedules | 16-20 |

| 16.8.1 Development | 16-20 |

| 16.8.2 Production | 16-20 |

| 16.9 Services | 16-24 |

| 16.9.1 Ventilation | 16-24 |

| 16.9.2 Electrical | 16-24 |

| 16.9.3 Dewatering | 16-24 |

| 16.9.4 Compressed Air | 16-25 |

| 16.9.5 Egresses, Refuges and Additional Underground Infrastructure | 16-25 |

| 16.10 Equipment | 16-25 |

| 16.11 Material Handling | 16-27 |

| 16.11.1 Ore Handling | 16-27 |

| 16.11.2 Waste Handling | 16-27 |

| 16.11.3 Backfill Handling | 16-28 |

| 17 Recovery Methods | 17-1 |

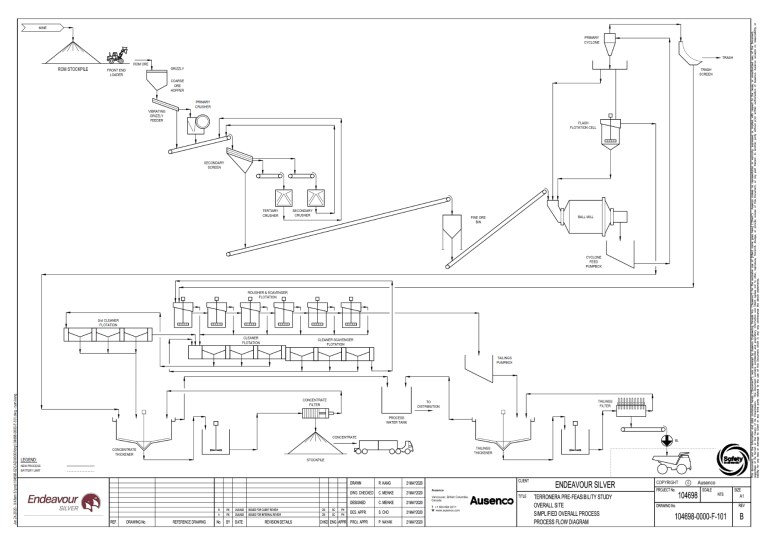

| 17.1 Overall Process Design | 17-1 |

| 17.2 Process Plant Description | 17-3 |

| 17.2.1 Process Design Criteria | 17-4 |

| 17.2.2 Crushing and Stockpiling | 17-6 |

| 17.2.3 Grinding Circuit | 17-6 |

| 17.2.4 Flash Flotation | 17-6 |

| 17.2.5 Flotation and Concentrate Thickening | 17-6 |

| 17.2.6 Tailings Thickening | 17-7 |

| 17.2.7 Reagent Handling and Storage | 17-7 |

| 17.2.8 Power Requirements | 17-7 |

| 17.2.9 Water Requirements | 17-8 |

| 18 Project Infrastructure | 18-1 |

| 18.1 Existing Infrastructure | 18-1 |

| 18.2 Proposed Infrastructure | 18-1 |

| 18.3 Process Plant | 18-1 |

| 18.4 Tailings Filter Plant | 18-1 |

| 18.5 Temporary Waste Rock Storage Facilities | 18-3 |

| 18.6 Ancillary Buildings | 18-3 |

| 18.7 Camp Facilities | 18-3 |

| 18.8 Internal Haul Roads and Mine Access Infrastructure | 18-3 |

| 18.9 Power Supply and Distribution | 18-4 |

| 18.10 Water Supply and Distribution | 18-4 |

| 18.11 Waste Management | 18-4 |

| 18.12 Surface Water Control | 18-4 |

| 18.13 Communications | 18-4 |

| 19 Market Studies and Contracts | 19-1 |

| 19.1 Market Studies | 19-1 |

104698-02-RX-RPT-001

Rev: A

Date: July 31, 2020

| 19.2 Commodity Prices | 19-1 |

| 19.3 Contracts | 19-2 |

| 20 Environmental Studies, Permitting and Social or Community Impact | 20-1 |

| 20.1 Permitting Basis | 20-1 |

| 20.2 Existing Site Conditions | 20-6 |

| 20.2.1 Baseline Studies | 20-6 |

| 20.2.2 Topography | 20-7 |

| 20.2.3 Meteorology – Air Quality | 20-7 |

| 20.2.4 Soil | 20-7 |

| 20.2.5 Geotechnical and Seismic Studies | 20-8 |

| 20.2.6 Hydrology | 20-8 |

| 20.2.7 Watershed – Surface Hydrology | 20-9 |

| 20.2.8 Sub-Surface Hydrology | 20-9 |

| 20.2.9 Land Use | 20-9 |

| 20.2.10 Vegetation and Ecosystems | 20-9 |

| 20.3 Dry-Stack Tailings Storage Facility | 20-10 |

| 20.3.1 Design Considerations | 20-10 |

| 20.3.2 TSF Location and Geometry | 20-12 |

| 20.3.3 TSF Operating Methodology | 20-12 |

| 20.3.4 Tailings Transport and Deposition | 20-12 |

| 20.4 Terronera and La Luz Waste Rock Dumps | 20-12 |

| 20.4.1 Terronera Temporary Waste Dump | 20-12 |

| 20.4.2 La Luz Temporary WRSF | 20-13 |

| 20.5 Environmental Considerations for Tailings Storage | 20-14 |

| 20.5.1 Substances and Residues Used and Produced by the Ore Processing Operations | 20-14 |

| 20.5.2 Geotechnical Characterization of the Starter Dam Structure and Filtered Tailings Storage | 20-14 |

| 20.5.3 Environmental Monitoring Program | 20-15 |

| 20.5.4 Surface Water Management | 20-17 |

| 20.5.5 Mine Water Discharge | 20-17 |

| 20.5.6 Groundwater Management | 20-17 |

| 20.5.7 Air Quality Management | 20-18 |

| 20.5.8 Soil-Rock Management as Closure Capping Materials | 20-18 |

| 20.5.9 Solid Waste Disposal | 20-18 |

| 20.6 Socio-Economic and Community Relations | 20-18 |

| 20.7 Cultural and Historical Resource Studies | 20-18 |

| 20.8 Archeological Artifacts and Studies | 20-18 |

| 20.9 Reclamation and Closure Activities | 20-19 |

| 20.9.1 Mine Surface Disturbance Closure Activities | 20-19 |

| 20.9.2 Underground Mine Infrastructure Closure Activities | 20-19 |

| 21 Capital and Operating Costs | 21-1 |

| 21.1 Capital Cost | 21-1 |

| 21.1.1 Summary | 21-1 |

| 21.1.2 Exchange Rates | 21-2 |

| 21.1.3 Detailed Discipline Direct Costs | 21-3 |

| 21.1.4 Initial Indirect Capital Costs | 21-9 |

| 21.1.5 Estimate Provisions | 21-11 |

| 21.1.6 Exclusions | 21-12 |

| 21.1.7 Growth (Design) Allowance | 21-12 |

| 21.2 Sustaining Capital Costs | 21-13 |

| 21.3 Mine Closure Costs | 21-13 |

| 21.4 Operating Cost Estimates | 21-13 |

104698-02-RX-RPT-001

Rev: A

Date: July 31, 2020

| 21.4.1 Summary | 21-13 |

| 21.4.2 Mine Operating Costs | 21-14 |

| 21.4.3 Process Plant Operating Costs | 21-16 |

| 21.4.4 Dry-Stack Tailings Storage Facility Operating Costs | 21-19 |

| 22 Economic Analysis | 22-1 |

| 22.1 Cautionary Statement | 22-1 |

| 22.2 Methodology Used | 22-2 |

| 22.3 Financial Model Parameters | 22-2 |

| 22.4 Taxes | 22-2 |

| 22.5 Working Capital | 22-3 |

| 22.6 Closure Costs & Salvage Value | 22-3 |

| 22.7 Royalty | 22-3 |

| 22.8 Economic Analysis | 22-3 |

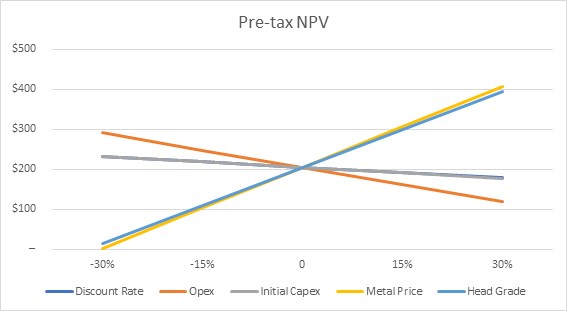

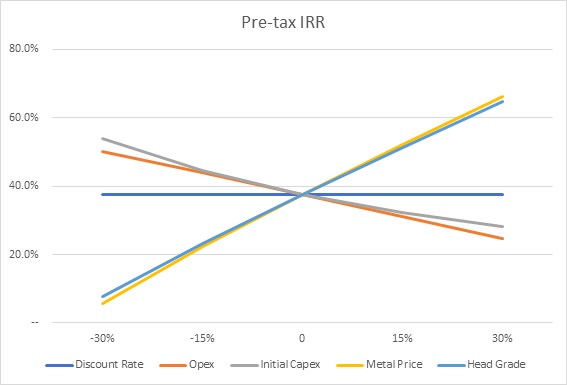

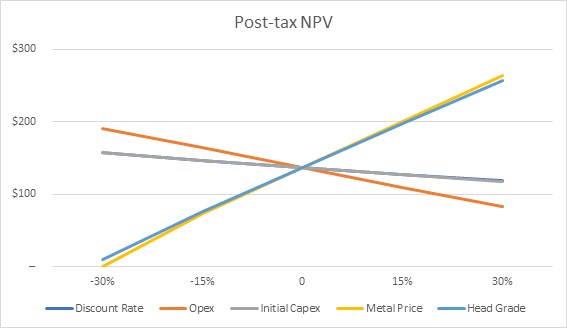

| 22.9 Sensitivity Analysis | 22-9 |

| 23 Adjacent Properties | 23-1 |

| 24 Other Relevant Data and Information | 24-1 |

| 25 Interpretation and Conclusions | 25-1 |

| 25.1 Exploration | 25-1 |

| 25.2 Drilling | 25-1 |

| 25.3 Sample Preparation, Analyses & Security | 25-1 |

| 25.4 Data Verification | 25-1 |

| 25.5 Resources, Reserves and Mining | 25-2 |

| 25.5.1 Mineral Resource Estimate | 25-2 |

| 25.5.2 Mineral Reserve Estimate | 25-4 |

| 25.5.3 Mine Plan | 25-4 |

| 25.6 Metallurgical Testwork and Processing | 25-4 |

| 25.7 Site Infrastructure | 25-4 |

| 25.8 Environmental Studies, Permitting and Social Impact | 25-5 |

| 25.9 Capital & Operating Costs | 25-5 |

| 25.10 Economic Analysis | 25-5 |

| 25.11 Opportunities | 25-5 |

| 25.12 Risk | 25-6 |

| 26 Recommendations | 26-1 |

| 26.1 Drilling | 26-1 |

| 26.2 Mineral Resource Estimations | 26-1 |

| 26.3 Mineral Reserve and Mining Methods | 26-1 |

| 26.4 Metallurgical Testwork | 26-2 |

| 26.5 Recovery Methods | 26-2 |

| 26.6 Site Infrastructure | 26-3 |

| 26.7 Water Management | 26-3 |

| 26.8 Dry-Stack Tailings Management Facility | 26-3 |

| 26.9 Environmental, Permitting & Community Relations | 26-4 |

| 26.10 Costs | 26-4 |

| 27 References | 27-1 |

104698-02-RX-RPT-001

Rev: A

Date: July 31, 2020

LIST OF TABLES

| Table 1-1 | Summary of Historic Exploration on the San Sebastian Property | 1-3 |

| Table 1-2 | Bond Ball Mill Work Index Test Results | 1-8 |

| Table 1-3 | Comminution Testing Results | 1-8 |

| Table 1-4 | Summary of Fully Automatic Membrane Type Filter Press | 1-9 |

| Table 1-5 | Terronera Mineral Resource Estimate at a Cut-Off Grade of 150 g/t AgEq(1-6) | 1-10 |

| Table 1-6 | La Luz Mineral Resource Estimate at a Cut-Off Grade of 150 g/t AgEq(1-5) | 1-11 |

| Table 1-7 | Terronera and La Luz Probable Mineral Reserve(1-5) | 1-11 |

| Table 1-8 | Key Process Design Criteria for the Mill | 1-15 |

| Table 1-9 | Summary of Terronera Capital Cost Estimate | 1-20 |

| Table 1-10 | Average Annual Operating Costs (US$) | 1-21 |

| Table 1-11 | Summary of Project Economics | 1-23 |

| Table 1-12 | Sensitivity to Metal Prices | 1-27 |

| Table 1-13 | Sensitivity to CAPEX | 1-27 |

| Table 1-14 | Budget Estimate for Completing the Recommended Work | 1-27 |

| Table 2-1 | Terminology and Abbreviations | 2-3 |

| Table 4-1 | Concessions and Taxes on Each Concession | 4-2 |

| Table 4-2 | Summary of Endeavour Silver’s Surface Access Rights | 4-6 |

| Table 6-1 | Exploration History Summary | 6-1 |

| Table 10-1 | Terronera Project Surface Drilling in 2017 | 10-24 |

| Table 10-2 | 2017 Drill Hole Summary for the La Luz Surface Drilling Program | 10-25 |

| Table 10-3 | Surface Drill Hole Significant Assay Summary for Mineral Intercepts in the La Luz Vein Area | 10-27 |

| Table 10-4 | Terronera Surface Drilling in 2018 | 10-29 |

| Table 10-5 | 2018 Drill Hole Summary for the Terronera Surface Drilling Program | 10-29 |

| Table 10-6 | 2018 Drill Hole Assay Summary for the Terronera Surface Drilling Program | 10-32 |

| Table 11-1 | Summary of Control Samples Used for the 2018 Surface Exploration Program | 11-2 |

| Table 11-2 | Summary of the Reference Standard Material Samples Used During the Terronera Surface Diamond Drilling Program | 11-4 |

| Table 11-3 | Performance Limits for Standards Used at the Terronera Project | 11-4 |

| Table 11-4 | Company Protocol for Monitoring Standard Performance | 11-4 |

| Table 11-5 | Summary of Analysis of CRMs | 11-5 |

| Table 11-6 | Comparative Table of Original vs. Re-assay Values For Drill Hole TR15-7 | 11-8 |

| Table 11-7 | Comparative Table of Original Vs. Re-Assay Values for Drill Holes TR11-4 and TR11-8 | 11-13 |

| Table 11-8 | Comparative Table of Original vs. Re-assay Values for Drill Holes TR11-4 and TR11-8 | 11-15 |

| Table 13-1 | Samples Characterization and Head Assay, Fire Assay, and Whole Rock Analysis (%) | 13-1 |

| Table 13-2 | Cyanide Solubility of Composite Sample TR2015-1 | 13-2 |

| Table 13-3 | Bond Ball Mill Work Index Test Results | 13-2 |

| Table 13-4 | Comminution Testing Results | 13-3 |

| Table 13-5 | Summary of Fully Automatic Membrane Type Filter Press | 13-4 |

| Table 13-6 | 2020 Test Samples Head Assays | 13-5 |

| Table 14-1 | Terronera Drill Hole Database Summary | 14-1 |

| Table 14-2 | Model Rock Code Description and Volume | 14-5 |

| Table 14-3 | Basic Statistics of All Constrained Assays and Sample Length | 14-5 |

| Table 14-4 | Composite Summary Statistics | 14-6 |

| Table 14-5 | Silver Grade Capping Values | 14-9 |

| Table 14-6 | Gold Grade Capping Values | 14-10 |

| Table 14-7 | Terronera Block Model Definition | 14-13 |

| Table 14-8 | Gold and Silver Block Model Interpolation Parameters | 14-14 |

| Table 14-9 | Terronera Underground AgEq Cut-Off Grade Calculation | 14-15 |

| Table 14-10 | Terronera Mineral Resource Estimate at a Cut-off Grade of 150 g/t AgEq (1-5) | 14-15 |

104698-02-RX-RPT-001

Rev: A

Date: July 31, 2020

| Table 14-11 | Terronera Sensitivity of Mineral Resource Estimate to AgEq Cut-off | 14-16 |

| Table 14-12 | Average Grade Comparison of Composites with Block Model | 14-17 |

| Table 14-13 | Volumetric Comparison of Block Model with Geometric Wireframes | 14-17 |

| Table 14-14 | La Luz Model Rock Code Description and Volume | 14-36 |

| Table 14-15 | Basic Statistics of All Constrained Assays and Sample Length | 14-36 |

| Table 14-16 | Composite Summary Statistics | 14-37 |

| Table 14-17 | Grade Capping Values | 14-38 |

| Table 14-18 | La Luz Block Model Definition | 14-41 |

| Table 14-19 | Gold and Silver Block Model Interpolation Parameters | 14-42 |

| Table 14-20 | La Luz Underground AgEq Cut-Off Grade Calculation | 14-42 |

| Table 14-21 | La Luz Mineral Resource Estimate at a Cut-off Grade of 150 g/t AgEq (1-5) | 14-43 |

| Table 14-22 | La Luz Sensitivity of Mineral Resource Estimate to AgEq Cut-off | 14-44 |

| Table 14-23 | Average Grade Comparison of Composites with Block Model | 14-45 |

| Table 14-24 | Volumetric Comparison of Block Model with Geometric Wireframes | 14-46 |

| Table 15-1 | Cut-Off Grade Input Parameters | 15-1 |

| Table 15-2 | Cut-Off Grade Calculations | 15-2 |

| Table 15-3 | Dilution by Mining Method | 15-2 |

| Table 15-4 | Terronera and La Luz Probable Mineral Reserve(1-5) | 15-3 |

| Table 16-1 | Required UCS for Various Stope Widths | 16-13 |

| Table 16-2 | Estimated Percentage of Ground Types | 16-15 |

| Table 16-3 | Lateral Waste Development Meter Summary | 16-16 |

| Table 16-4 | Vertical Waste Development Meter Summary | 16-17 |

| Table 16-5 | Lateral Waste Development Schedule by Type and Period (m) | 16-21 |

| Table 16-6 | Production Stopping Schedule by Mining Method | 16-23 |

| Table 16-7 | Development and Production Mining Equipment | 16-25 |

| Table 17-1 | Key Process Design Criteria for the Mill | 17-4 |

| Table 17-2 | Major Equipment at the Terronera Process Mill | 17-5 |

| Table 17-3 | Reagents and Dosage | 17-7 |

| Table 17-4 | 1,600 tpd Power Demand (kW) | 17-8 |

| Table 19-1 | Annual High, Low, and Average London PM Fix for Gold and Silver from 2000 to 2020 | 19-1 |

| Table 19-2 | Market Factors Assumed in Economic Analysis | 19-2 |

| Table 20-1 | Environmental Permits Required for the Terronera Project | 20-3 |

| Table 20-2 | Return Period Storm Event Precipitation | 20-8 |

| Table 21-1 | Capital Cost Estimate Summary | 21-1 |

| Table 21-2 | Estimate Exchange Rates | 21-3 |

| Table 21-3 | Bulk Earthworks Quantities and Rates | 21-4 |

| Table 21-4 | Concrete Quantities & Rates | 21-4 |

| Table 21-5 | Structural Steel Quantities | 21-5 |

| Table 21-6 | Mechanical Equipment & Packages | 21-6 |

| Table 21-7 | Platework | 21-7 |

| Table 21-8 | Pipelines Initial Capex | 21-7 |

| Table 21-9 | Total Estimate Freight | 21-9 |

| Table 21-10 | Field Indirects Detail | 21-9 |

| Table 21-11 | EPCM Summary | 21-10 |

| Table 21-12 | Vendor Support | 21-10 |

| Table 21-13 | Spares | 21-11 |

| Table 21-14 | First Fills | 21-11 |

| Table 21-15 | Contingency Summary | 21-11 |

| Table 21-16 | Growth Summary Direct Initial Costs | 21-12 |

| Table 21-17 | Summary of Sustaining Costs (US$) | 21-13 |

| Table 21-18 | Unit Operating Costs (US$) | 21-13 |

| Table 21-19 | LOM and Unit Operating Costs for Terronera and La Luz Mines (US$) | 21-14 |

104698-02-RX-RPT-001

Rev: A

Date: July 31, 2020

| Table 21-20 | Process Operating Cost Summary (US$) | 21-16 |

| Table 21-21 | 1,600 tpd Power Demand (kW) | 21-17 |

| Table 21-22 | Reagents and Consumables Operating Costs (US$) | 21-17 |

| Table 21-23 | Labour Operating Costs (US$ 000’s) | 21-18 |

| Table 21-24 | Dry Tailings Storage Facility Operating Costs (US$) | 21-19 |

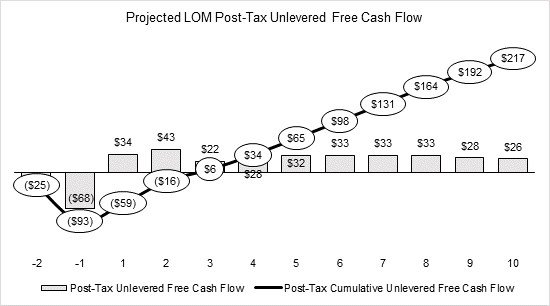

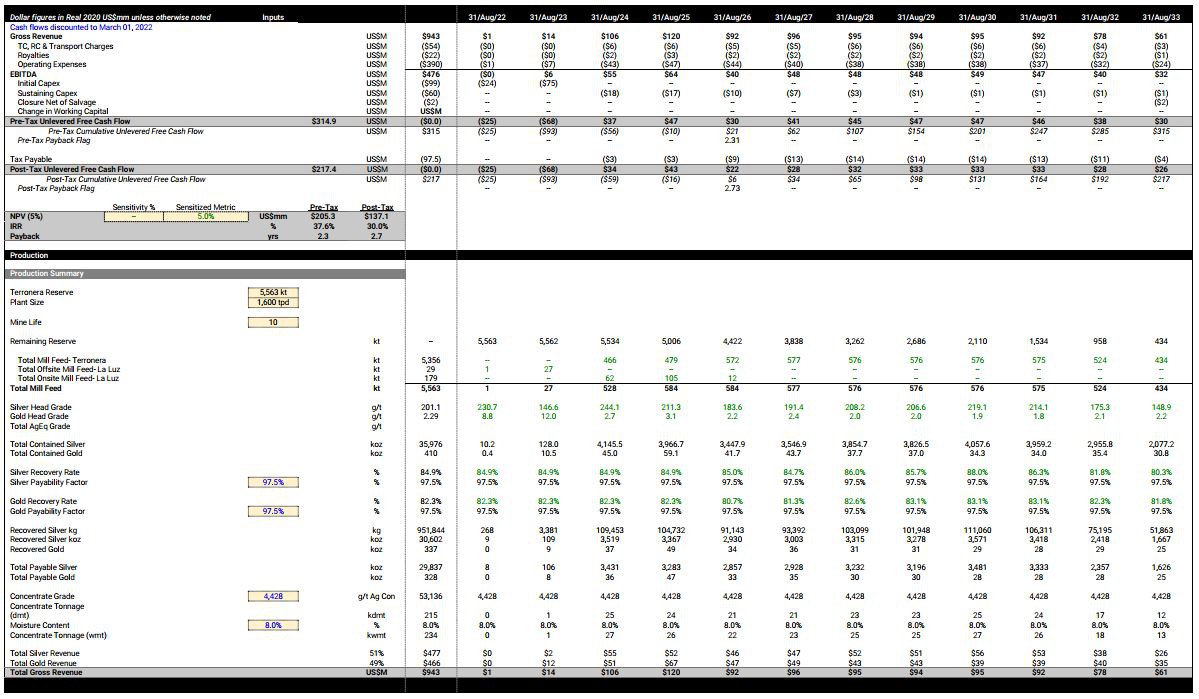

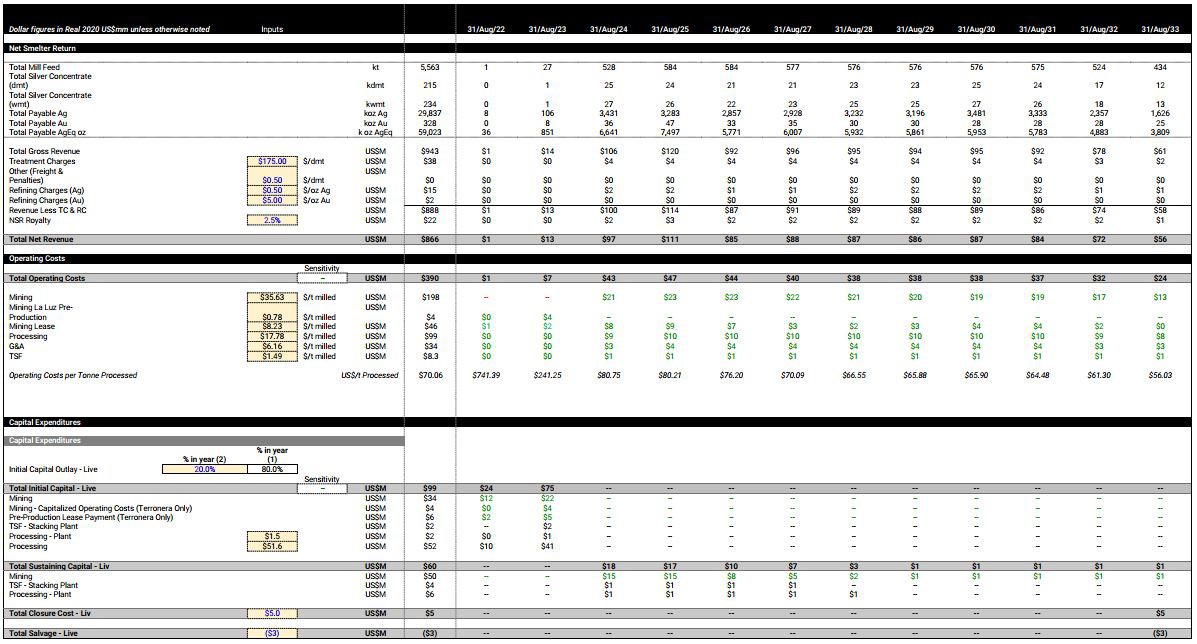

| Table 22-1 | Summary of Project Economics | 22-5 |

| Table 22-2 | Project Cash Flow on an Annualised Basis | 22-7 |

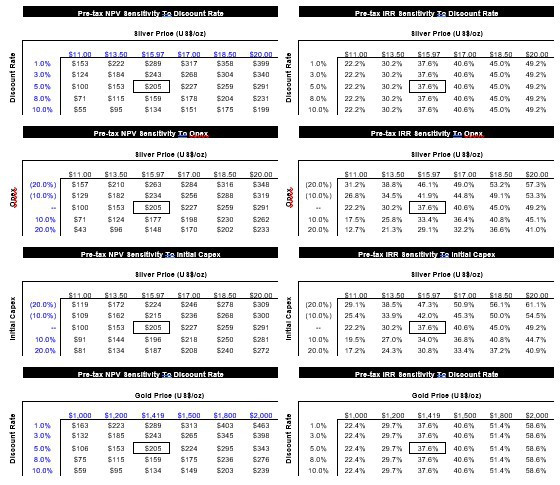

| Table 22-3 | Sensitivity to Metal Prices | 22-9 |

| Table 22-4 | Sensitivity to CAPEX | 22-9 |

| Table 22-5 | Pre-Tax Sensitivity | 22-9 |

| Table 22-6 | Post-Tax Sensitivity | 22-11 |

| Table 25-1 | Terronera Mineral Resource Estimate at a cut-off grade of 150 g/t Ag Eq. (1-6) | 25-2 |

| Table 25-2 | La Luz Mineral Resource Estimate at a cut-off grade of 150 g/t Ag Eq. (1-4) | 25-3 |

| Table 26-1 | Estimated Costs for Completing Work | 26-4 |

104698-02-RX-RPT-001

Rev: A

Date: July 31, 2020

LIST OF FIGURES

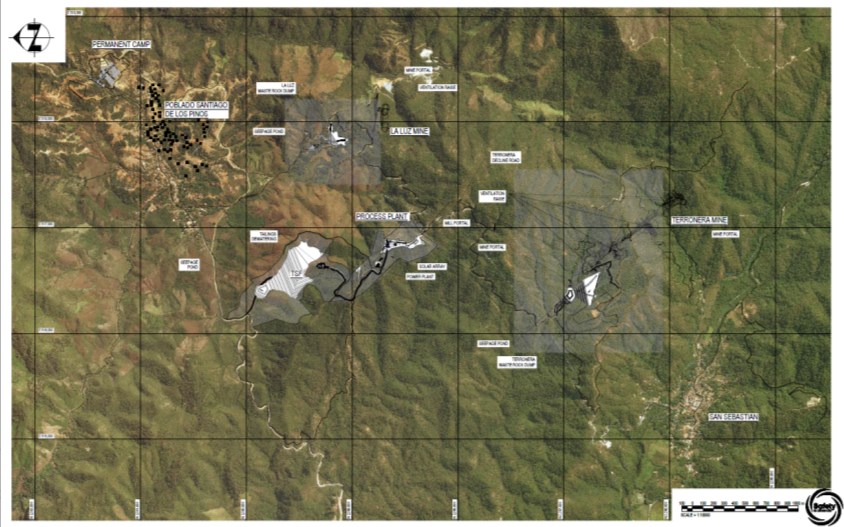

| Figure 1-1 | Terronera Project Location Map | 1-2 |

| Figure 1-2 | View of the Town of San Sebastián from Bufa | 1-3 |

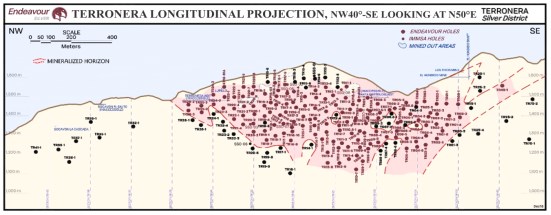

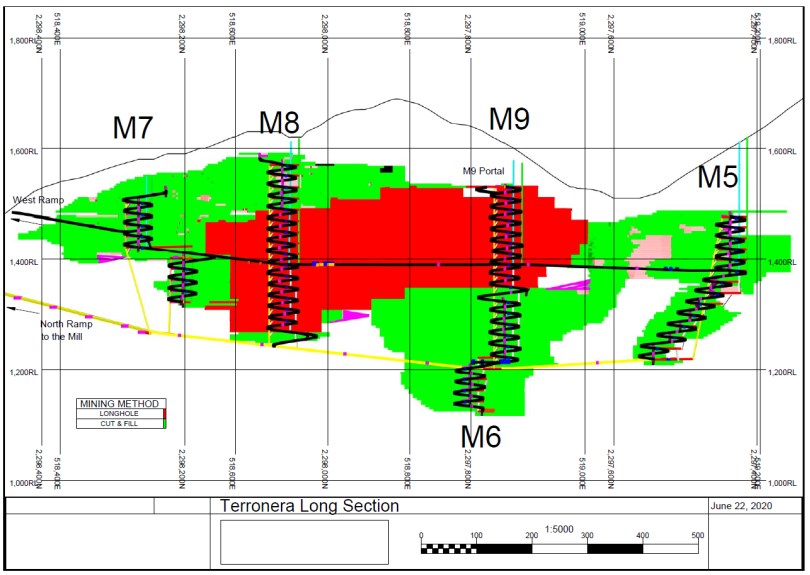

| Figure 1-3 | Terronera Deposit Longitudinal Projection | 1-13 |

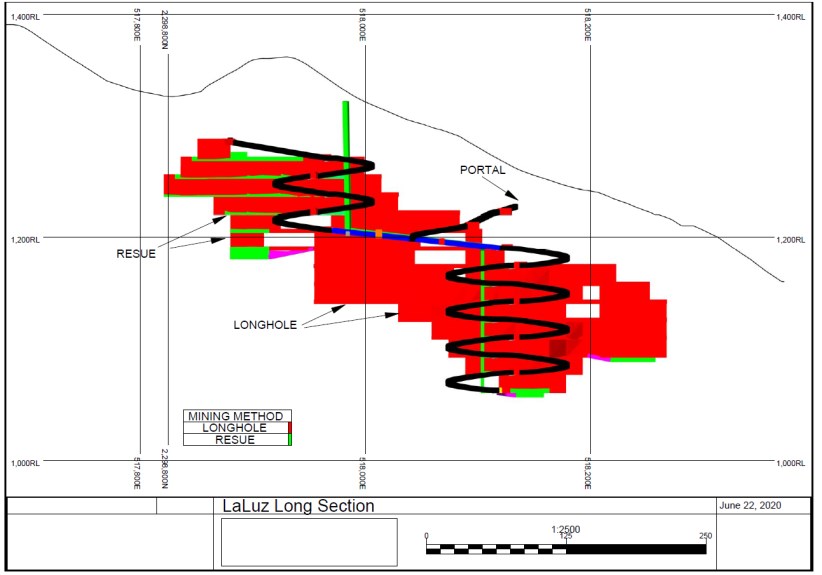

| Figure 1-4 | La Luz Deposit Longitudinal Projection | 1-14 |

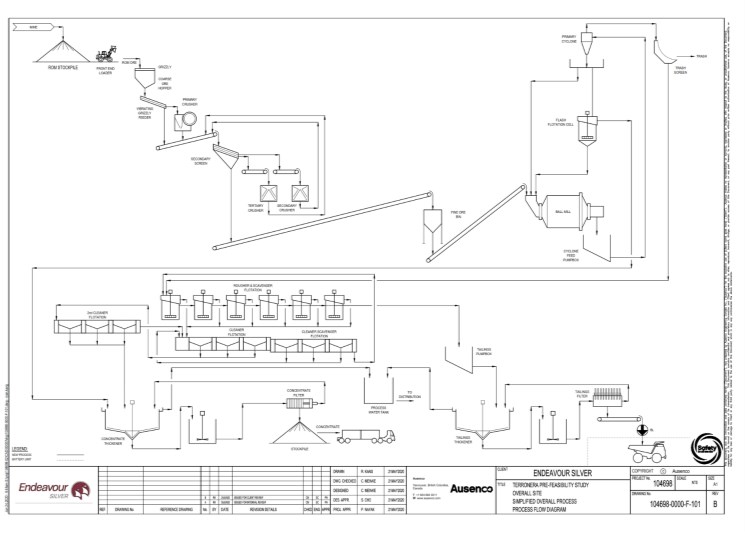

| Figure 1-5 | Overall Process Flow Sheet | 1-17 |

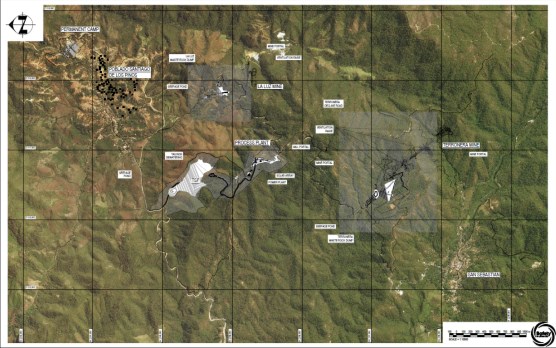

| Figure 1-6 | Map of Proposed Mine Surface Facilities Layout | 1-18 |

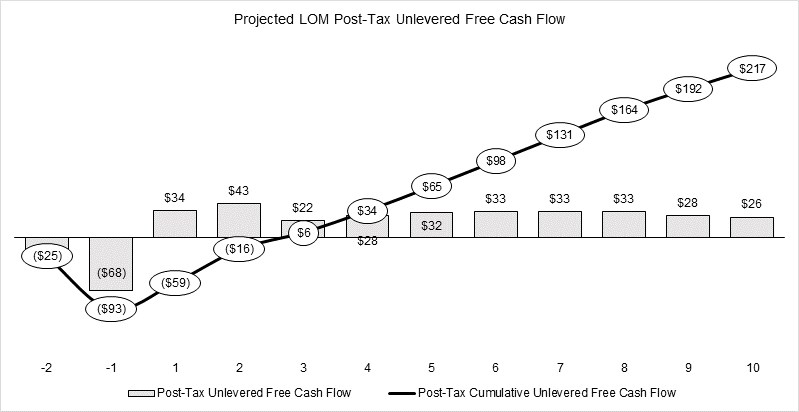

| Figure 1-7 | Project Economics Graph | 1-23 |

| Figure 1-8 | Pre-Tax Sensitivity | 1-25 |

| Figure 1-9 | Post-Tax Sensitivity | 1-26 |

| Figure 4-1 | Terronera Project Location Map | 4-1 |

| Figure 4-2 | Terronera Project Concessions Map | 4-5 |

| Figure 5-1 | View of Topography Surrounding the Town of San Sebastián | 5-2 |

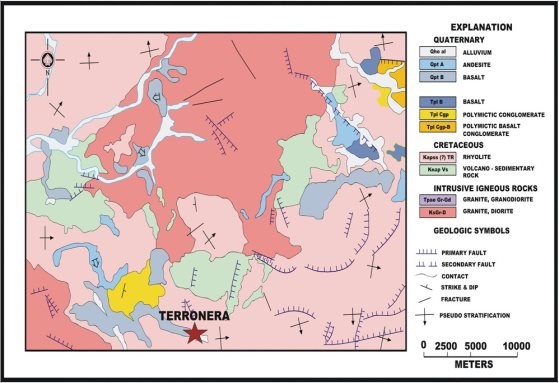

| Figure 7-1 | Geology of the San Sebastián del Oeste Area | 7-2 |

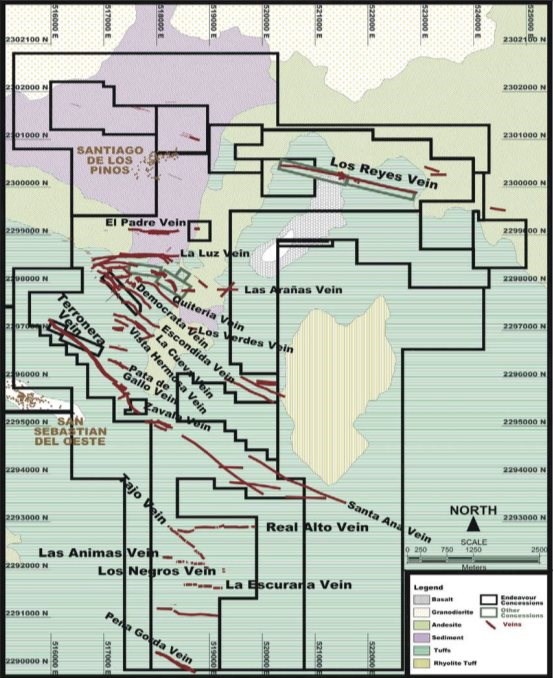

| Figure 7-2 | Terronera Project Geology Showing Mineralized Veins | 7-3 |

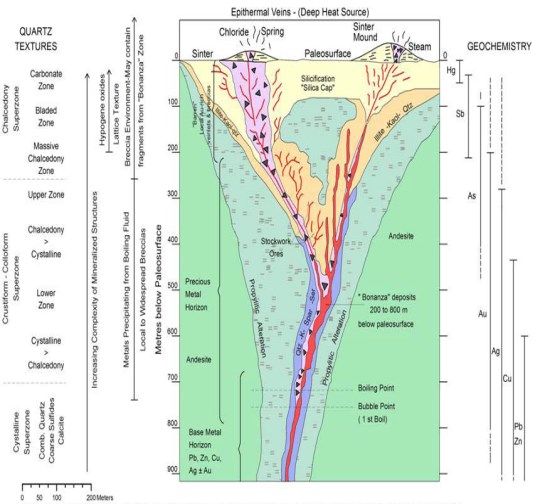

| Figure 8-1 | Alteration and Mineralization Distributions within a Low Sulphidation Epithermal Vein System | 8-3 |

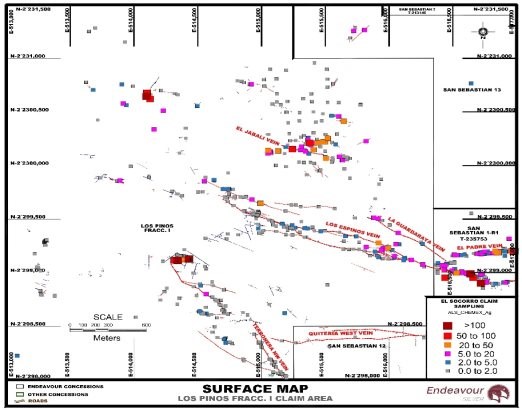

| Figure 9-1 | Silver Results in the Terronera North, Quiteria West, Los Espinos-Guardarraya, and El Jabalí Areas | 9-2 |

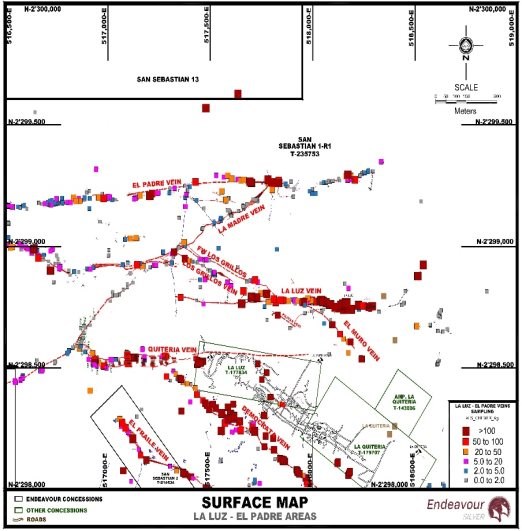

| Figure 9-2 | Silver Results in El Padre, La Madre, La Luz, Quiteria West, Democrata and El Fraile Area | 9-3 |

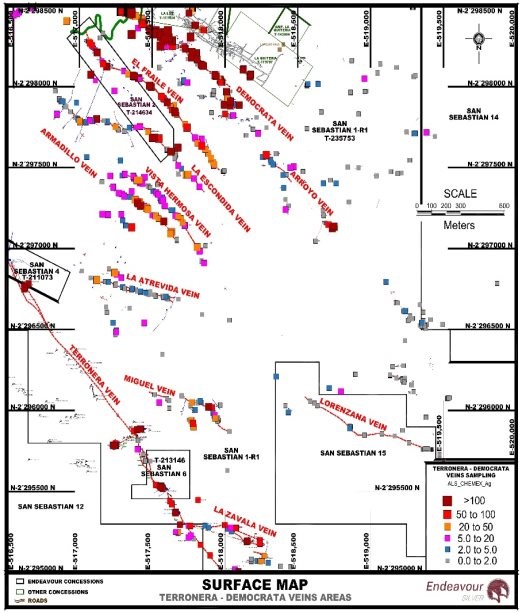

| Figure 9-3 | Silver Results in the Democrata, El Fraile, La Escondida, Vista Hermosa, El Armadillo, La Atrevida, Miguel, Lorenzana, Terronera and Zavala Areas | 9-4 |

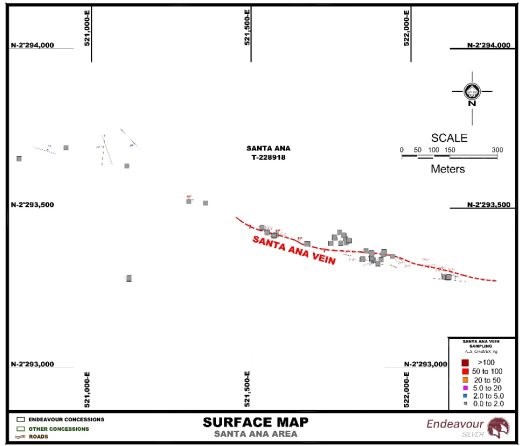

| Figure 9-4 | Silver Results in the Santa Ana Area | 9-5 |

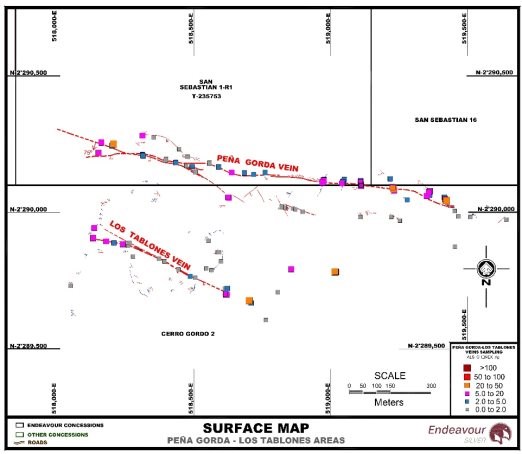

| Figure 9-5 | Silver Results in the Peña Gorda and Los Tablones | 9-6 |

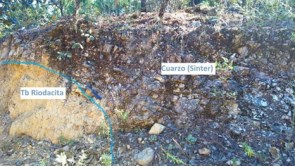

| Figure 9-6 | Terronera NW Vein Outcrop Photographs Showing Massive, White Quartz with Values of 1.0 g/t Ag | 9-7 |

| Figure 9-7 | Terronera NW Vein Photograph Showing the Vertical Displacement of the Vein by Faulting | 9-7 |

| Figure 9-8 | Los Espinos Vein Photographs with FeO, MnO and Some Sporadic Oxidized Pyrite | 9-8 |

| Figure 9-9 | Los Espinos Vein Photograph with FeO, MnO and Sporadic Oxidized Pyrite | 9-9 |

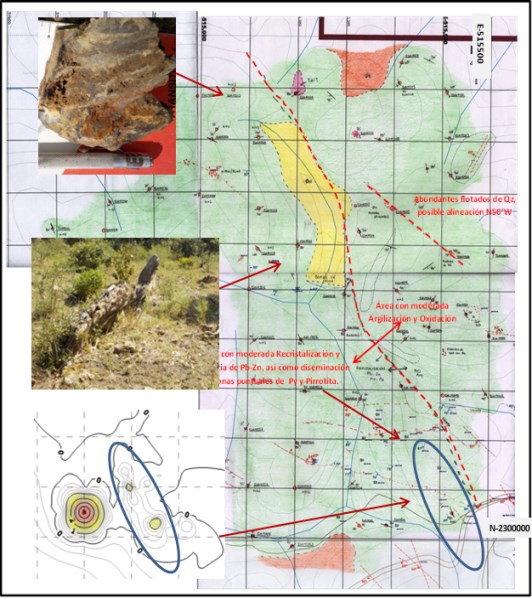

| Figure 9-10 | El Jabalí Surface Map and Photographs Showing the General Zone Trend | 9-10 |

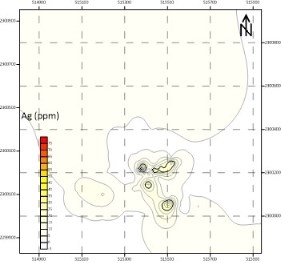

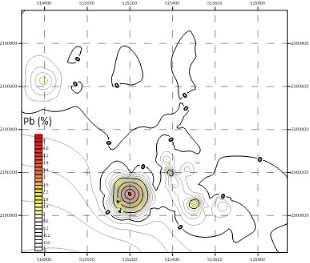

| Figure 9-11 | Isovalue Diagrams Showing the Trends of the Silver and Lead Anomalies with the Northwest Trend | 9-11 |

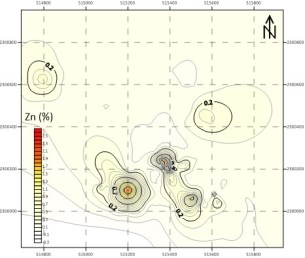

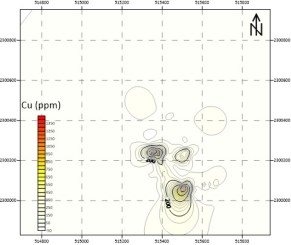

| Figure 9-12 | Isovalue Diagrams Showing Trends of Zinc and Copper Anomalies with the Northwest Trend | 9-11 |

| Figure 9-13 | El Fraile Vein Photographs Looking Northwest | 9-12 |

| Figure 9-14 | Mine Working Over the Vista Hermosa Vein, Photographs with White and Crystalline Quartz, 0.90 m Wide Vein | 9-13 |

| Figure 9-15 | El Ñero Mine Photograph 1 m Wide Vein | 9-14 |

| Figure 9-16 | El Armadillo Vein Photographs with Sulphides Inside the Vein | 9-15 |

| Figure 9-17 | Quartz Veinlet Photographs 10 cm Wide Veinlet, with Moderate FeO, Weak Selective Argillization, Small Rhyolite Clasts | 9-15 |

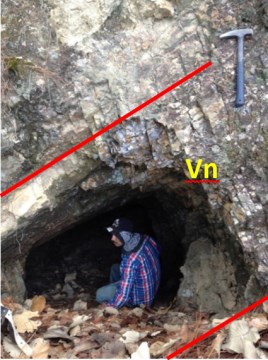

| Figure 9-18 | Quartz Vein Photographs | 9-16 |

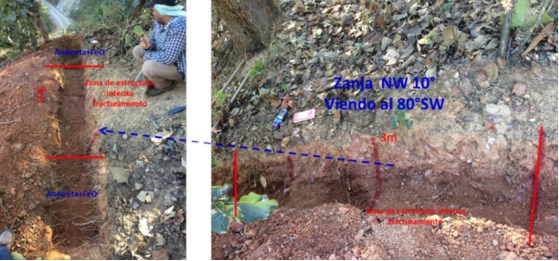

| Figure 9-19 | Trench Photographs | 9-17 |

| Figure 9-20 | Panoramic View of the Santana Vein Trace with Evidence of Quartz Veinlets and FeO | 9-17 |

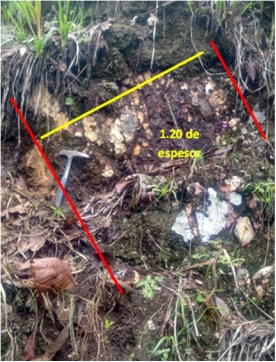

| Figure 9-21 | Peña Gorda Vein Photographs with Outcrops for Approximately 1.4 km | 9-18 |

| Figure 9-22 | Outcrop of the Los Tablones Vein (Quartz Vein) | 9-19 |

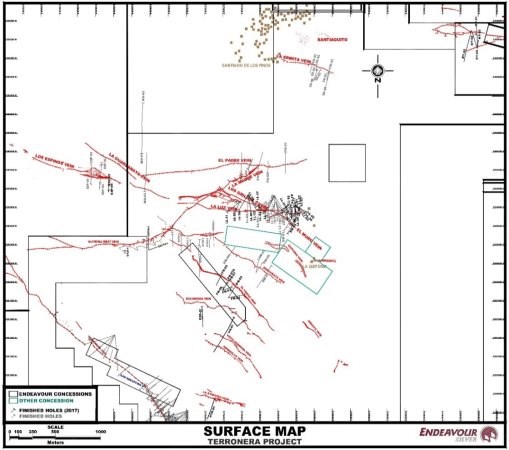

| Figure 10-1 | Terronera Surface Map Showing 2017 Completed Drill Holes | 10-24 |

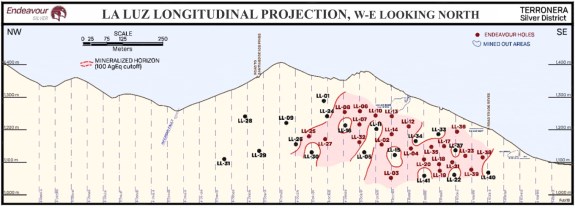

| Figure 10-2 | Drill Intersections – La Luz Vein Longitudinal Projection 2018 Drilling Program | 10-28 |

| Figure 10-3 | Terronera Surface Map Showing Completed 2018 Drill Holes | 10-31 |

104698-02-RX-RPT-001

Rev: A

Date: July 31, 2020

| Figure 10-4 | 2018 Drill Intersections – Terronera Vein Longitudinal Projection | 10-38 |

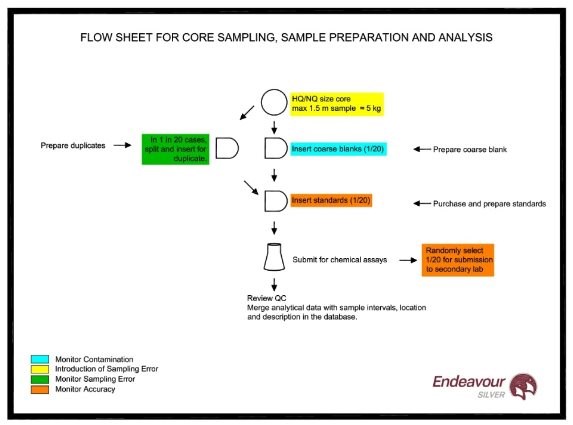

| Figure 11-1 | Flowsheet for Core Sampling, Preparation and Analysis | 11-3 |

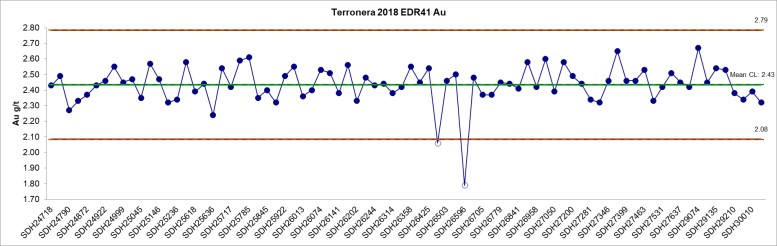

| Figure 11-2 | Control Chart for Gold Assays from the CRM Sample EDR-41 | 11-6 |

| Figure 11-3 | Control Chart for Silver Assays from the CRM Sample EDR-41 | 11-6 |

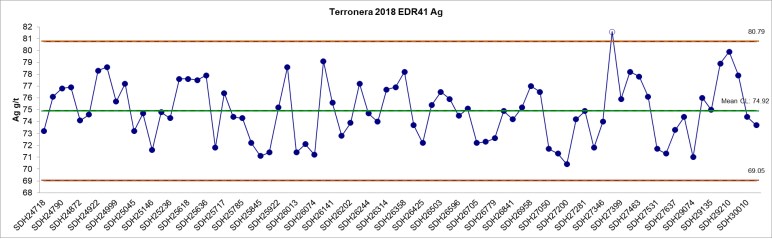

| Figure 11-4 | Control Chart for Gold Assays from the CRM Sample EDR-44 | 11-7 |

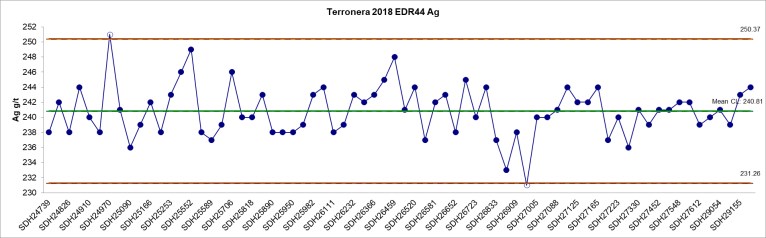

| Figure 11-5 | Control Chart for Silver Assays from the CRM Sample EDR-44 | 11-7 |

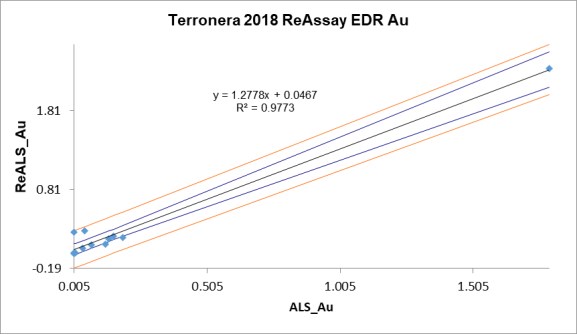

| Figure 11-6 | Performance of Re-assayed ALS Samples for Gold | 11-9 |

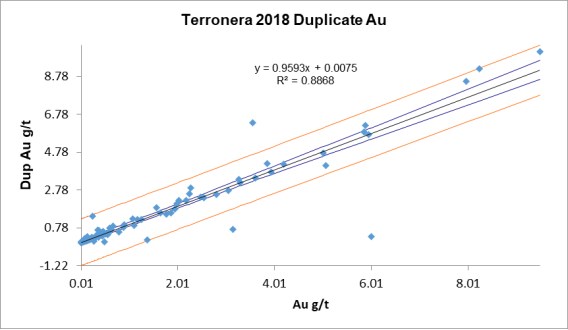

| Figure 11-7 | Performance of Crushed Field Duplicates for Gold | 11-10 |

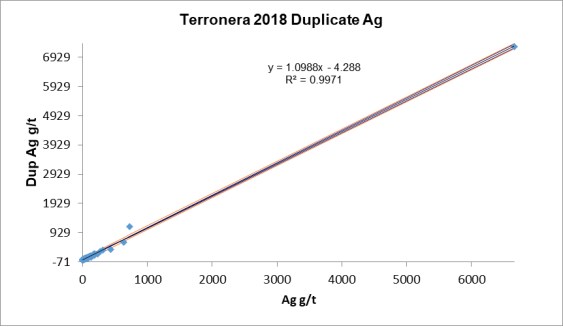

| Figure 11-8 | Performance of Crushed Field Duplicates for Silver | 11-10 |

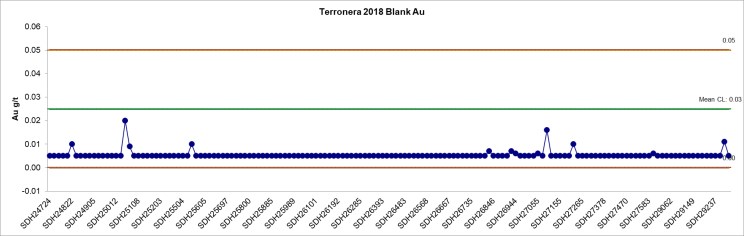

| Figure 11-9 | Control Chart for Gold Blank Samples | 11-12 |

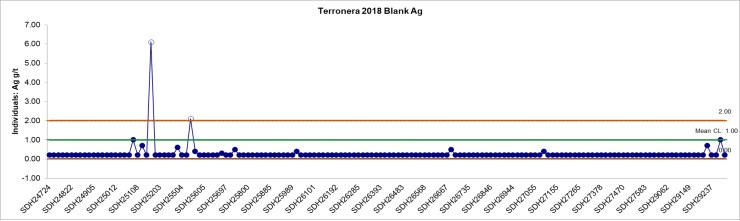

| Figure 11-10 | Control Chart for Silver Blank Samples | 11-12 |

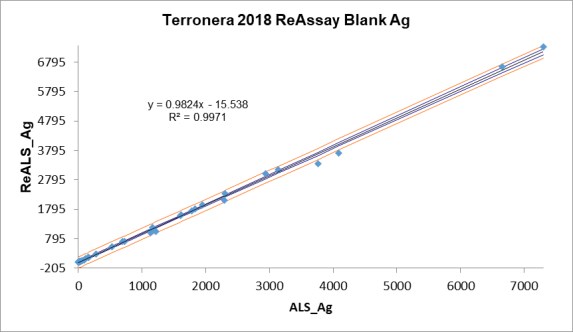

| Figure 11-11 | Performance of Re-assayed ALS Samples for Silver | 11-15 |

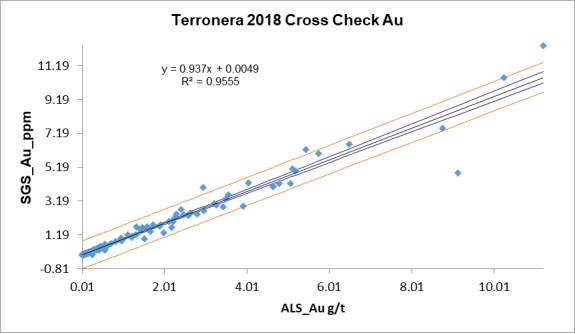

| Figure 11-12 | Performance of SGS Durango Check Assays for Gold | 11-18 |

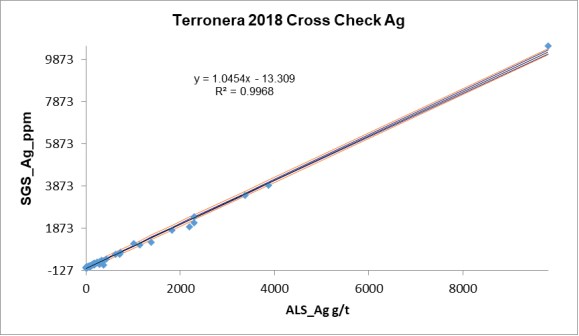

| Figure 11-13 | Performance of SGS Durango Check Assays for Silver | 11-18 |

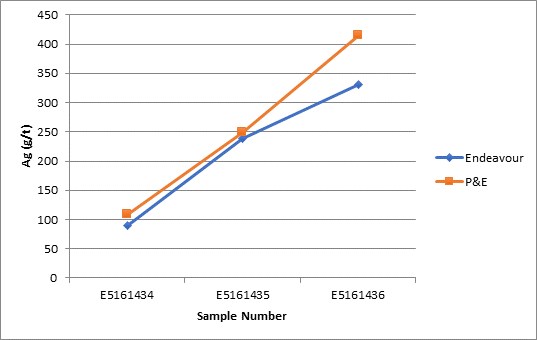

| Figure 12-1 | Results of La Luz Verification Sampling for Gold by P&E – January 2018 | 12-2 |

| Figure 12-2 | Results of La Luz Verification Sampling for Silver by P&E – January 2018 | 12-2 |

| Figure 12-3 | Results of Terronera Verification Sampling for Gold by P&E – January 2018 | 12-3 |

| Figure 12-4 | Results of Terronera Verification Sampling for Silver by P&E – January 2018 | 12-3 |

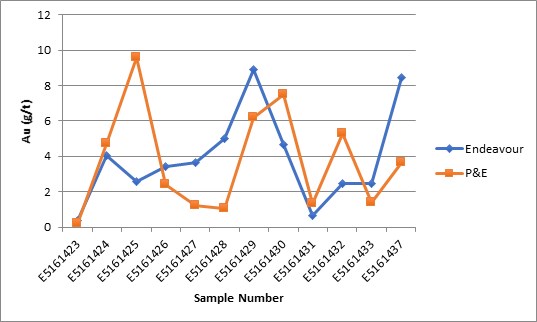

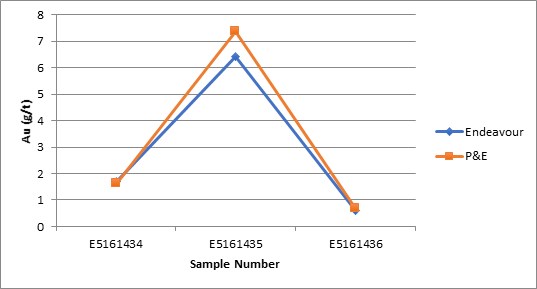

| Figure 12-5 | Results of Terronera Verification Sampling for Gold by P&E – October 2018 | 12-4 |

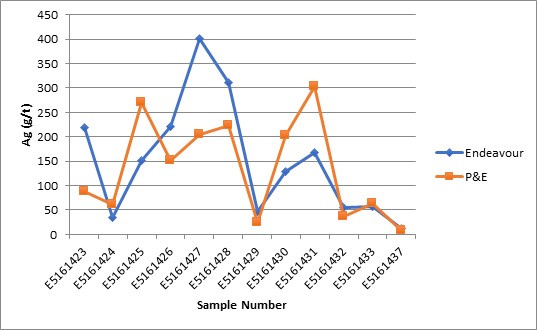

| Figure 12-6 | Results of Terronera Verification Sampling for Silver by P&E – October 2018 | 12-4 |

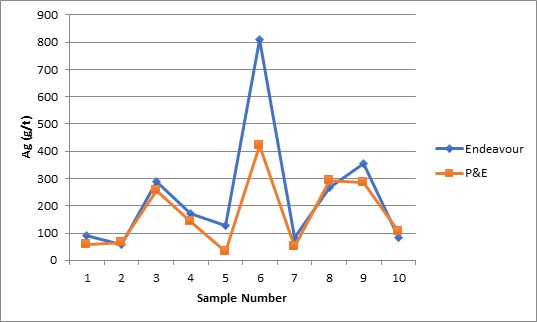

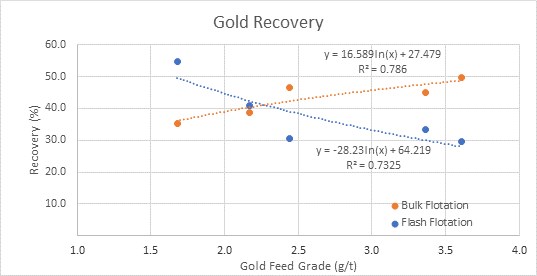

| Figure 13-1 | High- and Low-grade Grind Size vs 2020 Metallurgical Testwork Recovery | 13-5 |

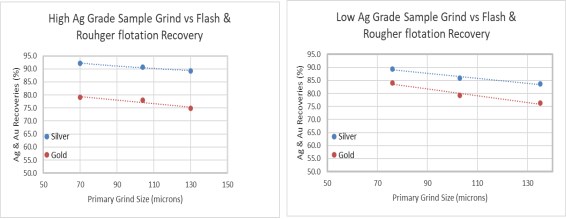

| Figure 13-2 | Silver Recovery Model | 13-6 |

| Figure 13-3 | Gold Recovery Model | 13-7 |

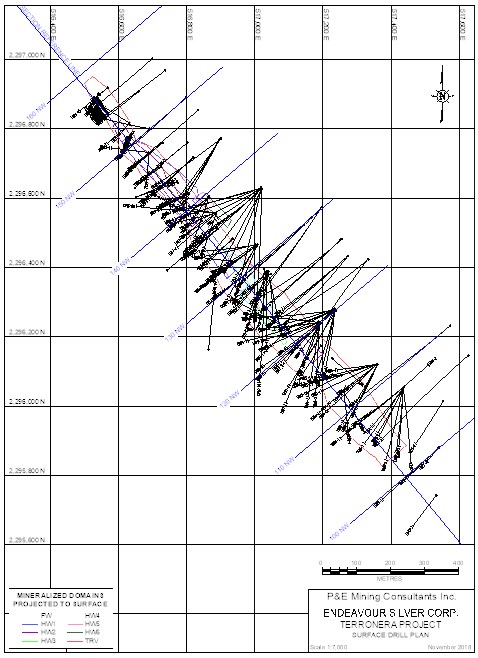

| Figure 14-1 | Terronera Surface Drill Hole Plan | 14-2 |

| Figure 14-2 | Terronera Deposit 3-D Domains and Wireframes | 14-4 |

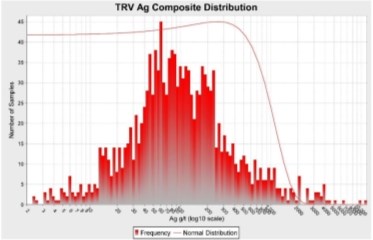

| Figure 14-3 | Terronera TRV Ag Composite Distribution | 14-7 |

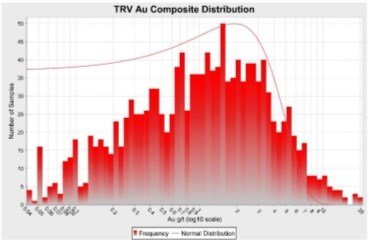

| Figure 14-4 | Terronera TRV Au Composite Distribution | 14-7 |

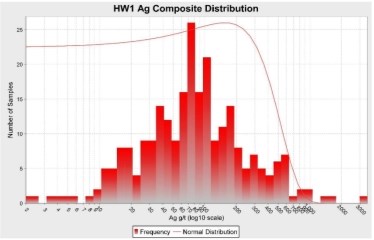

| Figure 14-5 | Terronera HW1 Ag Composite Distribution | 14-7 |

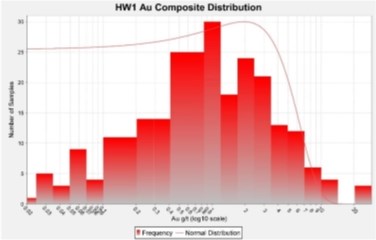

| Figure 14-6 | Terronera HW1 Au Composite Distribution | 14-8 |

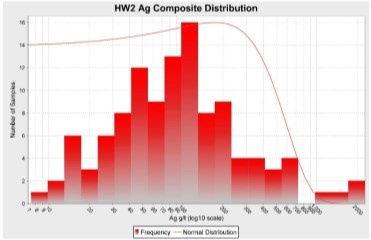

| Figure 14-7 | Terronera HW2 Ag Composite Distribution | 14-8 |

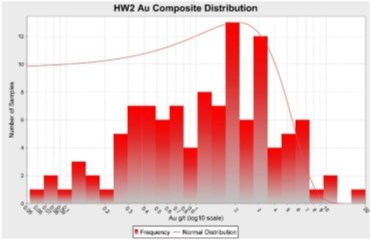

| Figure 14-8 | Terronera HW2 Au Composite Distribution | 14-8 |

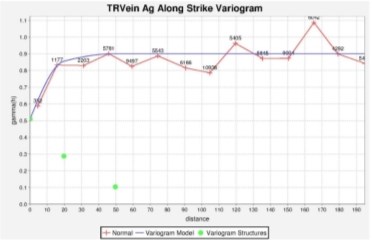

| Figure 14-9 | Terronera TR Vein Ag Along Strike Variogram | 14-11 |

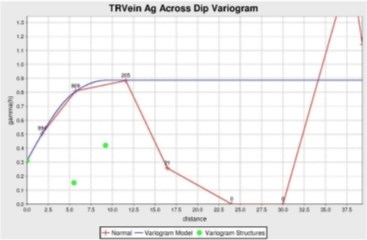

| Figure 14-10 | Terronera TR Vein Ag Across Dip Variogram | 14-11 |

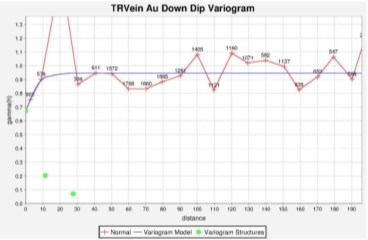

| Figure 14-11 | Terronera TR Vein Au Along Strike Variogram | 14-12 |

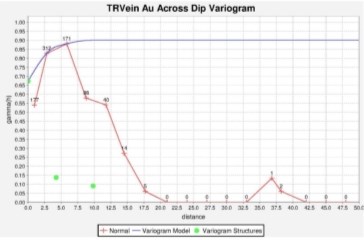

| Figure 14-12 | Terronera TR Vein Au Down Dip Variogram | 14-12 |

| Figure 14-13 | Terronera TR Vein Au Across Dip Variogram | 14-12 |

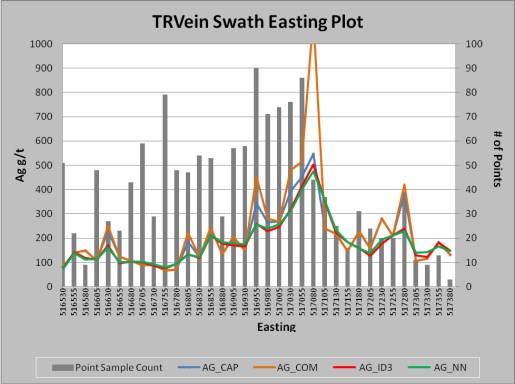

| Figure 14-14 | Terronera Silver Grade Swath Easting Plot | 14-18 |

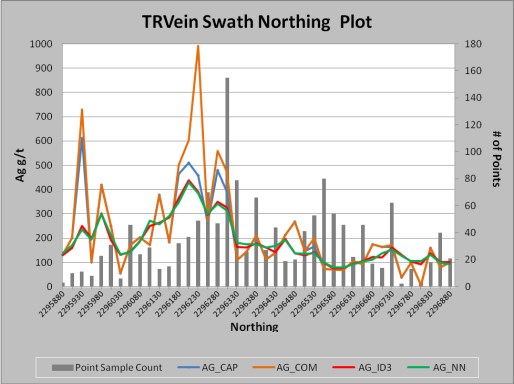

| Figure 14-15 | Silver Grade Swath Northing Plot | 14-18 |

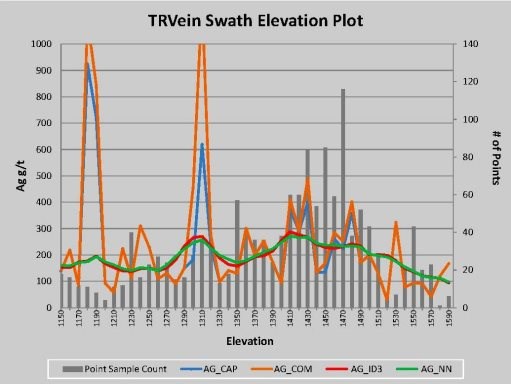

| Figure 14-16 | Silver Grade Swath Elevation Plot | 14-19 |

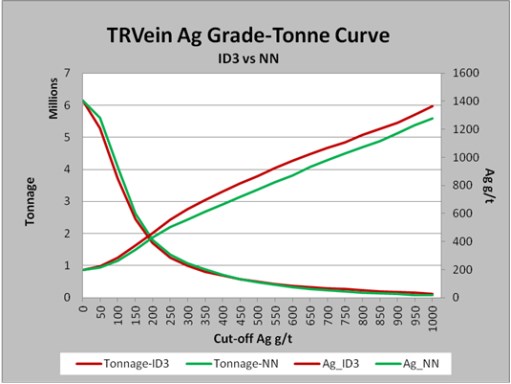

| Figure 14-17 | Silver Grade-Tonne Curve of Terronera Vein by ID3 and NN Interpolation | 14-20 |

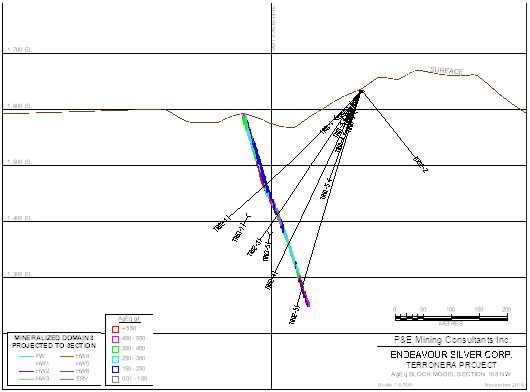

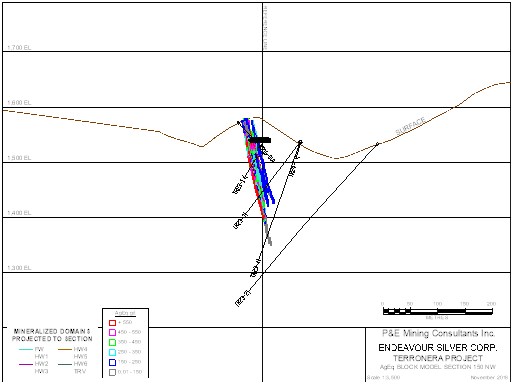

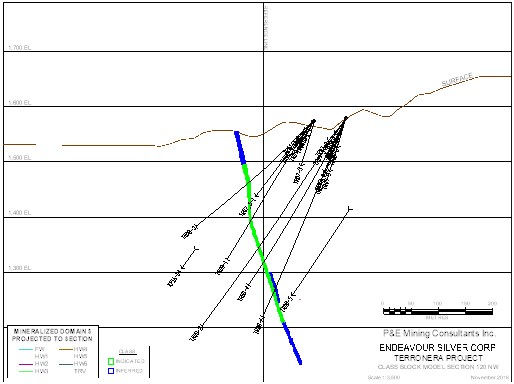

| Figure 14-18 | Silver Equivalent Block Model Section 108 NW, Terronera Deposit | 14-21 |

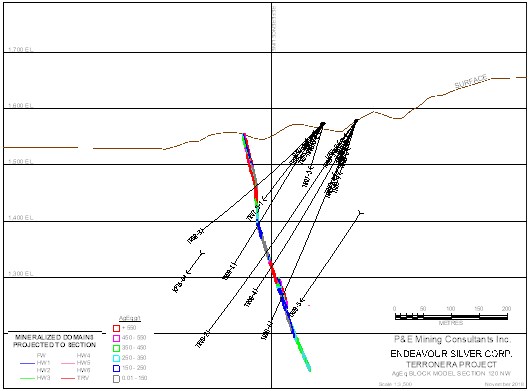

| Figure 14-19 | Silver Equivalent Block Model Section 120 NW, Terronera Deposit | 14-21 |

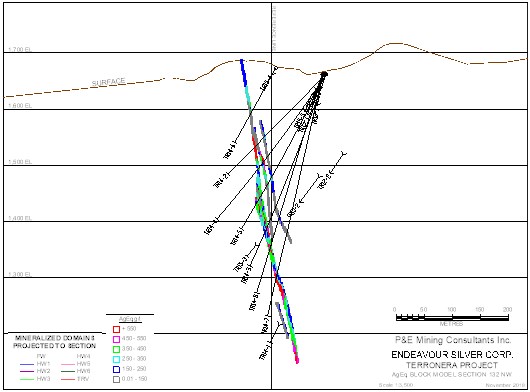

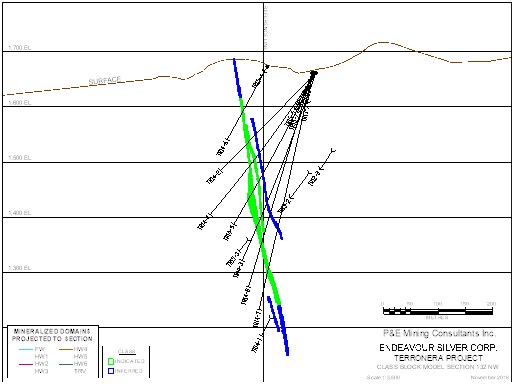

| Figure 14-20 | Silver Equivalent Block Model Section 132 NW, Terronera Deposit | 14-22 |

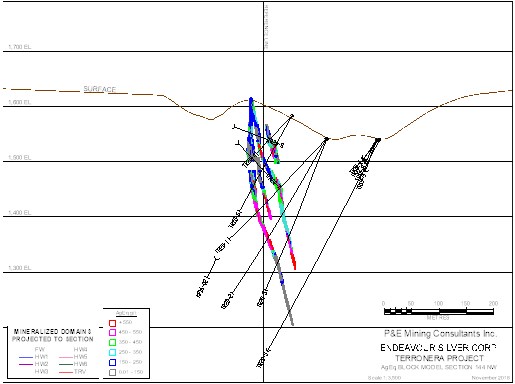

| Figure 14-21 | Silver Equivalent Block Model Section 144 NW, Terronera Deposit | 14-22 |

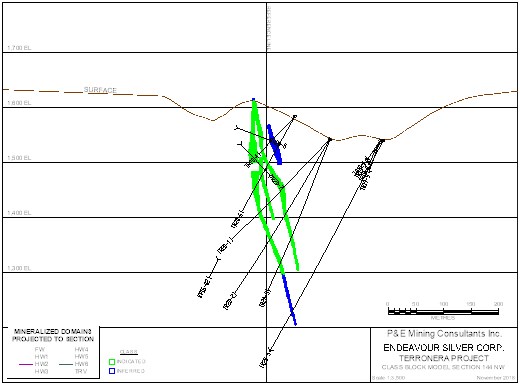

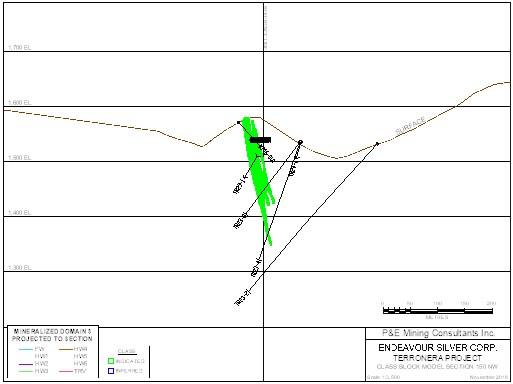

| Figure 14-22 | Silver Equivalent Block Model Section 150 NW, Terronera Deposit | 14-23 |

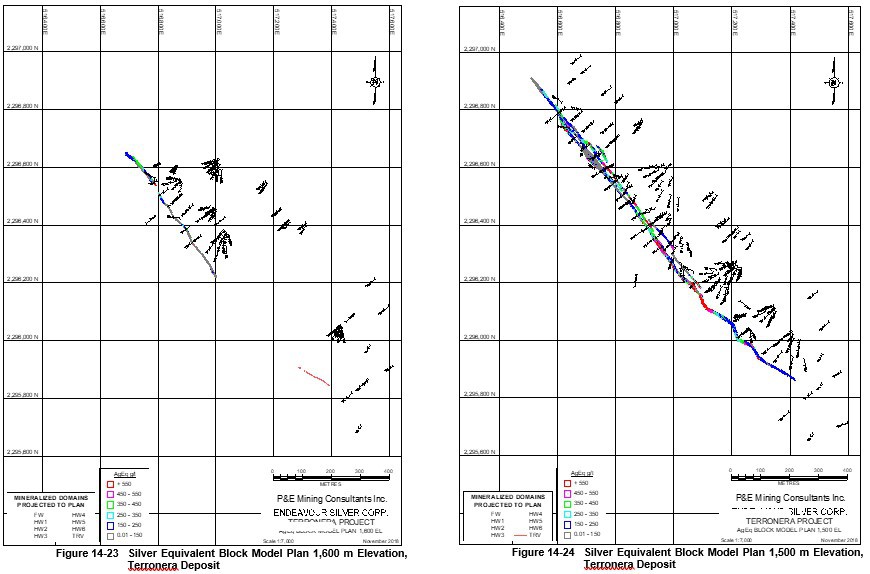

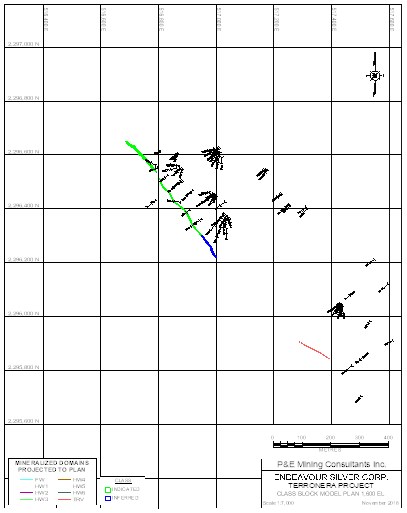

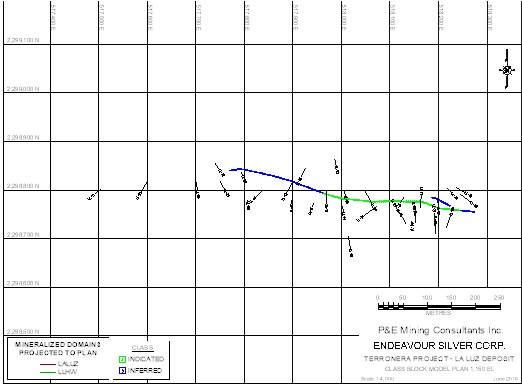

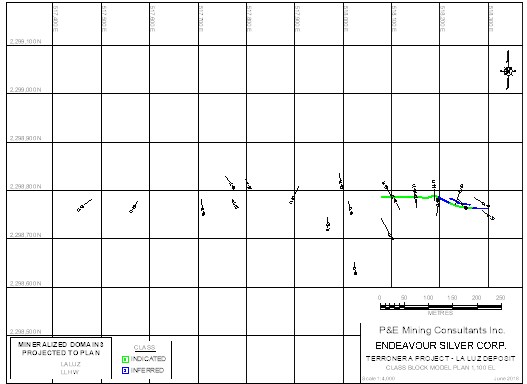

| Figure 14-23 | Silver Equivalent Block Model Plan 1,600 m Elevation, Terronera Deposit | 14-24 |

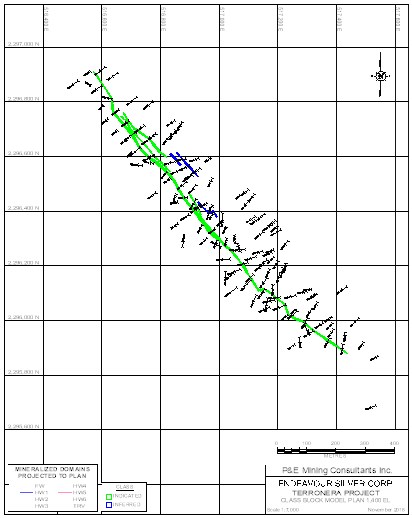

| Figure 14-24 | Silver Equivalent Block Model Plan 1,500 m Elevation, Terronera Deposit | 14-24 |

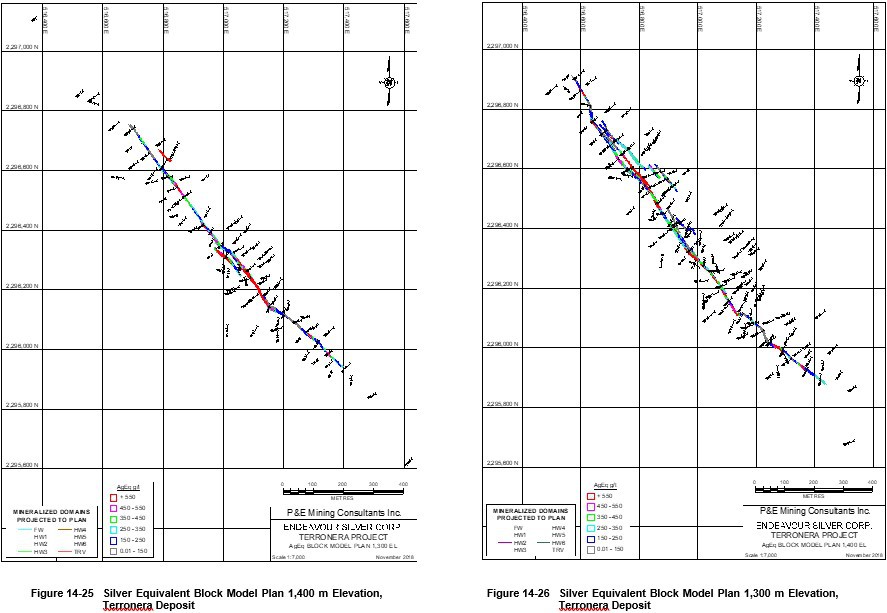

| Figure 14-25 | Silver Equivalent Block Model Plan 1,400 m Elevation, Terronera Deposit | 14-25 |

| Figure 14-26 | Silver Equivalent Block Model Plan 1,300 m Elevation, Terronera Deposit | 14-25 |

| Figure 14-27 | Classification Block Model Vertical Cross Section 108 NW, Terronera Deposit | 14-26 |

| Figure 14-28 | Classification Block Model Vertical Cross Section 120 NW, Terronera Deposit | 14-27 |

| Figure 14-29 | Classification Block Model Vertical Cross Section 132 NW, Terronera Deposit | 14-27 |

| Figure 14-30 | Classification Block Model Vertical Cross Section 144 NW, Terronera Deposit | 14-28 |

104698-02-RX-RPT-001

Rev: A

Date: July 31, 2020

| Figure 14-31 | Classification Block Model Vertical Cross Section 150 NW, Terronera Deposit | 14-28 |

| Figure 14-32 | Classification Block Model Plan 1,600 m Elevation, Terronera Deposit | 14-29 |

| Figure 14-33 | Classification Block Model Plan 1,500 m Elevation, Terronera Deposit | 14-29 |

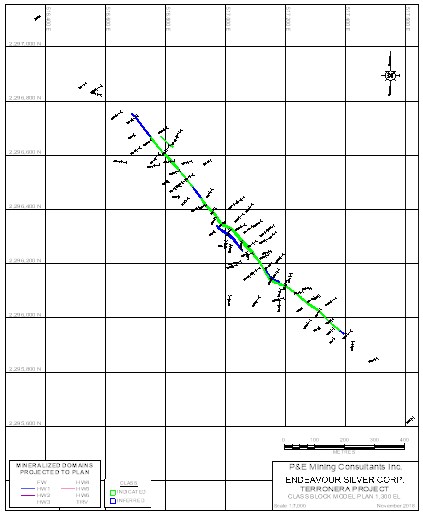

| Figure 14-34 | Classification Block Model Plan 1,400 m Elevation, Terronera Deposit | 14-30 |

| Figure 14-35 | Classification Block Model Plan 1,300 m Elevation, Terronera Deposit | 14-30 |

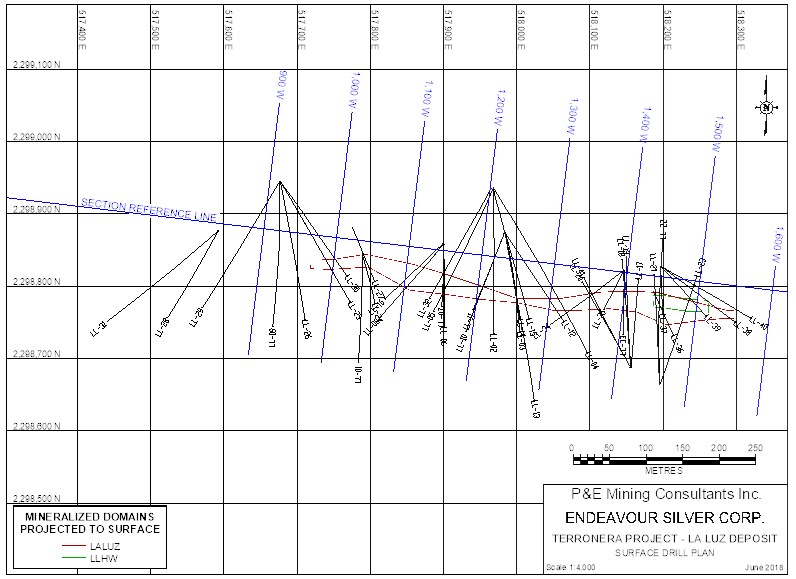

| Figure 14-36 | La Luz Surface Drill Hole Plan | 14-33 |

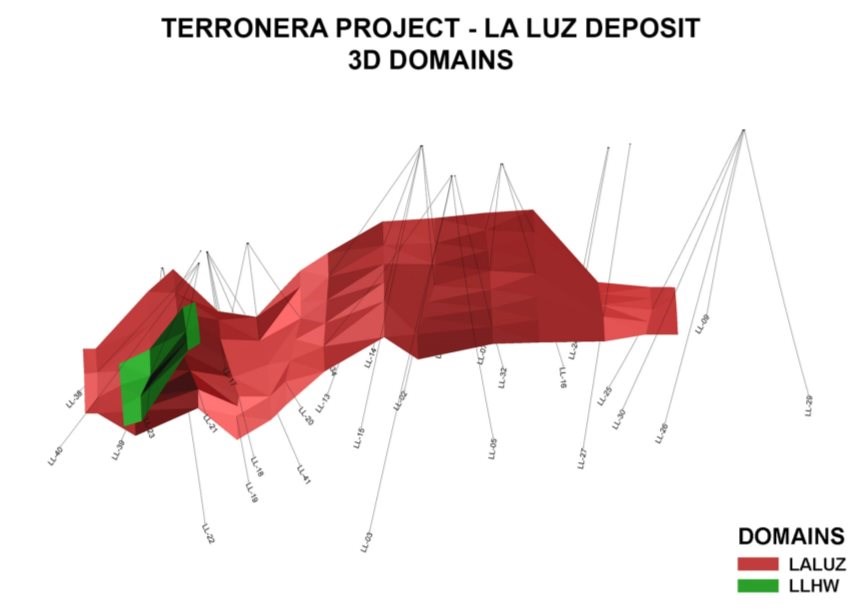

| Figure 14-37 | La Luz Deposit 3-D Domains and Wireframes | 14-35 |

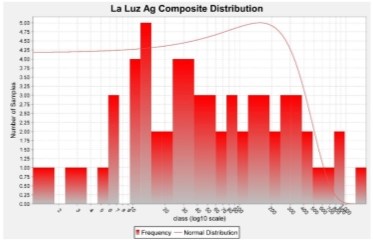

| Figure 14-38 | La Luz Ag Composite Distribution | 14-37 |

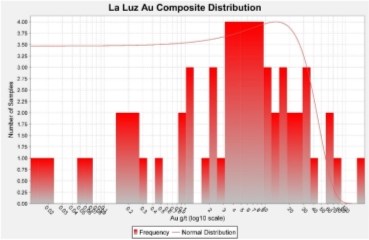

| Figure 14-39 | La Luz Au Composite Distribution | 14-38 |

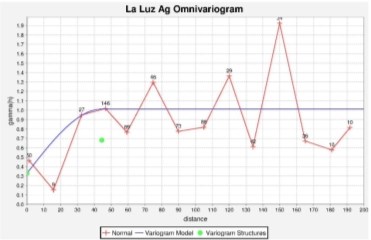

| Figure 14-40 | La Luz Ag Omnivariogram | 14-39 |

| Figure 14-41 | La Luz Ag Along Strike Variogram | 14-39 |

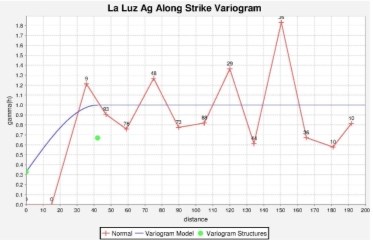

| Figure 14-42 | La Luz Ag Down Dip Variogram | 14-39 |

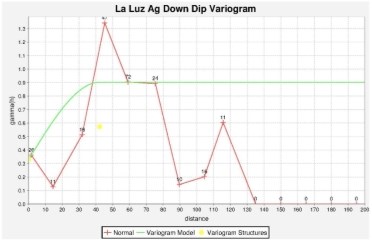

| Figure 14-43 | La Luz Au Omnivariogram | 14-40 |

| Figure 14-44 | La Luz Au Along Strike Variogram | 14-40 |

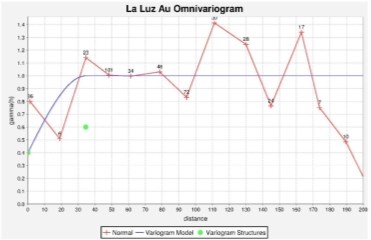

| Figure 14-45 | La Luz Au Down Dip Variogram | 14-40 |

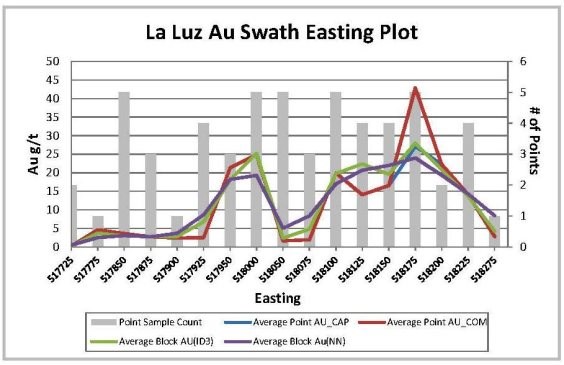

| Figure 14-46 | La Luz Silver Grade Swath Easting Plot | 14-46 |

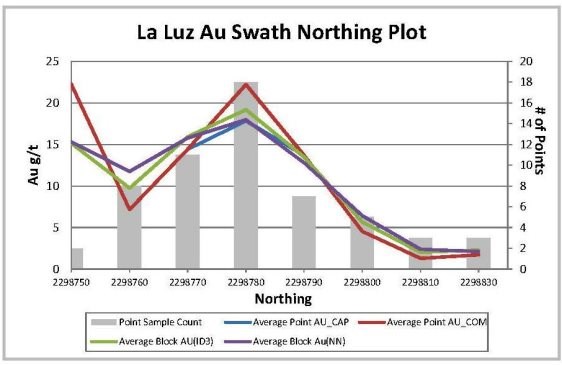

| Figure 14-47 | Silver Grade Swath Northing Plot | 14-47 |

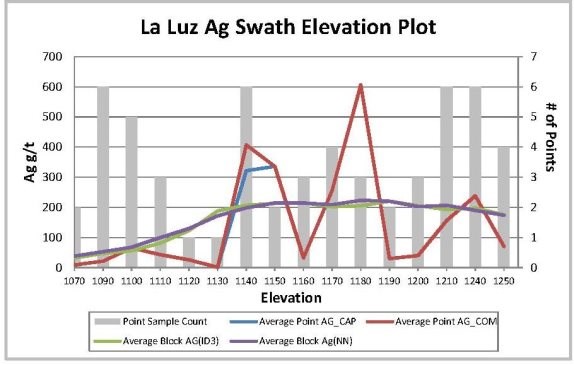

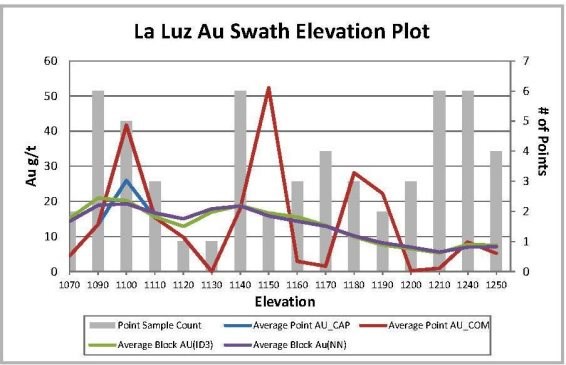

| Figure 14-48 | Silver Grade Swath Elevation Plot | 14-47 |

| Figure 14-49 | Gold Grade Swath Easting Plot | 14-48 |

| Figure 14-50 | Gold Grade Swath Northing Plot | 14-48 |

| Figure 14-51 | Gold Grade Swath Elevation Plot | 14-49 |

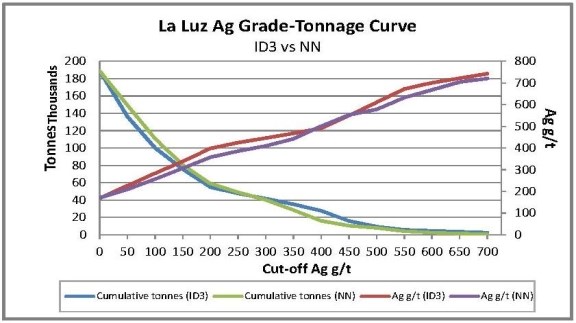

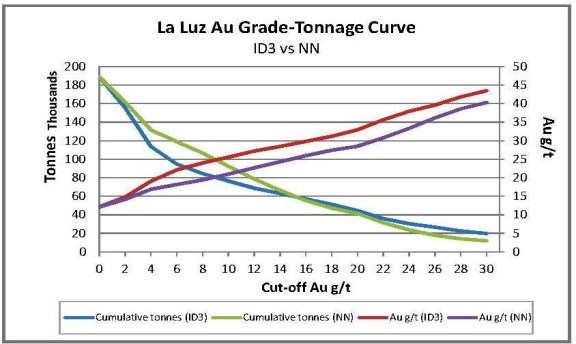

| Figure 14-52 | Silver Grade and Tonnage Comparisons for ID3 and NN Interpolation | 14-49 |

| Figure 14-53 | Gold Grade and Tonnage Comparisons for ID3 and NN Interpolation | 14-50 |

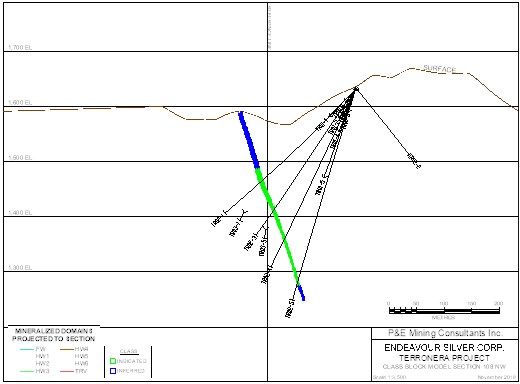

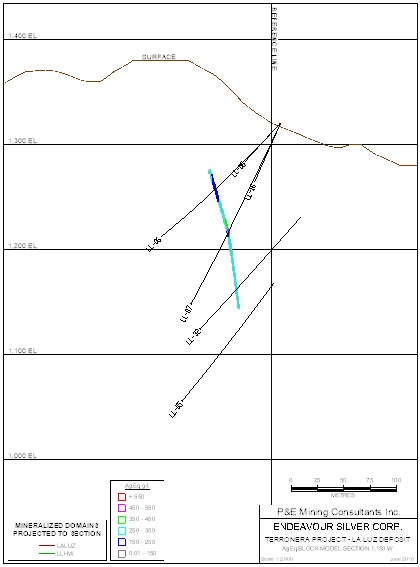

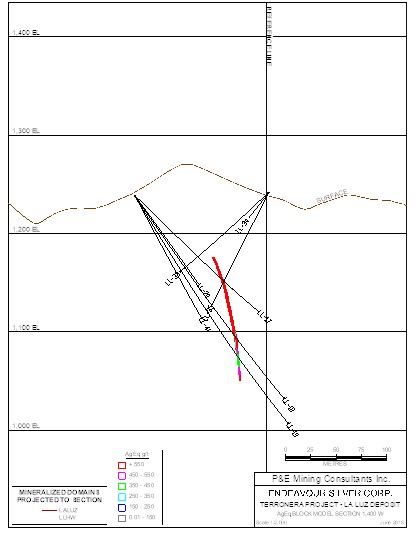

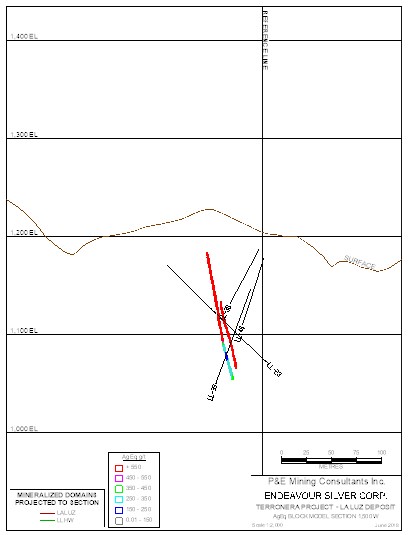

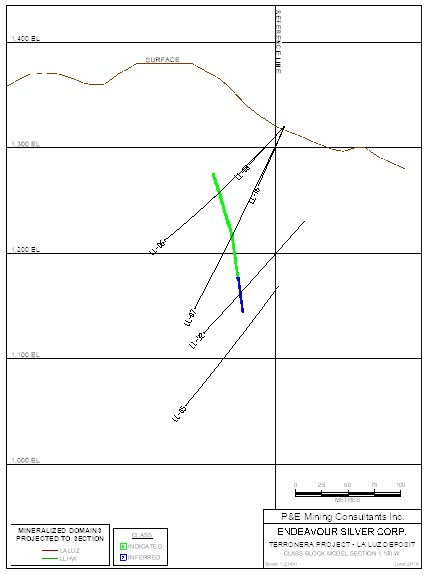

| Figure 14-54 | Silver Equivalent Block Model Section 1,150 W, La Luz Deposit | 14-51 |

| Figure 14-55 | Silver Equivalent Block Model Section 1,400 W, La Luz Deposit | 14-52 |

| Figure 14-56 | Silver Equivalent Block Model Section 1,500 W, La Luz Deposit | 14-52 |

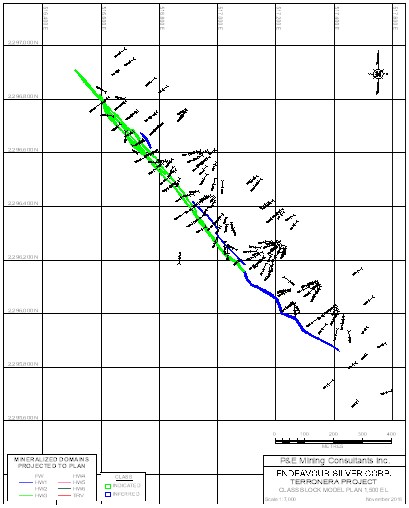

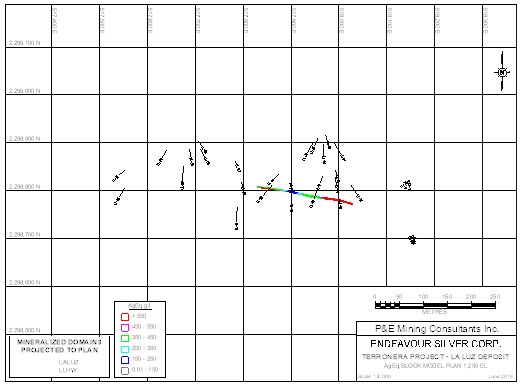

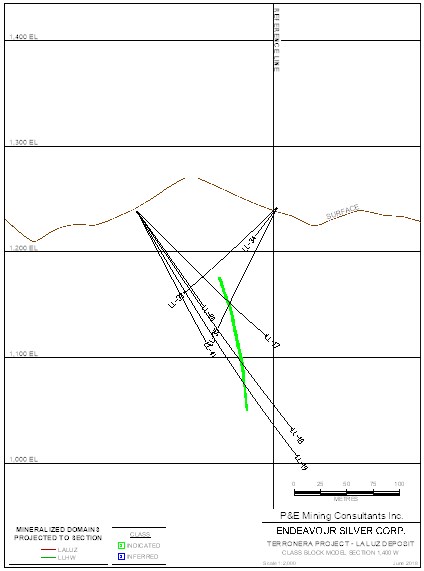

| Figure 14-57 | Silver Equivalent Block Model Plan 1,250 m Elevation, La Luz Deposit | 14-53 |

| Figure 14-58 | Silver Equivalent Block Model Plan 1,150 m Elevation, La Luz Deposit | 14-53 |

| Figure 14-59 | Silver Equivalent Block Model Plan 1,100 m Elevation, La Luz Deposit | 14-54 |

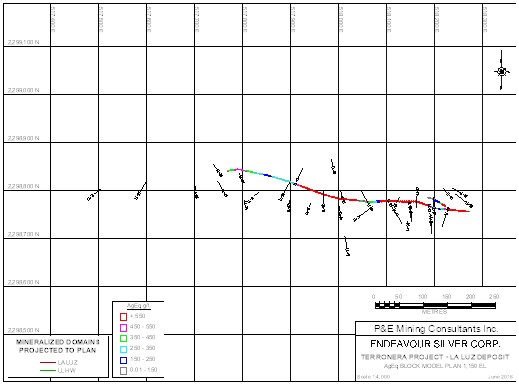

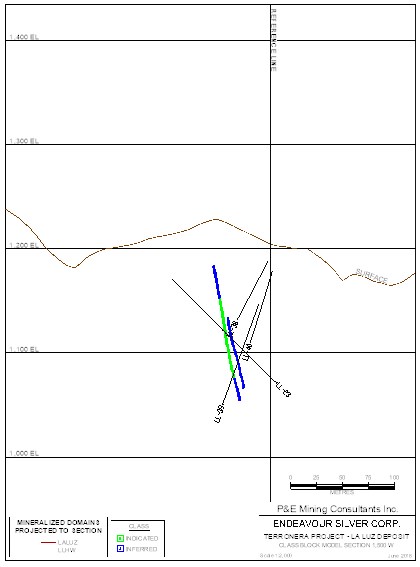

| Figure 14-60 | Classification Block Model Vertical Cross Section 1,150 W, La Luz Deposit | 14-55 |

| Figure 14-61 | Classification Block Model Vertical Cross Section 1,400 W, La Luz Deposit | 14-55 |

| Figure 14-62 | Classification Block Model Vertical Cross Section 1,500 W, La Luz Deposit | 14-56 |

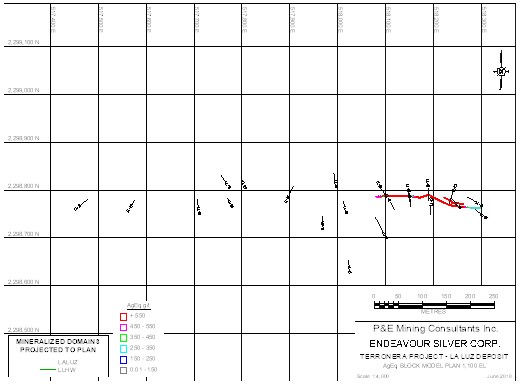

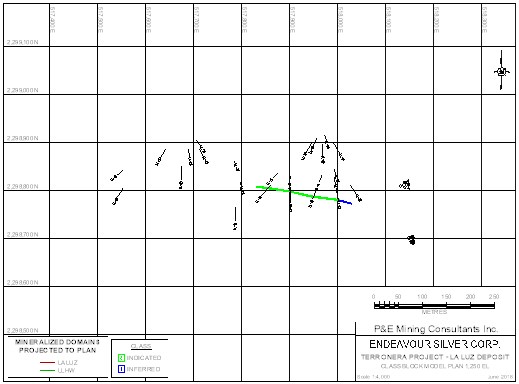

| Figure 14-63 | Classification Block Model Plan 1,250 m Elevation, La Luz Deposit | 14-57 |

| Figure 14-64 | Classification Block Model Plan 1,150 m Elevation, La Luz Deposit | 14-57 |

| Figure 14-65 | Classification Block Model Plan 1,050 m Elevation, La Luz Deposit | 14-58 |

| Figure 16-1 | Terronera Deposit Longitudinal Projection | 16-2 |

| Figure 16-2 | La Luz Deposit Longitudinal Projection | 16-3 |

| Figure 16-3 | Terronera and La Luz Plan View | 16-5 |

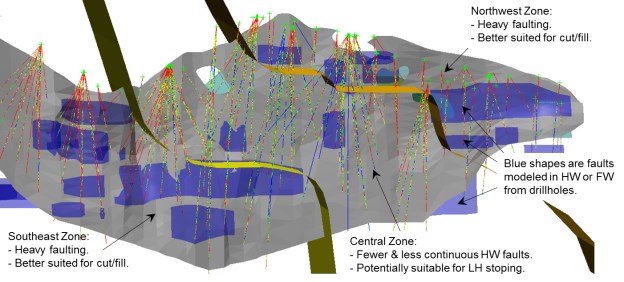

| Figure 16-4 | Schematic Section Showing Terronera Geotechnical Domains (Oblique View Looking Southwest) | 16-7 |

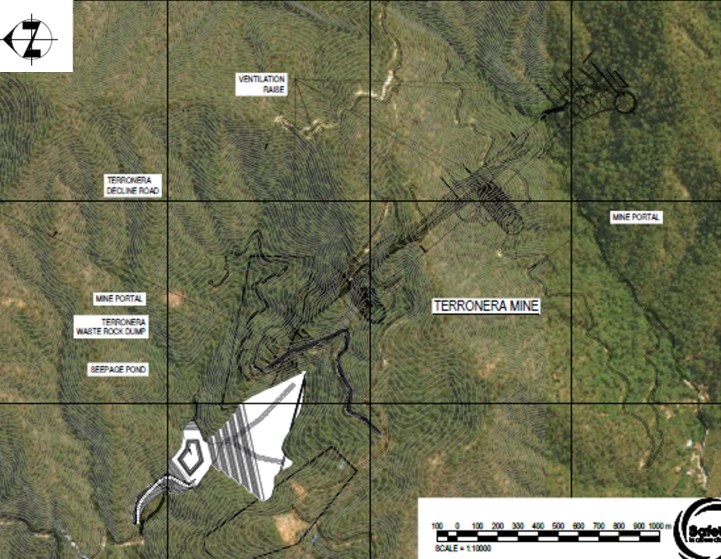

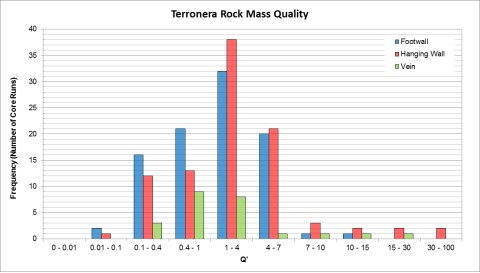

| Figure 16-5 | Distribution of Terronera Rock Mass Quality Parameter Q’ | 16-8 |

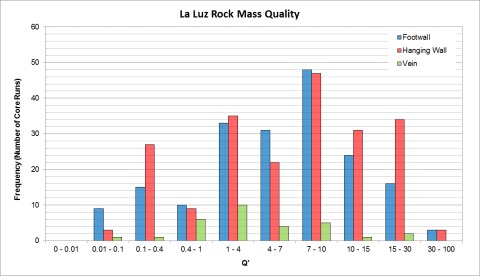

| Figure 16-6 | Distribution of La Luz Rock Mass Quality Parameter Q’ | 16-8 |

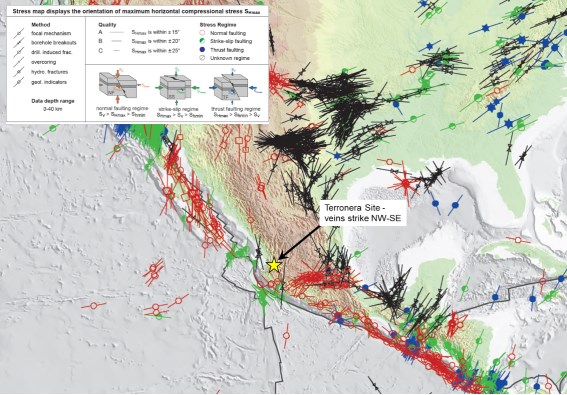

| Figure 16-7 | Estimated Stress Orientation | 16-9 |

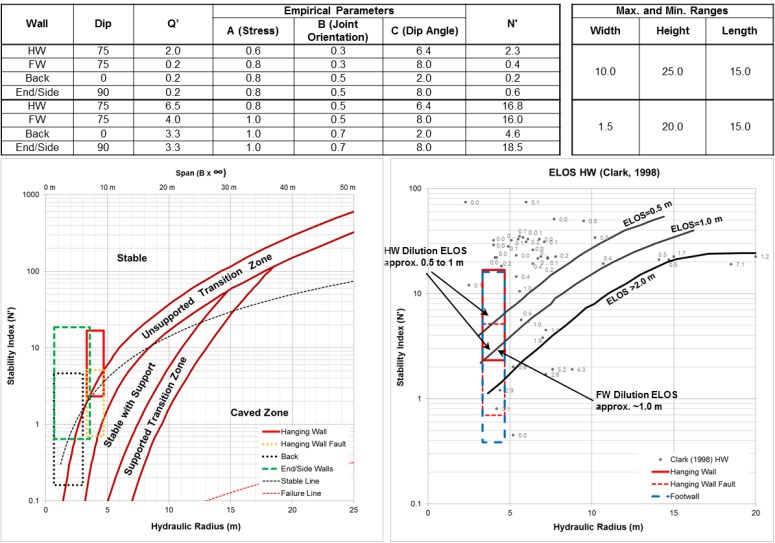

| Figure 16-8 | Empirical Stope Stability and Dilution Charts for Terronera Longitudinal LH Stopes | 16-11 |

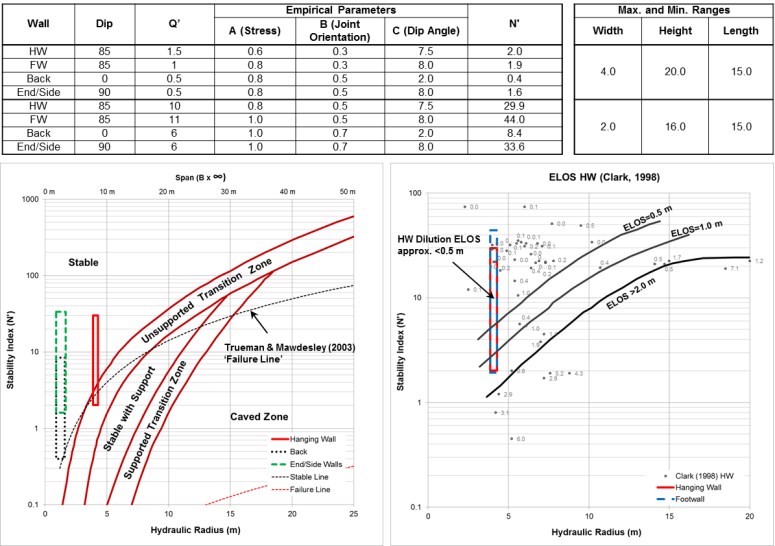

| Figure 16-9 | Empirical Stope Stability and Dilution Charts for La Luz Longitudinal LH Stopes | 16-12 |

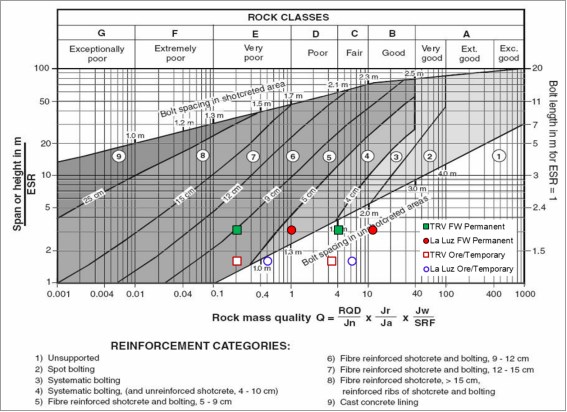

| Figure 16-10 | Barton’s Q Ground Support Chart | 16-14 |

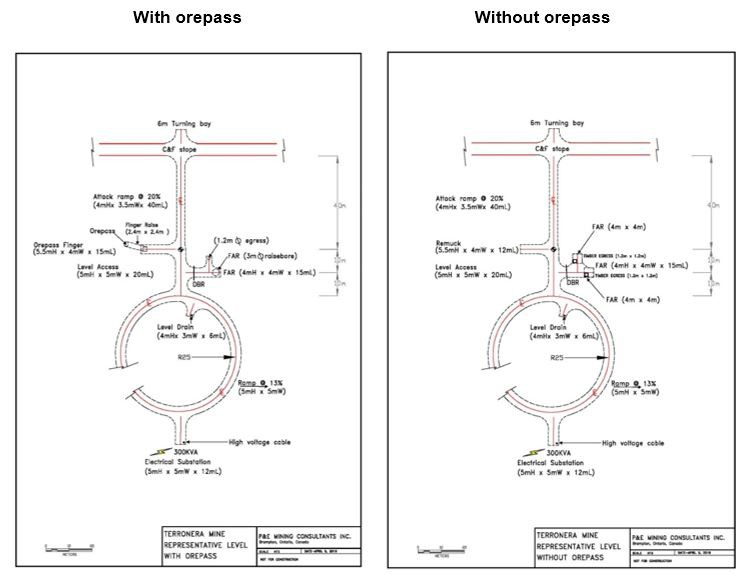

| Figure 16-11 | Representative Level Drawings | 16-20 |

| Figure 17-1 | Overall Process Flow Sheet | 17-2 |

| Figure 17-2 | Overall Process Flow Sheet | 17-4 |

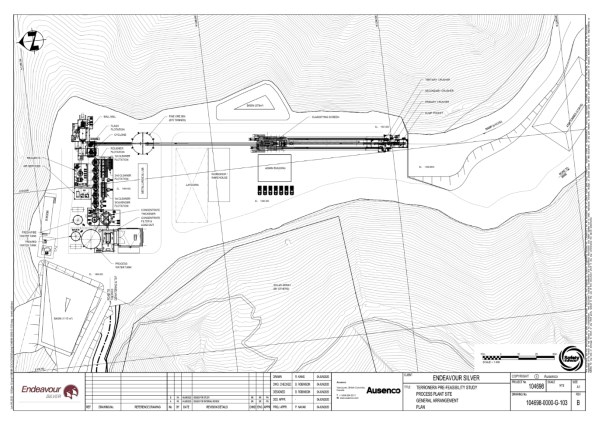

| Figure 18-1 | Map of Proposed Major Project Infrastructure | 18-2 |

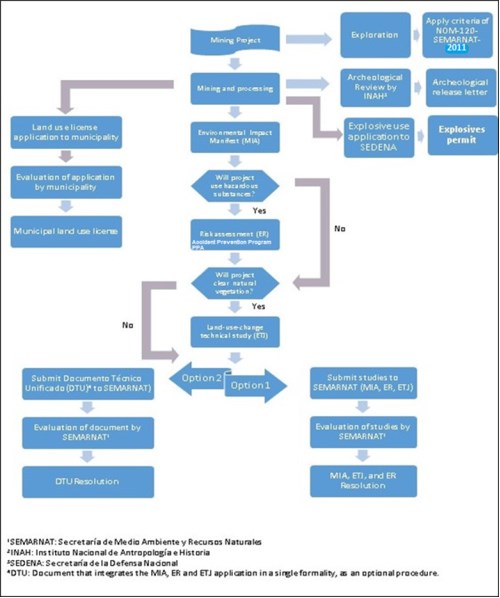

| Figure 20-1 | Environmental Permitting Steps for Mining Projects in Mexico | 20-2 |

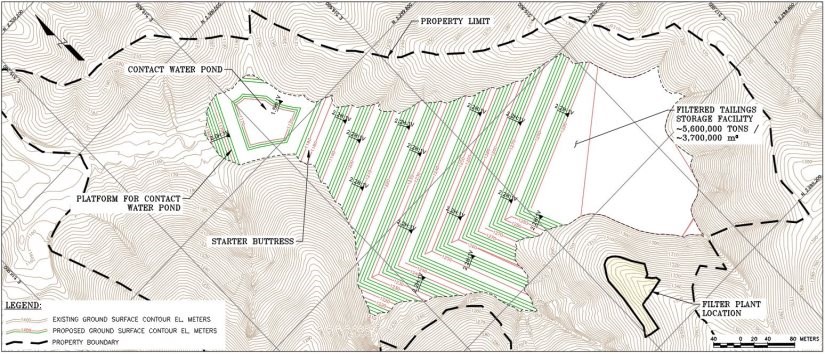

| Figure 20-2 | Map of the TSF Layout | 20-11 |

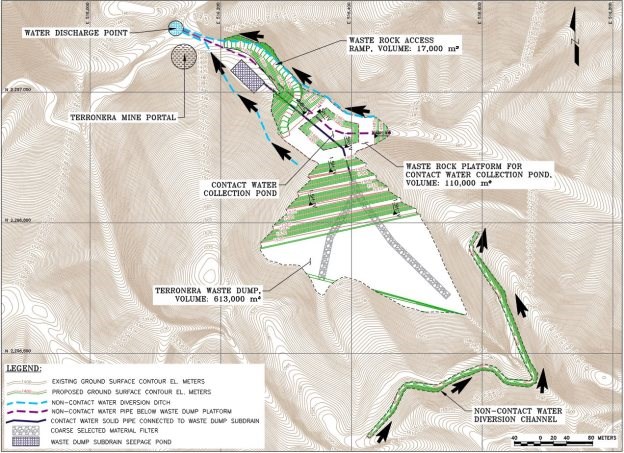

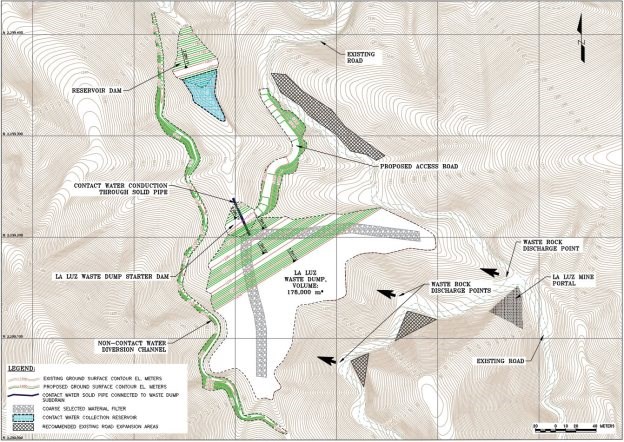

| Figure 20-3 | Proposed Layout of the La Luz Temporary Waste Dump | 20-14 |

104698-02-RX-RPT-001

Rev: A

Date: July 31, 2020

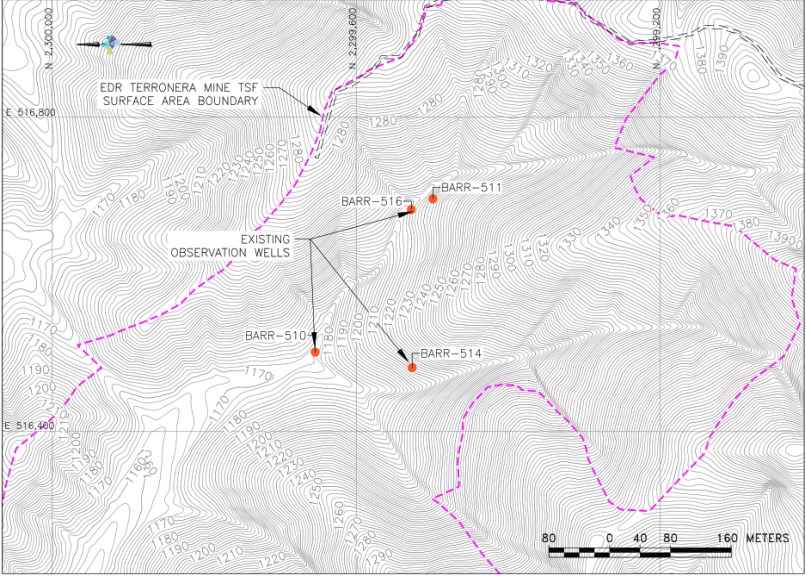

| Figure 20-4 | Map of the Mondeño Tailings Storage Area Monitoring Well Locations | 20-16 |

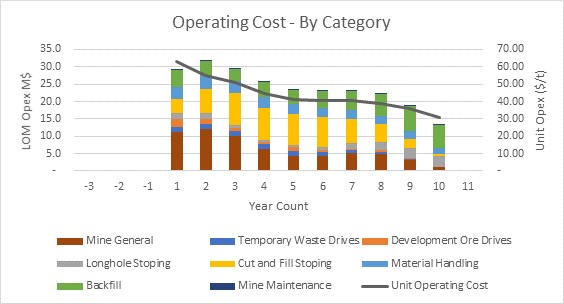

| Figure 21-1 | Total Mine Operating Cost | 21-15 |

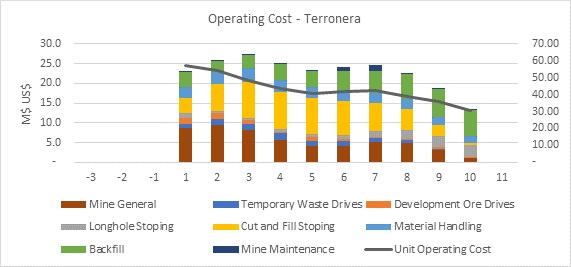

| Figure 21-2 | Operating Cost for Terronera Deposit | 21-15 |

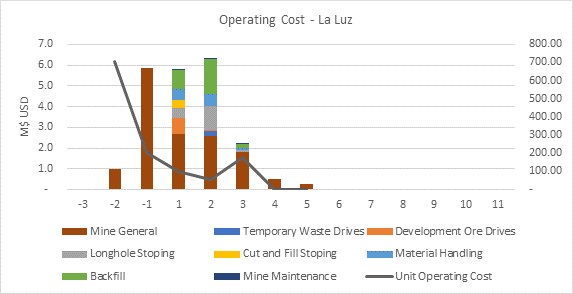

| Figure 21-3 | Operating Cost for La Luz Deposit | 21-16 |

| Figure 22-1 | Project Economics Graph | 22-4 |

104698-02-RX-RPT-001

Rev: A

Date: July 31, 2020

Certificates

Robin Kalanchey, P.Eng.

l, Robin Kalanchey, P.Eng. am employed as the Director, Minerals and Metals – Western Canada with Ausenco Engineering Canada Inc. (Canada), with an office at 855 Homer Street, Vancouver, BC V6B 2W2.

This certificate applies to the technical report entitled « Endeavour Silver Corp Terronera Project NI 43-101 Technical Report » prepared for Endeavour Silver Corp. (the « Issuer ») that has an effective date of July 14, 2020 (the « Technical Report »).

1. I graduated from the University of British Columbia in 1996 with a Bachelor of Applied Science degree in metals and materials engineering.

2. I am a Professional Engineer registered with the Association of Professional Engineers and Geoscientists of Alberta, member number 61986.

3. I have practiced my profession continuously since 1996 and have been involved in: mineral processing and metallurgical testing, metallurgical process plant design and engineering, and metallurgical project evaluations for gold, nickel, cobalt, copper, zinc and molybdenum projects in numerous countries.

4. I have not visited the Terronera Project.

5. As a result of my experience and qualifications, I am a Qualified Person as defined in National Instrument 43-101 Standards of Disclosure for Mineral Projects (« NI 43-101 ») for those sections of the technical report that I am responsible for preparing.

6. I am independent of the Issuer as defined in Section 1.5 of NI 43-101.

7. I am responsible for sections 1.1, 1.11, 1.15, the introductory paragraph including Figure 1.6 of 1.16, 1.16.1, 1.16.2, 1.16.4, 1.16.5, 1.17 1.19, 1.20, 1.21.1, 1.21.5-1.21.7, 2, 3.1, 13, 17, 18.1-18.4, 18.6-18.10, 18.13, 19, 21.1, 21.2, 21.4, 22, 23, 24, 25.6, 25.7, 25.9-25.12, 26.4-26.6, 26.10 and 27 of the Technical Report,.

8. I have no previous involvement with the Terronera Project.

9. I have read NI 43-101 and the sections of the Technical Report for which I am responsible have been prepared in compliance with that Instrument.

10. As of the effective date of the Technical Report, to the best of my knowledge, information and belief, the sections of the Technical Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make the Technical Report not misleading.

Dated: July 31, 2020

Signature: [SIGNED AND SEALED]

Name: Robin Kalanchey, P.Eng.

Michael Petrina, P. Eng., British Columbia (Mining)

Moose Mountain Technical Services

P.O. Box 820, 135 Devonshire Avenue

Iroquois Falls, ON

Canada

P0K 1E0

Telephone: 705-465-4555

Email: mikep@moosemmc.com

I Michael Petrina, P. Eng., British Columbia (Mining) certify that

I am Principal Mining Engineer (Underground) at Moose Mountain Technical Services P.O. Box 820, 135 Devonshire Avenue, Iroquois Falls, ON, Canada, P0K 1E0.

This certificate applies to the Technical Report titled Endeavour Silver Corp Terronera Project NI 43-101 Technical Report” prepared for Endeavour Silver Corp. (the « Issuer ») that has an effective date of July 14, 2020 (the « Technical Report »).

My qualifications and relevant experiences are that:

1. I graduated with a Bachelor of Science, Mining Engineering from Queen’s University in December 1983.

2. I am a member of the Professional Engineers of British Columbia.

3. I have worked as a in mining engineering for a total of 30 years.

4. I have read the definition of Qualified Person set out in Nation Instrument 43-101 (NI 43-101) and certify that by reason of my education, affiliation with a professional association and past relevant work experience, I fulfil the requirements to be a Qualified Person for the purposes of NI 43-101.

5. I have not visited the Property. I am responsible for the preparation of sections 1.13, 1.14, 1.21.4, 15, 16.1, 16.3-16.11, 25.5.2, 25.5.3, 26.3 and 27 of the Technical Report.

6. I am independent of the issuer per Section 1.5 or NI 43-101.

7. I have not had prior involvement with the property that is the subject of the Technical Report.

8. I have read National Instrument 43-101 and the Technical Report has been prepared in compliance with that Instrument.

9. As of the date of the certificate, to the best of my knowledge, information and belief, the Technical Report contains all material scientific and technical information that is required to be disclosed to make the Technical Report not misleading.

Dated: July 31, 2020

Signature: [SIGNED AND SEALED]

Name: Michael Petrina, P.Eng.

Humberto F. Preciado, P.E.

Wood Environment & Infrastructure Solutions, Inc.

2000 S Colorado Blvd

Suite 2-1000

Denver, CO 80222

USA

Telephone:303-630-0782

Facsimile:303-935-6505

Email: humberto.preciado@woodplc.com

I Humberto F. Preciado, P.E. certify that

I am a Senior Associate Geotechnical Engineer at Wood, 2000 S Colorado Blvd, Co 80222, USA

This certificate applies to the Technical Report titled Endeavour Silver Corp Terronera Project NI 43-101 Technical Report” prepared for Endeavour Silver Corp. (the « Issuer ») that has an effective date of July 14, 2020 (the « Technical Report »).

My qualifications and relevant experiences are that:

1. I graduated with a Doctorate in Civil Engineering from the University of British Columbia.

2. I am a member of the Society for Mining, Metallurgy & Exploration and the Canadian Dam Association. I am a registered Professional Engineer (Civil) in the States of Arizona, Colorado and Nevada.

3. I have worked as a Civil/Geotechnical Engineer for a total of 23 years. During this time I have conducted and reviewed multiple environmental studies, statements, as well as civil and geoenvironmental design of waste storage facilities for infrastructure and mining projects/operations

4. I have read the definition of Qualified Person set out in Nation Instrument 43-101 (NI 43-101) and certify that by reason of my education, affiliation with a professional association and past relevant work experience, I fulfil the requirements to be a Qualified Person for the purposes of NI 43-101.

5. I have visited the Property for a total of 4 days in December 11-14, 2015.