- Nettoyeur haute pression thermique AgriEuro Top-Line EWD-K 15/310- Moteur Honda GX 390Pays de fabrication Italie, Typologie À chariot, Activation moteur thermique, Sur roues, modèle de moteur GX390, Type de moteur 4 temps, Cylindrée 389cm³, Puissance nominale 13HP, Système de décompression automatique, Marque du moteur Honda , Matériau culasse Laiton, Type pompe à 3 pistons en ligne, Variateur de pression, Débit horaire max 900L/h, Pression max 310bars, Pompe linéaire Pro, Chariot (roues et poignées) , Poids 50Kg

- Nettoyeur haute pression thermique AgriEuro Top-Line EWD-K 15/310 - Moteur Loncin G390FPays de fabrication Italie, Typologie À chariot, Activation moteur thermique, Sur roues, modèle de moteur G390F, Type de moteur 4 temps, Cylindrée 389cm³, Puissance nominale 13HP, Système de décompression automatique, Marque du moteur Loncin, Matériau culasse Laiton, Type pompe à 3 pistons en ligne, Variateur de pression, Débit horaire max 900L/h, Pression max 310bars, Pompe linéaire Pro, Poids 50Kg

- VALEO Kit d'embrayage + Volant moteur pour VOLKSWAGEN: Golf, Touran, Transporter, Passat, Caddy, Jetta & AUDI: A3 & SEAT: Leon, Altea (Ref: 835035)VALEO Kit d'embrayage + Volant moteur pour VOLKSWAGEN: Golf (V,V Plus,VI Plus,V SW,V SW 4-Motion), Touran (I,I Phase 2), Transporter (T5 7H,T5 7J), Passat (B6 Berline,B6 SW), Caddy (III,III Maxi), Jetta (III 1K2,III Phase 2 1K2) & AUDI: A3 (Série 2 8P1,Série 2 Sportback,Série 2 Phase 2 Sportback,Série 2 Phase 2,Série 2 Cabriolet 8P) & SEAT: Leon (II 1P1,II 1P1 Phase 2), Altea ( XL, XL Phase 2,Phase 2,Phase 3), Toledo (série 3) & SKODA: Octavia (1Z3 Berline,1Z3 Berline Phase 2,1Z5 Combi Phase 2,1Z5 Combi), Superb (II,II Combi) (Ref : 835035) équivalente à AUDI: 03G105264C, 03G105264D, 03G105264G, 03G105266AC, 03G105266BA, 03G105266BM, 03L105266BS, 03L105266E, 3G105264C, 3G105264D, 3G105264G, 3G105266AC, 3G105266BA, 3G105266BM, 3L105266BS, 3L105266E & SEAT: 03G105264G, 03G105266AC, 03G105266BA, 03G105266BM, 03L105266BS, 03L105266E, 3G105264G, 3G105266AC, 3G105266BA, 3G105266BM, 3L105266BS, 3L105266E & SKODA: 03G105264G, 03G105266AC, 03G105266BA, 03G105266BM, 03L105266BS, 03L105266E, 3G105264G, 3G105266AC, 3G105266BA, 3G105266BM, 3L105266BS, 3L105266E & VW: 03G105264G, 03G105266AC, 03G105266AL, 03G105266BA, 03G105266BM, 03G105266E, 03L105266BS, 03L105266E, 3G105264G, 3G105266AC, 3G105266AL, 3G105266BA, 3G105266BM, 3G105266E, 3L105266BS, 3L105266E Avec butée d'embrayage : Oui, Type de volant moteur : Volant moteur rigide, gamme équipementier : KIT4P - CONVERSION KIT, Composition : Volant moteur, disque, mécanisme et butée mécanique, fonctionnement du volant moteur : Conversion, type de fonctionnement : poussé, Poids : 15.6 kg, Angle de serrage [degré] : 90.0 °, Couple de serrage : 60.0 Nm, marque : VALEO, avec consigne : non, disque d'embrayage : oui, mécanisme d'embrayage : oui, but du produit : Le volant moteur à deux masses, dit bi-masse et l'embrayage transmettent la force de rotation du vilebrequin du moteur à l'arbre primaire de la boîte de vitesse, avec mécanisme de désaccouplement et réaccouplement progressif qui permet le passage des vitesses. Une partie du volant moteur est boulonné au vilebrequin qui l'entraine, la seconde partie qui supporte le kit d'embrayage, permet d'amortir les chocs, changement de régime et acyclismes du régime moteur transmis à la boite de vitesses par un système à ressort sophistiqué. Pour une protection de la mécanique mais aussi pour un confort de conduite, le kit d'embrayage constitué d'un disque, un mécanisme et d'une butée permet d'entrainer la boîte par l'arbre primaire relier au disque, la butée qui actionne le mécanisme libère le disque de l'entrainement du moteur à chaque appuis sur la pédale d'embrayage pour un changement de rapport. Un kit d'embrayage + volant moteur vous permet de refaire entièrement l'embrayage de votre voiture. Il est généralement livré avec un jeu de boulons et le lubrifiant nécessaire., quand changer : Selon les modèles, votre style de conduite et la nature de vos parcours habituels, un embrayage dure aux alentours de 150000 km. Le symptôme classique d'usure est la...

- Pompe Piscine Max Flo Hayward - 1.5cv 15m³/h TriLa pompe Max Flo d'Hayward est performante, silencieuse et peu gourmande en énergie. Elle s'adapte aux piscines de petites et moyenne tailles. Plébiscitée par un grand nombre d'utilisateurs, elle est une référence dans sa catégorie. La Max Flo est une pompe hayward auto amorçante et s'adapte à l'eau salée pour une compatibilité avec les électrolyseurs.

- Pompe piscine STA RITE PENTAIR de 16 m3/h (1CV ) - TriphaséPompe piscine STA - RITE modèle P-STR La pompe piscine STA - RITE est la pompe la plus haut de gamme, résistante à toutes épreuves, des rendement surpuissant, un moteur ultra silencieux. Le moteur bénéfice de la technologie PENTAIR éprouvé et efficace renforcé en fibre de verre, une turbine haute pression pour un débit maximale COMPATIBLE ELECTROLYSEUR - Pompe STA RITE 5P2R de 3/4 à 1.5 CV en mono La pompe STA - RITE de la série 5P2R est en matériau de synthèse renforcé à la fibre de verre et obtenue par moulage de haute précision. Moteur Moteur européen conforme aux normes “CE” et muni d’une protection IP 55. La conception spéciale du diffuseur assure un auto-amorçage très efficace. Embase La pompe STA RITE 5P2R est montée sur une embase surélevée, stable, rigide et antivibrations. La hauteur de l’embase préserve le moteur de l’humidité et des souillures. Collier d’assemblage Le collier d’assemblage, en acier inoxydable, permet un démontage rapide de l’ensemble et un accès aisé aux pièces mobiles. Obtenue par le moulage sous pression, la turbine est conçue pour délivrer une hauteur manométrique élevée. Sa finition et son équilibrage dynamique lui assurent un fonctionnement silencieux et un excellent rendement. Le couvercle transparent du préfiltre permet facilement de vérifier l’état de colmatage du panier. Le couvercle a un ø de 127 mm et résiste à une pression de 4 bar. le panier du préfiltre est verrouillable et protège la turbine des impuretés. Construction Le matériau utilisé pour la fabrication de la pompe sta rite et du préfiltre autorise une pression de service élevée. Testé pendant plusieurs années ce matériau a des caractéristiques incomparables et résiste même à des variations de températures importantes. Presse-étoupe Comme sur des millions de pompes STA-RITE une étanchéité parfaite est obtenue par le presse-étoupe en céramique de carbone finement polie et surfacée. Données Techniques La pompes de la série 5P2R est une pompe centrifuge qui est principalement conçue pour l’application dans la piscine, en combinaison avec un filtre de piscine.

- Pompe piscine STA RITE PENTAIR de 16 m3/h (1CV ) - TriphaséPompe piscine STA - RITE modèle P-STR La pompe piscine STA - RITE est la pompe la plus haut de gamme, résistante à toutes épreuves, des rendement surpuissant, un moteur ultra silencieux. Le moteur bénéfice de la technologie PENTAIR éprouvé et efficace renforcé en fibre de verre, une turbine haute p

- Pompe vide piscine - IntexLa pompe vide piscine Intex est le produit idéal pour vider votre piscine en toute simplicité. Facile à utiliser, il suffit de brancher l'appareil sur le secteur et de le positionner au fond de votre bassin. La pompe se chargera de vider l'eau restante en un temps record (pompe jusqu'à 3595 litres d'eau/heure) là où vous le souhaitez. La pompe dispose d'une protection IPX8, ce boitier étanche et compact peut se connecter à un tuyau de 5 mètres ou à un tuyau d'arrosage à l'aide d'un adaptateur compris dans le kit. La pompe vide piscine Intex fonctionne avec une hauteur d'eau de 1m22 maximum. Au-delà de cette limite, l'appareil se mettra en sécurité.

- Gré Pompe piscine Gre Premium Modèle - 1,00 CV - 12 m3/hPompe de filtration Gre Premium Pompe auto-amorçante avec préfiltre pour piscine La pompe piscine Premium Gre est l’élément le plus déterminant pour la qualité d’eau de votre piscine. Chargée d’acheminer l’eau depuis la buse d’aspiration/skimmer puis au travers du filtre et enfin jusqu’à la buse de refoulement de votre piscine. Avec une puissance d’aspiration constante, la pompe auto-amorçante Premium se destine aux piscines aux piscines hors-sol ainsi qu’aux piscines enterrées ayant un diamètre de tuyau de 38 ou 50mm. Avec son panier préfiltre intégré, cette pompe de piscine va capture les plus gros débris afin qu’ils n’endommagent pas l’hélice ou le moteur et n’encrassent pas prématurément votre filtre à sable. Facile d’ accès par le dessus de la pompe, vous pourrez contrôler son encrassement d’un simple coup d’oeil car il est protégé par un couvercle transparent. Aussi, vous verrez immédiatement quand il est nécessaire de le vider. Caractéristiques détaillées Modèle Gre Premium PP102 Gre Premium PP152 Gre Premium PP202 Puissance 1,00 CV / 900 W 1,50 CV / 1100 W 2,00 CV / 1600 W Débit min 12 m³/h 17 m³/h 21 m3/h Débit max 20 m3/h 22 m3/h 27 m3/h Volume de piscine maximal recommandé 100 m³ 135 m³ 170 m³ Raccordement hydraulique tuyaux de 38 ou 50 mm Diamètre de filtre à sable recommandé 600 mm 700 mm 800 mm Poids 6,00 kg 7,50 kg 10,70 kg Dimensions pompe 55,3 x 22 x 27,8 cm Garantie légale de conformité et des vices cachés : 2 ans

- Gré Pompe piscine Gre vitesse variable VSG75Pompe piscine Gre VSG 75 à vitesse variable 0,75CV monophasée Économique, silencieuse et performante. La pompe à vitesse variable est l’avenir de la filtration car elle répond à la fois aux exigences de performances et d’économies d’énergie. Avec le modèle VSG75, Gre met propose une pompe idéale pour tout type de piscine jusqu’à 65m³ qui permettra de garder une eau claire tout en maximisant les économies réalisées. Une circulation lente de l’eau améliore la qualité de la filtration. La pompe à vitesse variable assure une filtration constante à faible vitesse mais permet aussi un excellent nettoyage de votre filtre à sable lorsqu’elle est paramétrée en vitesse maximale. Avec ses quatre réglages de vitesse, la pompe VSG75 mono Gre permet un mélange plus homogène des produits dans votre piscine. En mode automatique, cette pompe de filtration vous permet de paramétrer différentes vitesses de fonctionnement en fonction de plages horaires pour que la pompe s’adapte réellement à vos besoins et selon vos habitudes de baignade. Le paramétrage est simplifié par une interface à 4 boutons intuitifs ainsi qu’une notice détaillée qui accompagnera le matériel. Caractéristiques techniques Moteur Vitesse variable Volume de piscine toute piscine jusqu’à 65 m³ Alimentation Monophasée 220-240 V, branchement sur prise secteur Débit maximal 19.54 m3/h Puissance d’entrée 750 W Vitesses de fonctionnement LOW : 1150 rpm MEDI : 1700 rpm HIGH : 2100 rpm FULL : 2850 rpm Diamètre du raccordement hydraulique propre 50 mm Température maximum en °C 35 Kit raccord union O/N Fourni, à coller pivotant Émissions sonores 53 à 59 dB Dimensions 55,3 x 22 x h.27,8cm Poids 9 kg Garantie légale de conformité et des vices cachés : 2 ans

- JetlineSelection FI 21kw 110m3 pompe à chaleur piscine PoolexJetlineSelection FI 21kw 110m3 pompe à chaleur piscine Poolex

- Bestway Pompe à chaleur HS35 pour piscine hors-sol<!-- <p class=indisponible><span class=message-indispo>Cet article est obsolète.</span><br /> > Consulter le rayon <a href=https://www.mypiscine.com/669-pompe-a-chaleur-piscine-hors-sol title=PAC piscine hors sol>Pompe à chaleur pour piscine hors-sol</a></p> --> <p>Pompe à chaleur Bestway HS35 pour piscine hors sol - 20m3/h</p> <ul> <li>A brancher sur une prise Plug & Play directement sur le secteur</li> <li>Pour piscine hors-sol jusqu'à 20m3</li> <li>Puissance : 3,5 KW</li> <li>Fonctionne dès 10°C</li> <li>Longueur tuyaux : 2 m</li> <li>Connexion : Ø 32 mm</li> <li>Débit pompe : 2 m3/h</li> <li>Dimensions : 37 x 29 x H 31 cm</li> <li>Panneau de contrôle intuitif avec 3 boutons</li> </ul>

- EXIT TOYS EXIT Piscine tubulaire Stone pompe filtre à sable 5,4x2,5x1,22 m, grisLa piscine Stone d'EXIT aux dimensions 540 x 250 x 122 cm est de forme rectangulaire grise. La grande piscine est fournie en série avec une pompe à filtre à sable et une échelle pour monter et sortir du bassin en sécurité. Le diamètre large de la piscine offre suffisamment d'espace pour se...

- Piscine tubulaire amovible Bestway Power Steel avec pompe à filtre 488x244x122 cmPiscine portable : Entièrement renforcée, elle possède une structure de tubes en aluminium galvanisé. Montage facile, avec un temps estimé à 60 minutes (voir vidéo), et démontage simple. Échelle de 122 cm, avec plateforme pour une plus grande stabilité. Couverture superficielle. Tapisserie de sol. Robinet de vidange avec raccord de tuyau. DVD d'exploitation et d'entretien. Cette piscine hors sol amovible se démarque par sa simplicité de montage et de démontage et son entretien facile. De forme rectangulaire et de couleur gris clair, cette piscine hors sol renforcée est très résistante à une éventuelle corrosion grâce à sa structure tubulaire en aluminium galvanisé et ses parois latérales renforcées de PVC haute densité. La doublure est composée de trois couches, dont deux en PVC haute densité et une couche centrale en polyester. Fabriqué par soudure haute fréquence, le liner reçoit également un traitement ultraviolet pour protéger sa couleur. Pour faciliter le drainage et la vidange, la piscine est équipée d'un robinet de vidange et d'un adaptateur de tuyau d'arrosage standard. Il comprend également une échelle d'accès à la piscine de 122 cm avec une plateforme intégrée pour une plus grande stabilité. Ce modèle de piscine comprend également une couverture de surface, un tapis de sol et un DVD expliquant le fonctionnement et l'entretien. Le temps estimé pour le montage de chaque piscine est une évaluation faite dans des conditions normales, une fois la dalle préparée pour commencer l'installation.

- BESTWAY Fast Set Piscine hors sol motif rotin gris, 396 x 84 cm, avec pompe 57376Facile et rapide a monter, le kit piscine Fast Set™ de Bestway® vous permettra de vous prélasser au bord de votre nouvelle piscine en un rien de temps. Cette piscine est idéale pour amuser vos enfants et leur faire découvrir le plaisir d’une baignade et les joies de la piscine en toute sécurité. Les enfants vont adorer passer leurs journées d’été a s’éclabousser et a jouer dans l’eau, et les parents pourront également profiter d’une baignade agréable et relaxante. La pompe de filtration inclue avec la piscine vous aidera a garder une eau propre. Avec son liner effet rotin, elle apportera une petite touche de décoration a votre jardin. L’été n’est pas vraiment l’été sans la piscine Fast Set™ de Bestway® ! Caractéristiques: Dimensions: 396 x 84 cm Volume d'eau a 80%: 7 340 L Débit de la pompe: 2 006 L Compatibilité des cartouches: Cartouche 58094 (II) Matériau: Duraplus™ Temps de montage: 10 minutes Contenu: 1 piscine 1 pompe de filtration 1 cartouche de filtration Technologies: Avec son procédé d’installation ultrasimple Fill & Rise™, pas de prise de tete ! Il vous suffit de choisir une surface plane, de gonfler l’anneau supérieur et la piscine se levera au fur et a mesure qu’elle se remplira d'eau. Le liner est fabriqué en DuraPlus™, un matériau extremement résistant fait de 3 épaisseurs renforcées, 85 % plus résistant a la perforation que le PVC. Il est réputé pour sa résistance a la perforation, sa durabilité et sa longévité. Photo d'illustration>

- Pompe à chaleur Poolex Nano Action-3 kW / 10 à 21m3POOLEX NANO ACTION LA PAC POUR LES PETITS BASSINS Nous vous recommandons cette pompe à chaleur Poolex Nano Action ; en effet cette PAC pour petits bassins à tout d'une grande ! Elle est, en outre, compatible avec les piscines hors sol. DESCRIPTION DE LA PAC NANO POOLEX ACTION La PAC fabriquée spécialement pour les petits bassins. Elle convient pour différents types de bassins : les piscines avec structure tubulaire, les piscines hors sols ou encore les piscines enterrées. Bien qu'elle soit plus petit, elle dispose d' un COP similaire aux pompes à chaleur haut de gamme, la NANO arrive à talonner ses grands frères Jetline et Silverline. Dotée d'une prise électrique classique, chauffez votre piscine en quelques heures et sans effort ! Son design unique et très compact fait l'une des meilleures mini PAC du marché . Offrez-vous la performance d'une Poolex au meilleur prix. AVANTAGES POOLEX NANO ACTION R32 : Dimensions compactes Raccords sur filtration standard Transportable (15kg) Economique et silencieuse (moins de 33dB à 10 mètres) Système électrique sécurisé Système Plug & Play Fonctionne à partir de 8°C 100% sécurisée Pompe à chaleur garantie 2 ans Pourquoi choisir NANO ACTION ? Plug & play Fonctionne à partir de 8°C Compatible toutes piscines hors sol Légère et compacte Ultra silencieuse Économique Accessoires inclus avec la Poolex Nano Action Votre pompe à chaleur POOLEX NANO ACTION, vous est livrée : dans un emballage à structure renforcée avec un manuel d'installation et d'utilisation multi-langues avec une prise électrique d'une longueur de 5 mètres avec protection différentielle de 10mA avec des connecteurs PVC de diamètre 32-38mm Principes et avantages de la pompe à chaleur piscine Bien que son acquisition s'avère relativement onéreuse, la pompe à chaleur POOLEX NANO ACTION consomme très peu d'énergie lorsqu'elle fonctionne. En effet, elle restitue jusqu'à cinq fois plus d'énergie qu'elle n'en consomme puisque l'énergie principalement utilisée pour générer de la chaleur est issue de l'air extérieur, une source d'énergie renouvelable. Le coût initial de la pompe à chaleur est donc rapidement amorti grâce aux économies énergétiques qu'elle permet . À titre d'exemple, pour 600W d'énergie consommée, elle restitue 3000W de chauffage. Caractéristiques de la pompe à chaleur Poolex NANO Action POINT FORT : Avec un prix imbattable et une performance inégalée pour ce petit gabarit, la POOLEX NANO est la PAC que tout le monde peut acquérir et installer très facilement ! Lancez vous sans hésiter ! Découvrez également la POOLEX NANO ACTION RÉVERSIBLE Pompe à chaleur POOLEX NANO Action Réversible R32 - Pour petit bassin jusqu'à 35m3 - COP de 5,3 - S'installe facilement - Meilleur rapport Qualité/Prix - Ultra légère : 15Kg - Economique et ultra Silencieuse - Nouveau fluide réfrigérant écologique R32 POOLEX NANO ACTION RÉVERSIBLE : LA PAC POUR LES PETITS BASSINS ET SPAS eROBOT-PISCINE.fr vous propose la pompe à chaleur de piscine Poolex NANO ACTION...

- Kit By Pass Deluxe pour pompe à chaleur - UbbinkPour installer votre pompe à chaleur pour la piscine, il est indispensable de créer un << by-pass >> sur votre installation. Il s'agit d'une dérivation sur votre canalisation de filtration. Le Kit By Pass est compatible avec tuyauterie diamètres 50 et 38 mm : 2 coudes 90° à coller, 2 té 90° à coller, 3 vannes, 2 raccords cannelés 50 x 38 à coller, 1 colle 125 ml, 1 décapant 500 ml.

- Piscine gonflable Intex Easy Set 28122NP + Pompe filtrePays de fabrication Chine, Forme Ronde, Hauteur piscine 76cm, Capacité piscine 3853L, Largeur piscine 305cm, Hauteur max de l'eau 53cm, N°de personnes Max 3-4, Débit horaire max 1250L/h, Filtre À cartouche

- Piscine Intex Rectangular Frame 28274NP + Pompe filtrePays de fabrication Chine, Forme Rectangulaire, Longueur piscine 450cm, Largeur piscine 220cm, Hauteur piscine 84cm, Hauteur max de l'eau 72cm, Capacité piscine 7127L, N°de personnes Max 5-6, Débit horaire max 2006L/h, Filtre À cartouche

- Pompe Piscine Max Flo Hayward - 1cv 13m³ TriLa pompe Max Flo d'Hayward est performante, silencieuse et peu gourmande en énergie. Elle s'adapte aux piscines de petites et moyenne tailles. Plébiscitée par un grand nombre d'utilisateurs, elle est une référence dans sa catégorie. La Max Flo est une pompe hayward auto amorçante et s'adapte à l'eau salée pour une compatibilité avec les électrolyseurs.

- Pompe Piscine Max Flo Hayward - 1.5cv 15m³/h MonoLa pompe Max Flo d'Hayward est performante, silencieuse et peu gourmande en énergie. Elle s'adapte aux piscines de petites et moyenne tailles. Plébiscitée par un grand nombre d'utilisateurs, elle est une référence dans sa catégorie. La Max Flo est une pompe hayward auto amorçante et s'adapte à l'eau salée pour une compatibilité avec les électrolyseurs.

- Pompe Piscine Max Flo Hayward - 0.75cv 11m³/h TriLa pompe Max Flo d'Hayward est performante, silencieuse et peu gourmande en énergie. Elle s'adapte aux piscines de petites et moyenne tailles. Plébiscitée par un grand nombre d'utilisateurs, elle est une référence dans sa catégorie. La Max Flo est une pompe hayward auto amorçante et s'adapte à l'eau salée pour une compatibilité avec les électrolyseurs.

- Pompe Piscine Max Flo Hayward - 1cv 13m³/h MonoLa pompe Max Flo d'Hayward est performante, silencieuse et peu gourmande en énergie. Elle s'adapte aux piscines de petites et moyenne tailles. Plébiscitée par un grand nombre d'utilisateurs, elle est une référence dans sa catégorie. La Max Flo est une pompe hayward auto amorçante et s'adapte à l'eau salée pour une compatibilité avec les électrolyseurs.

- Pompe Piscine Max Flo Hayward - 0.75cv 11m³/h MonoLa pompe Max Flo d'Hayward est performante, silencieuse et peu gourmande en énergie. Elle s'adapte aux piscines de petites et moyenne tailles. Plébiscitée par un grand nombre d'utilisateurs, elle est une référence dans sa catégorie. La Max Flo est une pompe hayward auto amorçante et s'adapte à l'eau salée pour une compatibilité avec les électrolyseurs.

- Pompe Piscine Max Flo Hayward - 0.5cv 8m³/h MonoLa pompe Max Flo d'Hayward est performante, silencieuse et peu gourmande en énergie. Elle s'adapte aux piscines de petites et moyenne tailles. Plébiscitée par un grand nombre d'utilisateurs, elle est une référence dans sa catégorie. La Max Flo est une pompe hayward auto amorçante et s'adapte à l'eau salée pour une compatibilité avec les électrolyseurs.

- Pompe Piscine Max Flo HaywardLa pompe Max Flo d'Hayward est performante, silencieuse et peu gourmande en énergie. Elle s'adapte aux piscines de petites et moyenne tailles. Plébiscitée par un grand nombre d'utilisateurs, elle est une référence dans sa catégorie. La Max Flo est une pompe hayward auto amorçante et s'adapte à l'eau salée pour une compatibilité avec les électrolyseurs.

- Pompe Piscine Swimmey (Nocchi) Pentair - 1cv 13m³/h Monophasée (SW19)La pompe Swimmey de Pentair est une pompe autoamorçante présentant un excellent rapport qualité prix. La pompe Swimmey est compatible avec le traitement au sel. Elle remplace l'ancien modèle NOCCHI et s'adapte en remplacement sans modification de plomberie.

- Pompe Piscine Swimmey (Nocchi) Pentair - 1.5cv 19m³/h Monophasée (SW28)La pompe Swimmey de Pentair est une pompe autoamorçante présentant un excellent rapport qualité prix. La pompe Swimmey est compatible avec le traitement au sel. Elle remplace l'ancien modèle NOCCHI et s'adapte en remplacement sans modification de plomberie.

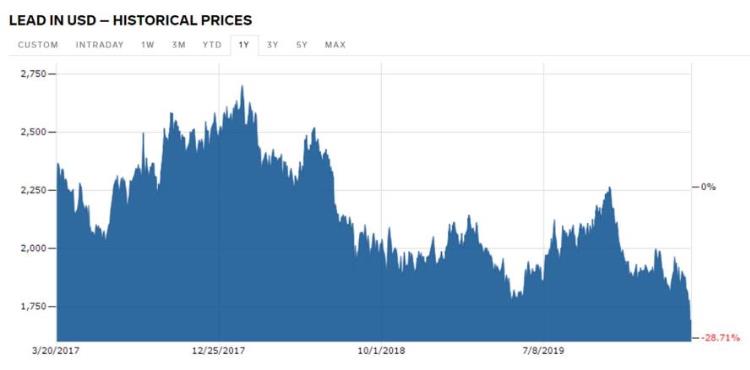

Get instant alerts when news breaks on your stocks. Claim your 1-week free trial to StreetInsider Premium here.

UNITED STATES

SECURITIES AND EXCHANGE

COMMISSION

Washington, D.C.

20549

FORM 6-K

REPORT OF FOREIGN PRIVATE ISSUER PURSUANT TO

RULE 13a-16 OR 15d-16 UNDER THE SECURITIES EXCHANGE ACT OF

1934

For the month of July 2020

Commission File No.

001-38145

Auryn Resources

Inc.

(Translation of registrant’s name into English)

Suite 600, 1199 West Hastings

Street

Vancouver, British Columbia, V6E 3T5

Canada

(Address of principal executive office)

Indicate by check mark

whether the registrant files or will file annual reports under

cover of Form 20-F or Form 40-F

Form

20-F [ ] Form

40-F [X]

Indicate by check mark

if the registrant is submitting the Form 6-K in paper as permitted

by Regulation S-T Rule 101(b)(1) [ ]

Indicate by check mark

if the registrant is submitting the Form 6-K in paper as permitted

by Regulation S-T Rule 101(b)(7) [ ]

SUBMITTED

HEREWITH

Exhibits

Technical Report,

Updated Mineral Resource Estimate and Preliminary Economic

Assessment on the Homestake Ridge Gold Project amended and

restated June 24, 2020

Consent of

Qualified Person – David Stone, P.Eng. amended and

restated June 24, 2020

Consent of

Qualified Person – Philip A Geusebroek, M.Sc., P.Geo

amended and

restated June 24, 2020

Consent of

Qualified Person – Paul Chamois, M.Sc.(A), P.Geo amended and

restated June 24, 2020

Consent of

Qualified Person – Mary Mioska, P.Eng. amended and

restated June 24, 2020

SIGNATURE

Pursuant to the

requirements of the Securities Exchange Act of 1934, the registrant

has duly caused this report to be signed on its behalf by the

undersigned, thereunto duly authorized.

| AURYN RESOURCES INC. |

| |

|

|

|

|

Date: July 21, | By: | /s/ Stacy |

|

|

| Stacy |

|

|

| Chief |

|

Technical

Report,

Updated

Mineral Resource Estimate and

Preliminary

Economic Assessment

on

the

HOMESTAKE

RIDGE GOLD PROJECT

SKEENA

MINING DIVISION

BRITISH

COLUMBIA

Latitude

55° 45′ 12.6″ N and Longitude 129° 34′ 39.8″

W

Qualified Persons:

Paul

Chamois, P.Geo.

Philip

Geusebroek, P.Geo.

Mary

Mioska, P.Eng.

David

M.R. Stone, P.Eng.

Prepared by:

MINEFILL

SERVICES, INC.

PO BOX

725

BOTHELL,

WASHINGTON

Effective Date: May 29, 2020

Amended and Restated: June 24, 2020

IMPORTANT NOTICE

This

report was prepared as a National Instrument 43-101 Technical

Report for the exclusive use of Auryn Resources Ltd.

(Auryn) by MineFill Services, Inc., (MineFill).

The quality of information, conclusions, and estimates contained

herein is consistent with industry standards based on i)

information available at the time of preparation, ii) data supplied

by outside sources, and iii) the assumptions, conditions, and

qualifications as set forth in this report. This report is intended

for use by Auryn subject to

the terms and conditions of its contract with MineFill. Except for

the purposes legislated under Canadian provincial and territorial

securities law, any other use of this report by any third party is

at that party’s sole risk.

Homestake

Ridge Project

NI43-101F1

Technical Report

Table of Contents

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

Effective Project |

|

Page i

Homestake

Ridge Project

NI43-101F1

Technical Report

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

Effective Project |

|

Page

ii

Homestake

Ridge Project

NI43-101F1

Technical Report

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

Effective Project |

|

Page

iii

Homestake

Ridge Project

NI43-101F1

Technical Report

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

Effective Project |

|

Page

iv

Homestake

Ridge Project

NI43-101F1

Technical Report

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

Effective Project |

|

Page v

Homestake

Ridge Project

NI43-101F1

Technical Report

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

Effective Project |

|

Page

vi

Homestake

Ridge Project

NI43-101F1

Technical Report

List of Tables

|

|

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

|

|

| |

|

|

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

Effective Project |

|

Page

vii

Homestake

Ridge Project

NI43-101F1

Technical Report

List of Figures

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

Effective Project |

|

Page

viii

Homestake

Ridge Project

NI43-101F1

Technical Report

1.

SUMMARY

1.1

Overview

The

subject of this document is the Homestake Ridge gold project

located in the so-called Golden Triangle of north-central British

Columbia. The Project is owned and operated by Auryn

Resources Inc. (the “Company” or “Auryn”)

of Vancouver, B.C. Auryn is listed on the Toronto stock

exchange and the New York Stock Exchange.

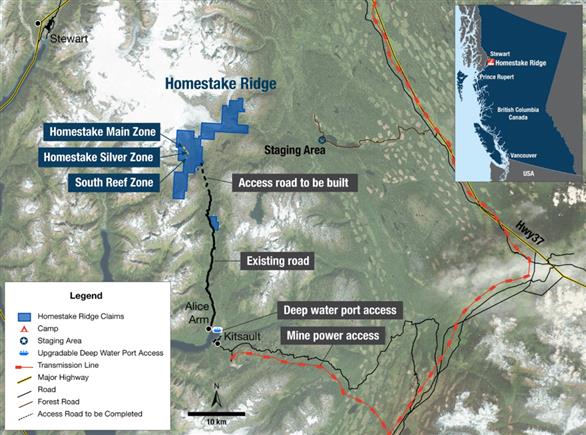

The

Homestake Ridge Project comprises 7,484.37 hectares (ha) of mineral

claims and crown grants and is located approximately 32 km

north-northwest of the tidewater communities of Alice Arm and

Kitsault, BC.

1.2

Geology

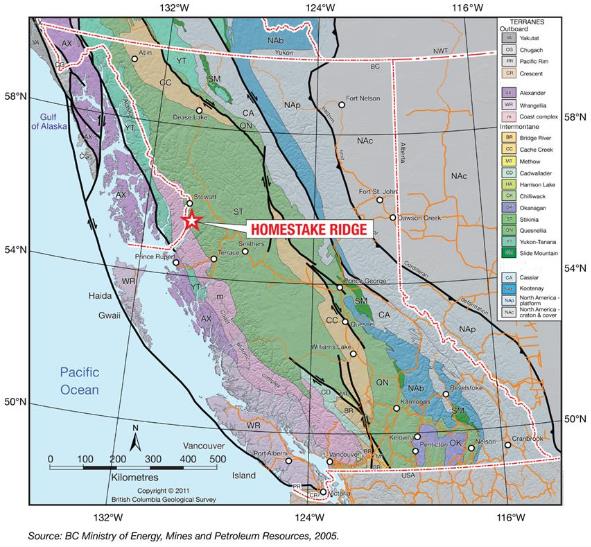

The

Project is located within the prolific Iskut-Stewart-Kitsault Belt

which hosts several precious and base metal mineral deposits.

Diverse mineralization styles include stratabound sulphide and

silica-rich zones, sulphide veins, and disseminated or stockwork

sulphides. Mineralization is related to Early Jurassic

feldspar-hornblende-phyric sub-volcanic intrusions and felsic

volcanism, which commonly occurs with zones of pyrite-sericite

alteration. Numerous genetic models can be proposed for the

area and local deposits present a broad range of

characteristics.

The

Project lies within the metallogenic region known as the Stewart

Complex. Described as the contact of the eastern Coast

Plutonic Complex with the west-central margin of the successor

Bowser Basin, the Stewart Complex ranges from Middle Triassic to

Quaternary in age and is comprised of sedimentary, volcanic, and

metamorphic rocks.

The

Project covers the transition between the sedimentary and volcanic

rocks of the Upper Triassic to Lower Jurassic Stuhini Group, a

complex sequence of Lower to Middle Jurassic sedimentary, volcanic,

and intrusive rocks of the Hazelton Group and sedimentary rocks of

the Upper to Middle Jurassic Bowser Lake Group.

In the

northern portion of the Project, at the headwaters of Homestake

Creek, rhyolitic volcanic rocks occur at the base of the Salmon

River sediments.

The

eastern portion of the Project is dominated by the Middle to Upper

Jurassic Bowser Basin Group which conformably overlies the thin

bedded graphitic argillites of the Salmon River

formation.

Effective Project |

|

Page

1-1

Homestake

Ridge Project

NI43-101F1

Technical Report

Structure

on the Project largely reflects northeast-southwest compression

that has continued from the Jurassic to present day. Recent

drilling and mapping suggest that the local stratigraphy has

undergone several deformation events including uplift and local

extension of the Stuhini and lower Hazelton stratigraphy.

Large northeast trending ankerite bearing faults have been mapped

and related to Tertiary east-west extension.

1.3

Mineralization

The

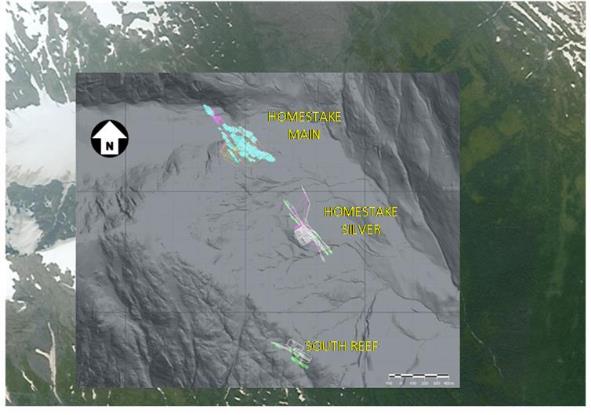

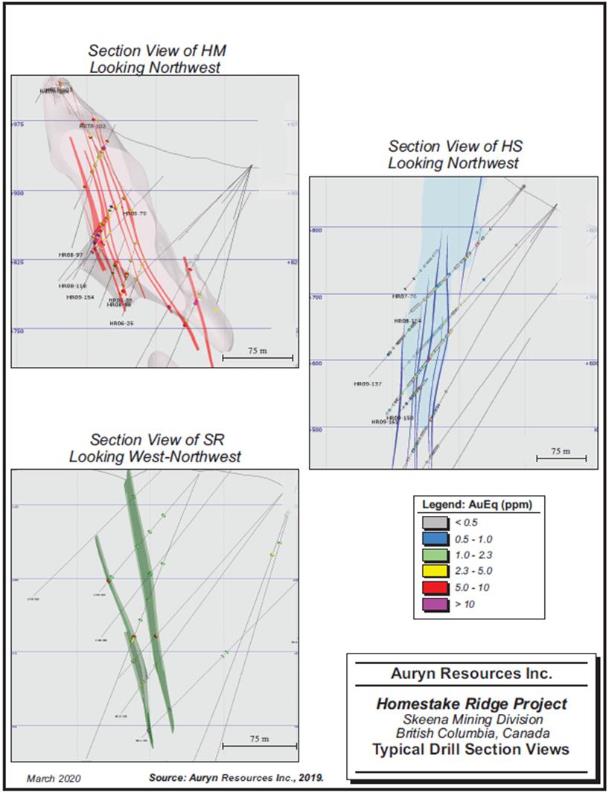

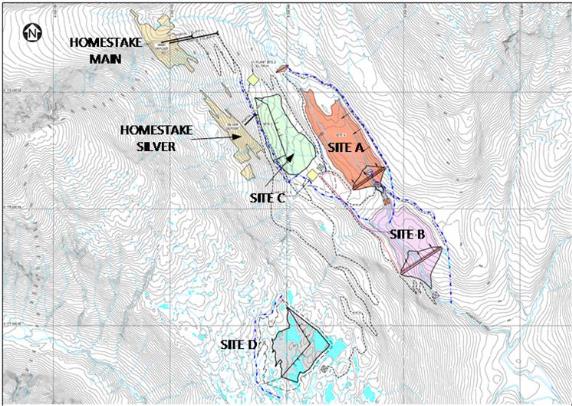

main zones of the Homestake Ridge deposit are the Homestake Main

(HM), Homestake Silver (HS), and South Reef (SR).

The

Homestake Main zone is the more copper-rich of the zones, with both

gold-rich and silver-rich variants and an apparent trend of

increasing copper grade with depth. Grades for gold typically

range from 0.1 g/t Au to 2 g/t Au with some intercepts measuring

into the hundreds of grams per tonne and averaged at 7.75 g/t Au.

Silver grades are generally in the 1.0 g/t Ag to 100 g/t Ag range

but can be as high as hundreds and even thousands of grams per

tonne. The average silver grade in the Homestake Main zone is

68.6 g/t Ag. Copper grades vary from parts per million to

several percent, with mean grades observed to increase

significantly with depth.

The

Homestake Silver zone, located approximately 0.5 km southeast of

Homestake Main, contains very little copper, and is relatively

higher in silver content. Silver grades at Homestake Silver

average 154 g/t Ag, approximately double that of the Homestake Main

zone (68.6 g/t Ag) and 26 times that of South Reef (5.8 g/t

Ag). Gold grades at Homestake Silver typically range up to

several g/t Au and averaged 3.5 g/t Au in the samples contained

within the interpreted zone boundaries. Copper content is

comparatively low, however, geochemically significant, and

generally measures between 10 ppm Cu and 500 ppm

Cu.

The

South Reef zone is comprised of two narrow sub-parallel tabular

bodies which strike at approximately 120° to 130° and dip

70°NE to 80°NE. To date, only twelve holes have

intersected significant mineralization, as such characterization of

the structure and grades is preliminary. The zones measure

one metre to three metres in thickness and have been traced for

approximately 300 m vertically and 400 m along strike.

Silver grades at SR average 5.8 g/t Ag in the vein samples.

This is offset by high gold values, which average 5.9 g/t

Au.

The

Homestake deposits are commonly vertically zoned from a base metal

poor Au-Ag-rich top to an Ag-rich base metal zone over a vertical

range of 250 m to 350 m. The silver-galena-sphalerite veins of the

Homestake Silver Zone exhibit many of these features.

Effective Project |

|

Page

1-2

Homestake

Ridge Project

NI43-101F1

Technical Report

1.4

Exploration Highlights

Since

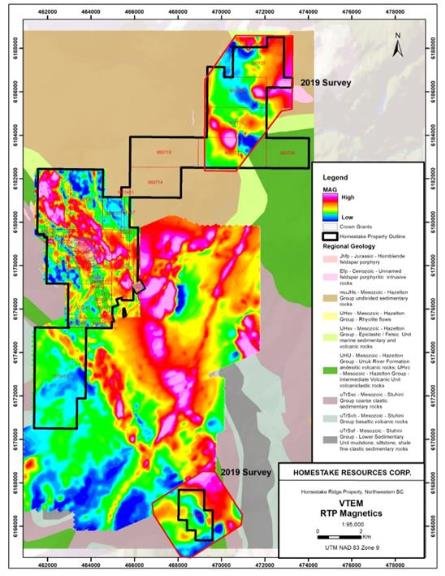

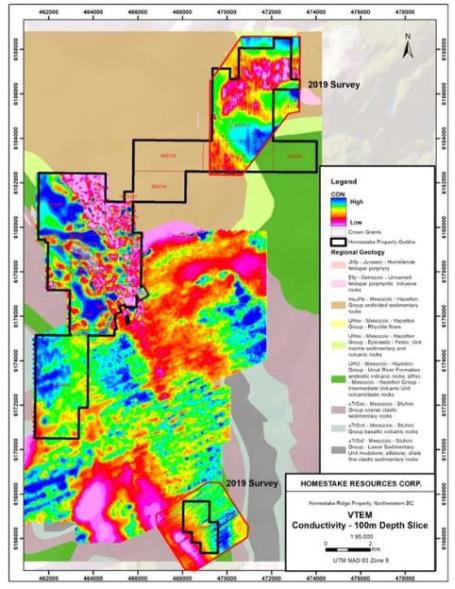

acquiring the Homestake Ridge Project in late 2016, Auryn has

completed extensive exploration across the Property to advance

additional targets to the drill ready stage. This work has

included geological mapping, rock and soil geochemical sampling,

portable X-ray fluorescence and shortwave infrared surveys,

geophysical (IP) surveying, the re-logging of historical drill

core, geochronological studies and airborne VTEM geophysical

surveys along with reprocessing of historic geophysical survey

data.

The

Homestake Ridge property hosts a number of other mineral

occurrences, however, none of these targets have NI43-101 complaint

Mineral Resources.

1.5

Mineral Resources

Resources were estimated considering a potential underground mining

scenario. At a cut-off grade of 2.0 g/t gold equivalent

(AuEq), Indicated Mineral Resources were estimated to total 0.736

million tonnes (Mt) at average grades of 7.02 g/t Au, 74.8 g/t Ag,

and 0.18 percent Cu. At the same cut-off grade, Inferred

Mineral Resources were estimated to total 5.545 Mt at average

grades of 4.58 g/t Au, 100.0 g/t Ag, and 0.13 percent Cu as shown

in Table 1-1.

Mineral Resources – Effective Date: December 31,

2019

Auryn Resources Inc. – Homestake Ridge Project

Classification And | | | | ||||||

| | | | | | | | ||

Indicated |

|

|

|

|

|

|

|

|

|

HM | | 7.02 | 74.8 | 0.18 | 0.077 | 165,993 | 1.8 | 2.87 | 1.25 |

Total | | | | | | | | | |

|

|

|

|

|

|

|

|

|

|

Inferred |

|

|

|

|

|

|

|

|

|

HM | | 6.33 | 35.9 | 0.35 | 0.107 | 355,553 | 2.0 | 13.32 | 4.14 |

HS | | 3.13 | 146.0 | 0.03 | 0.178 | 337,013 | 15.7 | 2.19 | 13.20 |

SR | | 8.68 | 4.9 | 0.04 | 0.001 | 124,153 | 0.1 | 0.36 | 0.00 |

Total | | | | | | | | | |

Notes:

1.

Canadian Institute of Mining, Metallurgy and Petroleum (CIM)

Definition Standards for Mineral Resources and Mineral Reserves

dated May 10, 2014 (CIM (2014) definitions), as incorporated by

reference in NI43-101, were followed for Mineral Resource

estimation.

2.

Mineral Resources are estimated at a cut-off grade of 2.0 g/t

AuEq.

Effective Project |

|

Page

1-3

Homestake

Ridge Project

NI43-101F1

Technical Report

3.

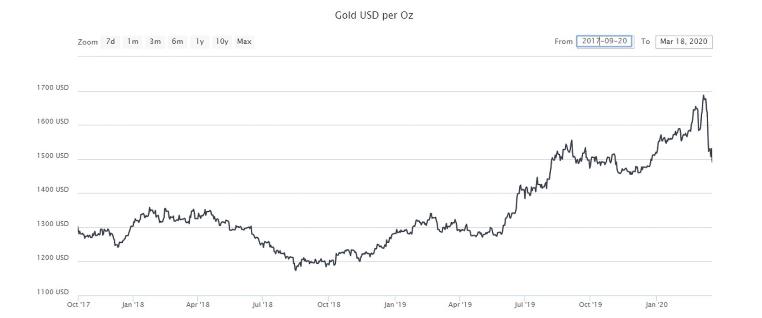

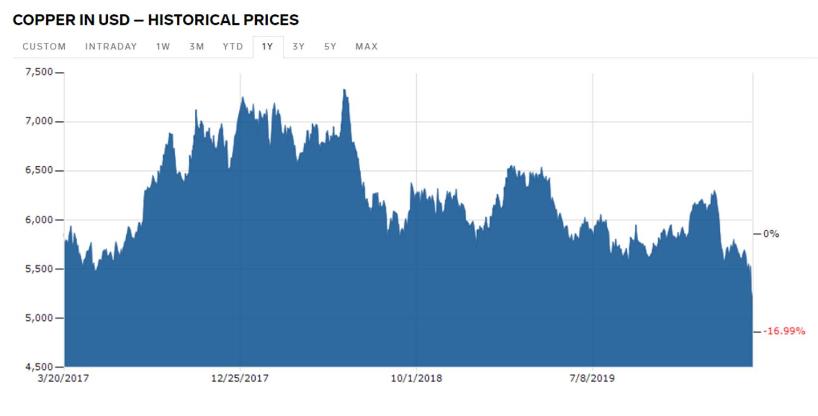

AuEq values were calculated using a long-term gold price of

US$1,300 per ounce, silver price at US$20 per ounce, and copper

price at US$2.50 per pound and a US$/C$ exchange rate of 1.2. The

AuEq calculation included provisions for metallurgical recoveries,

treatment charges, refining costs, and transportation.

4.

Bulk density ranges from 2.69 t/m3 to 3.03

t/m3

depending on the domain.

5.

Differences may occur in totals due to rounding.

6.

The Qualified Person responsible for this Mineral Resource Estimate

is Philip A. Geusebroek of Roscoe Postle Associates Inc. (RPA), now

part of SLR Consulting Ltd (SLR).

7.

The reader is cautioned that Mineral Resources that are not Mineral

Reserves do not have demonstrated economic viability.

8.

HM=Homestake Main Zone, HS= Homestake Silver Zone, and SR= South

Reef Zone.

The

Qualified Person is of the opinion that the practices and methods

used by Auryn to estimate Mineral Resources at the Project are in

accordance with the CIM (2014) definitions, and that the December

31, 2019 Mineral Resource estimate is reasonable and acceptable for

use in the Preliminary Economic Assessment (PEA).

1.6

Mineral Reserves

There

are no Mineral Reserves on the Homestake Ridge

Project.

1.7

Mining Operations

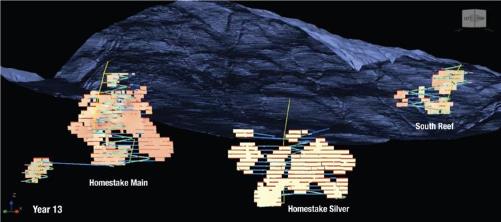

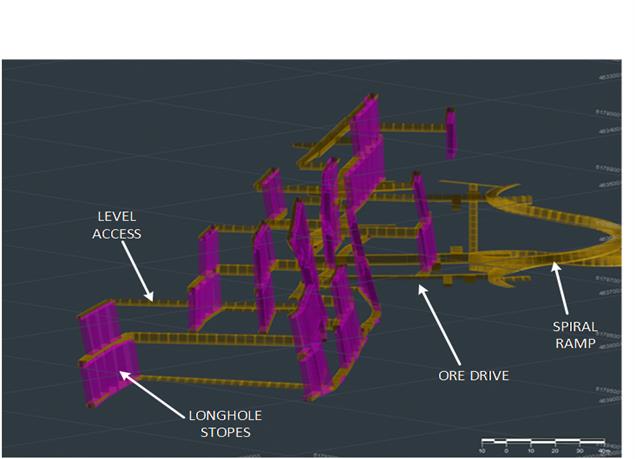

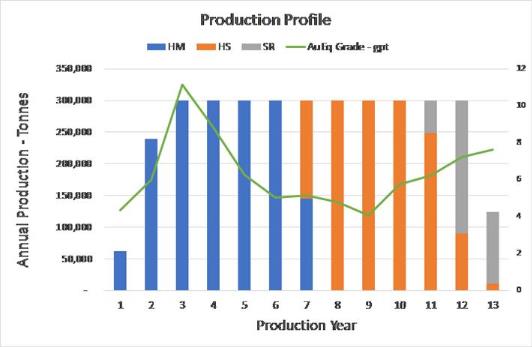

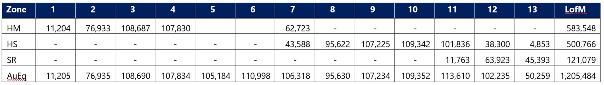

The PEA

mine plan and production schedule were generated with Deswik Stope

Optimizer software on the basis of the undated block model and

resource wireframes supplied by Auryn. The principal mining method

was longhole open stoping in a longitudinal direction, with a

minimum mining width of 2.5 m. A mining cutoff grade of 3.5

gpt gold-equivalent was used to define the stope

outlines.

The

resulting mine production schedule consists of 2.87 M stope tonnes

and 0.55 M mineralized development tonnes for a total of 3.42 Mt

grading 5.41 gpt Au, 84.31 gpt Ag, 0.13 percent Cu and 0.12 percent

Pb. The nominal mining rate is 900 tpd for an overall mine life of

13 years.

1.8

Processing

Processing

of Homestake Ridge mineralization will be complicated by the

difference in metal contents across the 3 principal deposits.

The Homestake Main mineralization is high in copper, low in lead,

and moderate in zinc. The Homestake Silver and South Reef

mineralization has low copper grades. Homestake Silver has

relatively low gold grades but high lead, zinc, and silver

grades. South Reef is essentially just gold with a minor

amount of copper.

Effective Project |

|

Page

1-4

Homestake

Ridge Project

NI43-101F1

Technical Report

The PEA

focuses on an optimal process strategy consisting of crushing and

grinding, followed by gravity recovery of a gold concentrate, then

selective flotation to produce base metal concentrates (one for

copper and one for lead/zinc) and finally regrinding and flotation

to produce a pyrite concentrate. Cyanide leaching of the

pyrite concentrate would be used to produce doré

bars.

1.9

Site Infrastructure

The

Homestake Ridge Project is a remote greenfields site with no

existing roads, power, water or camp infrastructure.

Development of the project will require:

■

Upgrading and

extending the current access road to allow the movement of freight,

consumable supplies and manpower

■

Installing local

hydro or diesel power, or connecting to the nearby BC Hydro

grid

■

Construction of a

person-camp to allow drive-in, drive-out (DIDO) manpower

rosters

■

Construction of a

900 tpd metallurgical plant

■

Construction of a

tailings dam and tailings storage facilities.

The

ancillary mine facilities include:

■

Core storage and

exploration offices

■

An assay

laboratory

■

Equipment

maintenance shops

■

Mine administration

and technical offices

■

Storage for diesel

fuel and lubricants

■

Explosives

magazine

■

Potable and fire

water.

Effective Project |

|

Page

1-5

Homestake

Ridge Project

NI43-101F1

Technical Report

1.10

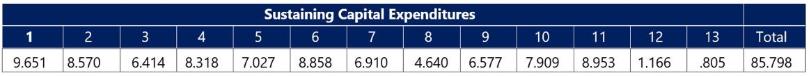

Capital Costs

The

pre-production capital cost has been estimated at US$88.4 million

(C$126.3 million) including all direct and indirect costs. The PEA

is based on contractor owned and operated equipment and manpower. A

contingency of 15 percent has been applied to all direct facility

costs.

Sustaining

costs have been estimated at US$85.8 million after a US$3.5 million

credit for the end-of-mine salvage.

1.11

Operating Costs

Operating

costs were developed from unit rate costs and benchmark costs for

projects of a similar size and scope. The all-in operating

costs have been estimated at US$89.40 per tonne

milled.

1.12

Financial Model

The

economic analysis was carried out using standard discounted

cashflow modelling techniques. The production and capital estimates

were estimated on an annual basis for the life of

mine.

Applicable

royalties were applied along with current Federal and Provincial

taxes and incorporated into the cashflow model. The economic

analysis was carried out on a 100 percent project basis. Given the

location and relatively uncomplicated nature of the project, the

Base Case uses a 5 percent discount factor in arriving at the

project Net Present Value (NPV). Standard payback calculation

methodology was also utilized.

project generates a Before-Tax cashflow of US$277 million (US$184

million After-Tax) over 13 years or roughly US$21 million in

free cashflow per year as shown in Table

1-2 below.

Financial Indicators

Qualified | | |

NPV | | |

NPV | | |

NPV | | |

IRR | | |

Payback | 34 | 36 |

As required by NI43-101, the author cautions the reader that the

PEA is preliminary in nature, that it includes Inferred mineral

resources that are considered too speculative geologically to have

the economic considerations applied to them that would enable them

to be categorized as mineral reserves, and there is no certainty

that the preliminary economic assessment will be

realized.

1.13

Qualified Persons Opinion

Based

on the analyses herein, it is the opinion of the Qualified Person

that the Homestake Ridge Project requires further study.

MineFill recommends the project be advanced to a Feasibility level

of evaluation.

Effective Project |

|

Page

1-6

2.

INTRODUCTION

2.1

The Issuer

This

Technical Report has been prepared for Auryn which is incorporated

in British Columbia, Canada. The Company has offices in Vancouver,

B.C., and is listed on the Toronto Stock Exchange and the

NYSE-American, with its common shares trading under the symbols

AUG.TO and AUG, respectively.

The

subject of this document is the Homestake Ridge Gold Project

located in the so-called Golden Triangle of north-central British

Columbia. The Company is the 100 percent owner and operator of the

Homestake Ridge Project which comprises 7,484.37 ha of mineral

claims and crown grants.

2.2

Terms of Reference

This

document presents the results of an updated Mineral Resource

Estimate and Preliminary Economic Assessment (PEA) of the Homestake

Ridge Project. The PEA was prepared in accordance with standard

industry practices and in accordance with CIM Definition Standards

on Mineral Resources and Reserves (dated May 10, 2014), and

Canadian Securities Administrators National Instrument 43-101

(Standards of Disclosure for Mineral Projects) dated June 30, 2011.

The effective date of this Technical Report is May 29,

2020.

2.3

Sources of Information

The

Homestake Ridge Project has been the subject of several prior

NI43-101 compliant Technical Reports. The most recent was completed

by Roscoe Postle Associates Inc. (RPA) dated September 29,

2017 (later amended on October 23, 2017). This document included an

updated mineral resource estimate.

Prior

Technical Reports on Homestake Ridge include:

■

A 2013 Technical

Report dated June 7, 2013 by Macdonald and Rennie for Homestake

Resource Corporation.

■

A 2011 Technical

Report dated May 20, 2011 by RPA for Bravo Gold Corp.

■

A 2010 Technical

Report dated June 28, 2010 by Scott Wilson RPA for Bravo Gold

Corp.

■

A 2007 Technical

Report dated April 11, 2007 and amended on June 3, 2008 by Folk and

Makepeace for Bravo Venture Group.

Effective Project |

|

Page

2-1

Bravo

Gold also completed a number of engineering studies on the site

including:

■

A January 24, 2012

geotechnical assessment of the proposed new road extension for the

Homestake Ridge Access Road by Golder Associates.

■

A February 27, 2012

preliminary geotechnical assessment of the proposed mine

infrastructure sites for the Homestake Ridge Project by Golder

Associates.

■

A Road Design

Package for the Homestake Ridge access road by AllNorth Consultants

dated March 20, 2009.

■

A Kitsault River

Road Review Inspection report by AllNorth Consultants dated

August 26, 2010.

■

A Homestake Ridge

Mainline Access Road Feasibility Study by AllNorth Consultants

dated March 3, 2012.

■

Conceptual mine

site layouts and run of river hydropower assessments by Knight

Piesold dated June 1, 2011.

■

A preliminary power

study supply assessment by Knight Piesold dated April 23,

2011.

■

A report on

integration of Hydroelectric power within the mine development

concepts by Knight Piesold dated June 1, 2011.

■

A plant site and

tailings storage facility alternatives assessment by Knight Piesold

dated May 19, 2011.

■

A conceptual cost

estimate for tailings disposal by Knight Piesold dated May 13,

2011.

■

An October 11, 2011

site inspection report by Knight Piesold.

■

A preliminary ore

sorting investigation and benchtop amenability test by Commodas

Ultrasort/Tomra Sorting Solutions dated June 14, 2012.

The

project library includes a number of other supporting documents,

drawings and historical data related to hydroelectric power in the

Kitsault region, at the adjacent Kitsault Lake, and at

Anyox.

Effective Project |

|

Page

2-2

2.4

Qualified Persons

Qualified Persons for this Technical Report are as listed in

Table 2-1 below.

Qualified Persons

| | | |

| MineFill | All Sections Section Section | |

| RPA | Sections Section | |

| RPA | Sections | |

| OneEighty | Section Section | |

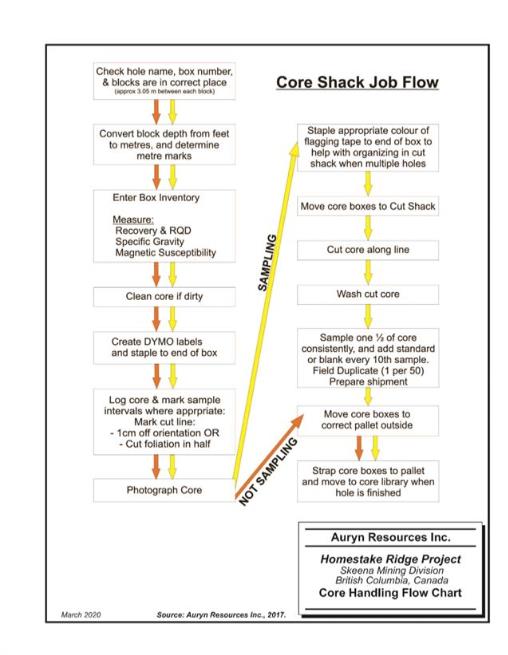

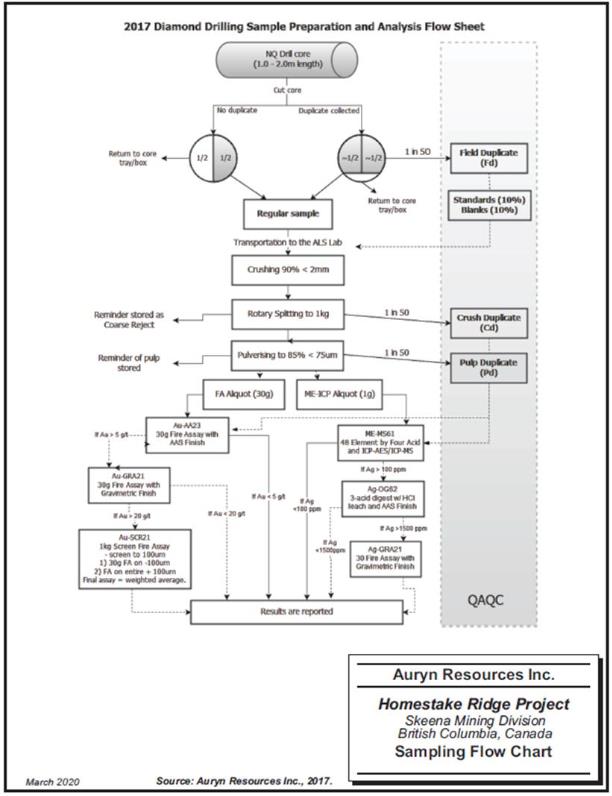

Paul Chamois, M.Sc. (A), P.Geo., Principal Geologist with RPA and

an independent QP, visited the Project from August 26 to 28, 2017.

During the visit, Mr. Chamois examined core from the on-going

drilling program, confirmed the local geological setting, reviewed

the core handling and data collection methodologies, and

investigated factors that may affect the Project. Due to the

advanced nature of the Project, no independent samples were taken

during the visit.

In the QP’s opinion, the limited work carried out during 2018

and 2019 is not material to the project. None of the post-2017

exploration work was utilized in the resource estimation outlined

in Section 14, nor in the Preliminary Economic Assessment. The

QP’s have reviewed Auryn’s regulatory filings,

assessment reports, news releases and databases to verify that no

material work was completed on the property post 2017.

None of the other Qualified Persons have visited the project

site.

Effective Project |

|

Page

2-3

2.6

Terms and Definitions

Units

of measurement used in this report conform to the metric

system.

a | annum | L | litre |

A | ampere | lb | pound |

bbl | barrels | L/s | litres |

btu | British | m | metre |

°C | degree | M | mega |

C$ | Canadian | m2 | square |

cal | calorie | m3 | cubic |

cfm | cubic |

| micron |

cm | centimetre | MASL | metres |

cm2 | square | g | microgram |

d | day | m3/h | cubic |

dia | diameter | mi | mile |

dmt | dry | min | minute |

dwt | dead-weight | m | micrometre |

°F | degree | mm | millimetre |

ft | foot | mo | month |

ft2 | square | mph | miles |

ft3 | cubic | Mtpa | Million |

ft/s | foot | Mtpd | Million |

g | gram | MVA | megavolt-amperes |

G | giga | MW | megawatt |

Gal | Imperial | MWh | megawatt-hour |

g/L | gram | oz | Troy |

Gpm | Imperial | oz/st, | ounce |

| gpt | gram | ppb | part |

gr/ft3 | grain | ppm | part |

gr/m3 | grain | psia | pound |

ha | hectare | psig | pound |

hp | horsepower | RL | relative |

hr | hour | s | second |

Hz | hertz | t | tonne |

in2 | square | tpa | tonnes |

J | joule | tpd | tonnes |

k | kilo | US$ | United |

kcal | kilocalorie | USg | United |

kg | kilogram | USgpm | US |

km | kilometre | V | volt |

km2 | square | W | watt |

km/h | kilometre | wmt | wet |

kPa | kilopascal | wt% | weight |

kVA | kilovolt-amperes | yd3 | cubic |

kW | kilowatt | yr | year |

kWh | kilowatt-hour |

|

|

Effective Project |

|

Page

2-4

3.

RELIANCE ON OTHER EXPERTS

The

authors are not qualified to provide an opinion or comment on

issues related to legal agreements, royalties, permitting matters,

and taxes.

The

authors of this Technical Report have relied on non-QPs for Section

4.3, Mineral Tenure.

For the

purpose of this report, the Qualified Person’s have relied on

ownership information provided by Auryn and Broughton Law

Corporation (Broughton Law), regarding title to the Homestake Ridge

Project. Broughton Law provided a legal review and opinion dated

September 7, 2016. This information was used in Sections 1 and 4 of

this report. The Qualified Persons have not researched property

title or mineral rights for the Homestake Ridge Project and

expresses no opinion as to the ownership status of the

property.

Effective Project |

|

Page

3-1

4.

PROPERTY DESCRIPTION AND LOCATION

4.1

Location

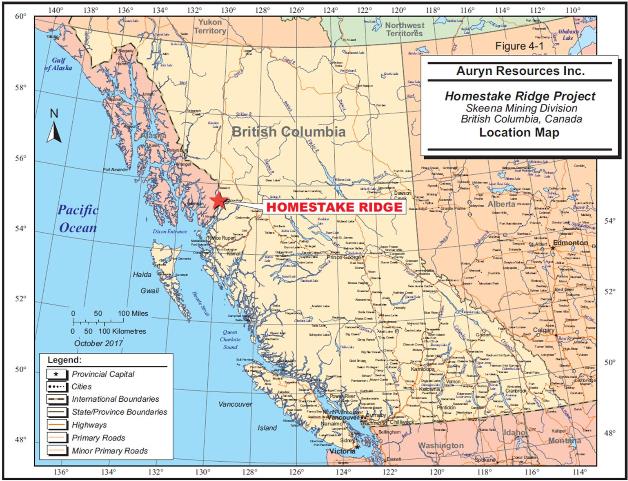

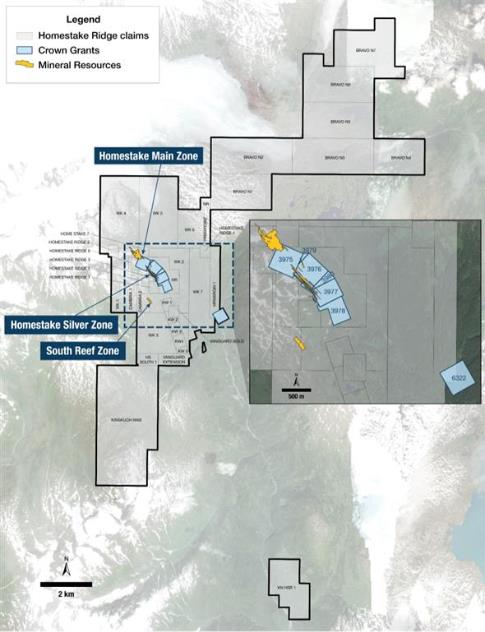

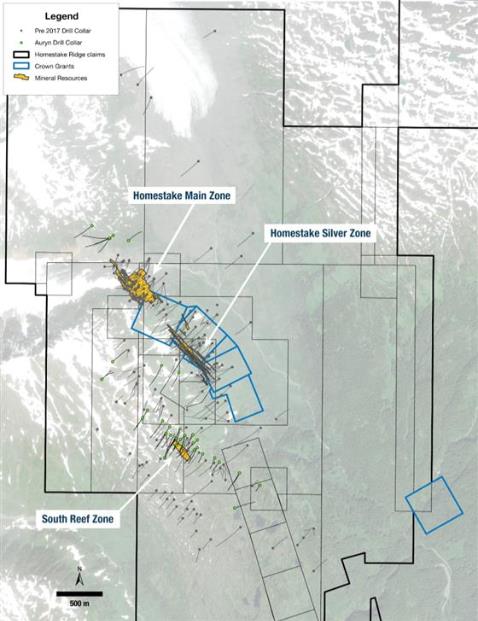

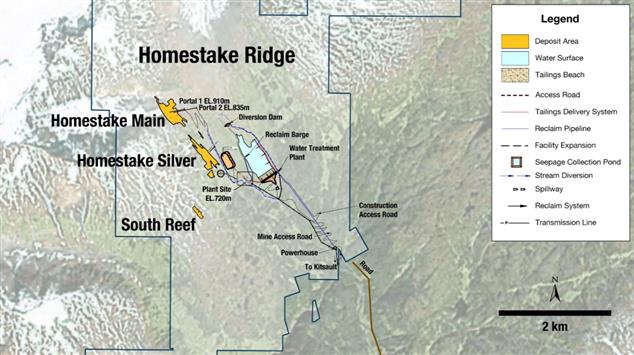

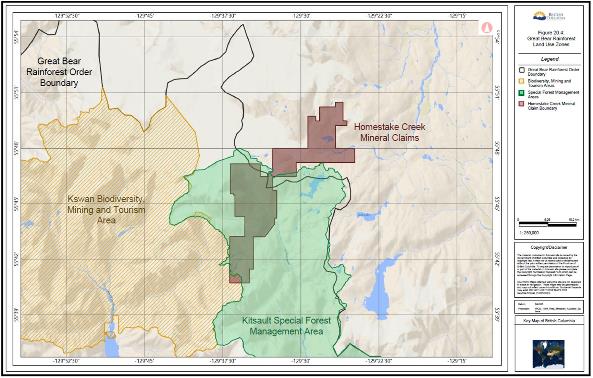

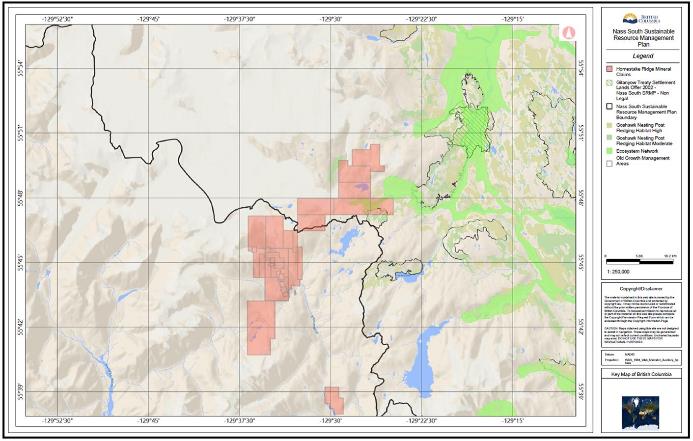

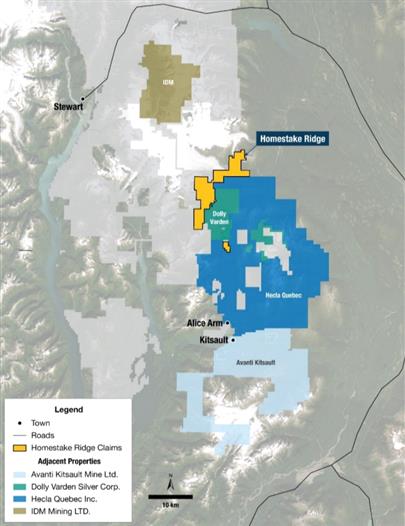

Homestake Ridge Project covers 7,484.37 hectares and is located 32

km southeast of Stewart, BC, and approximately 32 km

north-northwest of the tidewater communities of Alice Arm and

Kitsault, BC (Figure 4.1). The

property is located on 1:50,000 scale NTS map 102/P13.

The

four claim blocks comprising the Project are located within a

rectangular area extending for a distance of approximately 23 km in

a north-south direction and approximately 13 km in an east-west

direction. The claim block hosting the known Mineral Resources is

centered on approximately 55° 45′ 12.6″ N latitude and

129° 34′ 39.8″ W longitude on Terrain Resource Integrated

Management (TRIM) maps 103P072 and 103P073 and lies within Zone 9

of the UTM projection using the NAD’83 datum.

Project Location Map

Effective Project |

|

Page

4-1

4.2

Project Ownership

On June

14, 2016, Auryn announced that it had entered into a binding letter

agreement with Homestake Resource Corporation (Homestake) whereby

it would acquire Homestake under a plan of arrangement (the

Arrangement). In consideration for 100 percent of Homestake’s

issued and outstanding shares, Auryn would issue approximately 3.3

million shares to Homestake shareholders. During the Arrangement

process, Auryn also agreed to provide Homestake with a demand loan

of up to C$150,000 on an interest free, unsecured basis. On

September 8, 2016, Auryn announced that it had completed the

Arrangement and that Homestake had become a wholly owned subsidiary

of Auryn.

4.3

Mineral Tenure

Project comprises four non-contiguous blocks consisting of seven

crown granted claims covering 96.712 ha and 37 mineral claims

covering 7,484.37 ha (Figure 4.2).

Table 4-1 lists the mineral claims

along with the relevant individual tenure information including

tenure number and name, issue and expiry dates, title type, and

area. Table 4-2 lists the crown granted

claims.

The

crown grants include surface rights whereas the mineral claims do

not.

There

are no holding costs or work expenditure requirements for the crown

grants other than roughly C$300 per year in property

taxes.

The

mineral claims are subject to minimum work requirements

of:

■

C$5 per hectare for

anniversary years 1 and 2;

■

C$10 per hectare

for anniversary years 3 and 4;

■

C$15 per hectare

for anniversary years 5 and 6; and

■

C$20 per hectare

for subsequent anniversary years.

in 2019, on the mineral claims shown in Table 4-1, amounted to C$860,000.

Effective Project |

|

Page

4-2

Homestake Ridge

Project

NI43-101F1

Technical Report

Homestake Mineral Claims

Title | Claim | Owner | Client | Issue | Good to | Area | Protected | Tenure Sub Type | Title Type | Title Type | Tenure Type |

950714 | BRAVO N1 | HOMESTAKE RESOURCE | 202433 | February 19, | June 13, 2029 | 327.49 | N | CLAIM | Mineral Cell Title | MCX | M |

950719 | BRAVO N2 | HOMESTAKE RESOURCE | 202433 | February 19, | June 13, 2029 | 436.51 | N | CLAIM | Mineral Cell Title | MCX | M |

950722 | BRAVO N3 | HOMESTAKE RESOURCE | 202433 | February 19, | June 13, 2029 | 436.50 | N | CLAIM | Mineral Cell Title | MCX | M |

950724 | BRAVO N4 | HOMESTAKE RESOURCE | 202433 | February 19, | June 13, 2029 | 272.81 | N | CLAIM | Mineral Cell Title | MCX | M |

950725 | BRAVO N5 | HOMESTAKE RESOURCE | 202433 | February 19, | June 13, 2029 | 381.82 | N | CLAIM | Mineral Cell Title | MCX | M |

950726 | BRAVO N6 | HOMESTAKE RESOURCE | 202433 | February 19, | June 13, 2029 | 418.04 | N | CLAIM | Mineral Cell Title | MCX | M |

950727 | BRAVO N7 | HOMESTAKE RESOURCE | 202433 | February 19, | June 13, 2029 | 417.96 | N | CLAIM | Mineral Cell Title | MCX | M |

1011645 | KN HSR 1 | HOMESTAKE RESOURCE | 202433 | August 1, 2012 | March 9, 2023 | 273.86 | N | CLAIM | Mineral Cell Title | MCX | M |

1061421 | NR | HOMESTAKE RESOURCE | 202433 | August 25, 2006 | August 30, 2029 | 18.20 | N | CLAIM | Mineral Cell Title | MCX | M |

251427 | CAMBRIA 1 | HOMESTAKE RESOURCE | 202433 | May 6, 1986 | December 17, | 100.00 | N | CLAIM | Four Post Claim | MC4 | M |

251428 | CAMBRIA 2 | HOMESTAKE RESOURCE | 202433 | May 6, 1986 | December 17, | 75.00 | N | CLAIM | Four Post Claim | MC4 | M |

377241 | WK 1 | HOMESTAKE RESOURCE | 202433 | May 23, 2000 | December 17, | 250.00 | N | CLAIM | Four Post Claim | MC4 | M |

377242 | WK 2 | HOMESTAKE RESOURCE | 202433 | May 23, 2000 | December 17, | 500.00 | N | CLAIM | Four Post Claim | MC4 | M |

377243 | WK 3 | HOMESTAKE RESOURCE | 202433 | May 23, 2000 | December 17, | 400.00 | N | CLAIM | Four Post Claim | MC4 | M |

380949 | WK 4 | HOMESTAKE RESOURCE | 202433 | September 20, | December 17, | 450.00 | N | CLAIM | Four Post Claim | MC4 | M |

380950 | WK 5 | HOMESTAKE RESOURCE | 202433 | September 20, | December 17, | 450.00 | N | CLAIM | Four Post Claim | MC4 | M |

380951 | KW 1 | HOMESTAKE RESOURCE | 202433 | September 20, | December 17, | 25.00 | N | CLAIM | Two Post Claim | MC2 | M |

380952 | KW 2 | HOMESTAKE RESOURCE | 202433 | September 20, | December 17, | 25.00 | N | CLAIM | Two Post Claim | MC2 | M |

380953 | KW 3 | HOMESTAKE RESOURCE | 202433 | September 20, | December 17, | 25.00 | N | CLAIM | Two Post Claim | MC2 | M |

383016 | KW 5 | HOMESTAKE RESOURCE | 202433 | November 28, | December 17, | 25.00 | N | CLAIM | Two Post Claim | MC2 | M |

383017 | KW4 | HOMESTAKE RESOURCE | 202433 | November 28, | December 17, | 25.00 | N | CLAIM | Two Post Claim | MC2 | M |

383037 | WK 6 | HOMESTAKE RESOURCE | 202433 | November 28, | December 17, | 150.00 | N | CLAIM | Four Post Claim | MC4 | M |

383038 | WK 7 | HOMESTAKE RESOURCE | 202433 | November 28, | December 17, | 400.00 | N | CLAIM | Four Post Claim | MC4 | M |

537435 | HR | HOMESTAKE RESOURCE | 202433 | July 20, 2006 | December 17, | 127.45 | N | CLAIM | Mineral Cell Title | MCX | M |

537436 | HRMARGIN 1 | HOMESTAKE RESOURCE | 202433 | July 20, 2006 | December 17, | 109.25 | N | CLAIM | Mineral Cell Title | MCX | M |

537437 | HRMARGIN2 | HOMESTAKE RESOURCE | 202433 | July 20, 2006 | December 17, | 54.60 | N | CLAIM | Mineral Cell Title | MCX | M |

538791 | HOMESTAKE RIDGE | HOMESTAKE RESOURCE | 202433 | August 5, 2006 | December 17, | 18.21 | N | CLAIM | Mineral Cell Title | MCX | M |

540533 | HOMESTAKE RIDGE | HOMESTAKE RESOURCE | 202433 | September 6, | December 17, | 18.20 | N | CLAIM | Mineral Cell Title | MCX | M |

540540 | HOMESTAKE RIDGE | HOMESTAKE RESOURCE | 202433 | September 6, | December 17, | 18.21 | N | CLAIM | Mineral Cell Title | MCX | M |

545945 | HOMESTAKE RIDGE | HOMESTAKE RESOURCE | 202433 | November 27, | December 17, | 18.20 | N | CLAIM | Mineral Cell Title | MCX | M |

565708 | HOMESTAKE RIDGE | HOMESTAKE RESOURCE | 202433 | September 7, | December 17, | 36.42 | N | CLAIM | Mineral Cell Title | MCX | M |

565709 | HOMESTAKE RIDGE | HOMESTAKE RESOURCE | 202433 | September 7, | December 17, | 18.21 | N | CLAIM | Mineral Cell Title | MCX | M |

565710 | HOME STAKE 7 | HOMESTAKE RESOURCE | 202433 | September 7, | December 17, | 18.20 | N | CLAIM | Mineral Cell Title | MCX | M |

598667 | VANGUARD GOLD | HOMESTAKE RESOURCE | 202433 | February 3, | December 17, | 18.21 | N | CLAIM | Mineral Cell Title | MCX | M |

598668 | VANGUARD | HOMESTAKE RESOURCE | 202433 | February 3, | December 17, | 54.66 | N | CLAIM | Mineral Cell Title | MCX | M |

1015450 | KINSKUCH NW2 | HOMESTAKE RESOURCE | 202433 | December 22, | December 17, | 1039.18 | N | CLAIM | Mineral Cell Title | MCX | M |

1015588 | HS SOUTH 1 | HOMESTAKE RESOURCE | 202433 | December 31, | December 17, | 36.44 | N | CLAIM | Mineral Cell Title | MCX | M |

|

| | |

| | |

|

|

|

|

|

Source:

Auryn, 2019

Effective Project |

|

Page

4-3

Homestake Ridge

Project

NI43-101F1

Technical Report

Crown Grants

District | Claim | CTGVRNNGPR | PRCLTP | SRVRGNRLPL | STTFPRCLSR | Area | CRWNGRNTNO | Mining | Lot |

3975 | HOMESTAKE | Mineral Tenure | Primary | 37TR7 CASSIAR | Active | 20.902 | 4004/511 | SKEENA | CROWN GRANTED |

3978 | HOMESTAKE NO. 3 | Mineral Tenure | Primary | 37TR7 CASSIAR | Active | 13.962 | 4007/311 | SKEENA | CROWN GRANTED |

3977 | HOMESTAKE NO. 2 | Mineral Tenure | Primary | 37TR7 CASSIAR | Active | 15.042 | 4006/511 | SKEENA | CROWN GRANTED |

3976 | HOMESTAKE NO. 1 | Mineral Tenure | Primary | 37TR7 CASSIAR | Active | 20.283 | 4005/511 | SKEENA | CROWN GRANTED |

3980 | HOMESTAKE NO. 1 | Mineral Tenure | Primary | 37TR7 CASSIAR | Active | 4.702 | 5622/527 | SKEENA | CROWN GRANTED |

3979 | HOMESTAKE | Mineral Tenure | Primary | 37TR7 CASSIAR | Active | 0.919 | 5621/527 | SKEENA | CROWN GRANTED |

6322 | MILLSITE | Land Act | Primary | 1TR8 CASSIAR | Active | 20.902 | 8826/859 | SKEENA | CROWN GRANTED |

|

| | |

| | |

|

|

|

Source:

Auryn, 2019

Effective Project |

|

Page

4-4

Homestake

Ridge Project

NI43-101F1

Technical Report

Source:

Auryn

Claims

Effective Project |

|

Page

4-5

Homestake

Ridge Project

NI43-101F1

Technical Report

4.4

Royalties and Encumbrances

Homestake

earned a 100 percent interest in 14 Homestake Ridge mineral claims

through its option with Teck Cominco Limited, now Teck Resources

(Teck). Teck failed to exercise its back-in rights in 2008 but

retained a 2 percent net smelter return (NSR) royalty, 1 percent of

which could be purchased at a future date for C$1.0 million. On May

16, 2016 Homestake announced that it had closed an agreement with

Teck to purchase the 2 percent royalty and ancillary rights for

C$100,000, effectively extinguishing this royalty.

The

Coombes Claims (including Cambria 1, Cambria 2, KW1, KW2, KW3, KW4,

KW5, WK1, WK3, WK4, WK6 and WK7) are subject to a 2 percent NSR

royalty by virtue of an option agreement dated July 5, 2000. The

royalty includes a purchase right in favour of Homestake for

C$1,000,000.

The

crown grants (including DL 3975, DL 3976, DL 3977, DL 3978, DL

3979, DL 3980, and DL 6322) are subject to a 2 percent NSR royalty

which includes an annual advanced minimum royalty of C$50,000 in

favour of Alice Sullivan and Mildred Keller.

of the claims subject to royalty is attached in Figure 4.3.

4.5

Property Agreements

The

authors are not aware of any other underlying agreements,

obligations or back-in rights related to the Property other than

those disclosed herein.

4.6

Permitting Considerations

Auryn

Resources currently holds a Mineral and Coal Activities and Reclamation

Permit (Permit No. MX-1-603) that includes the

following approved work:

■

Camp with 1.0 ha of

disturbance

■

Geophysical surveys

of 50 line km

■

Surface drilling at

500 drill sites

■

2 km of exploration

trails.

The

above permit is secured with a C$68,000 reclamation bond and all

work must be complete by March 23, 2023.

The

Company has also been granted a Free Use Permit (No.

MX-1-603:2018-2023) for the harvesting of Crown timber on the Crown

granted lands.

Effective Project |

|

Page

4-6

Homestake

Ridge Project

NI43-101F1

Technical Report

Source:

Auryn

Royalty

Effective Project |

|

Page

4-7

Homestake

Ridge Project

NI43-101F1

Technical Report

4.7

Environmental Considerations

The

Homestake Ridge Property is a greenfield site with no known

pre-existing development or environmental liabilities.

4.8

Social License Considerations

Auryn

does not have any Community or Social Agreements in

place.

4.9

Comments on Section 4

The

authors are not aware of any significant factors or risks that may

affect access to the project site, or the right and ability to

perform work on the property.

Effective Project |

|

Page

4-8

Homestake

Ridge Project

NI43-101F1

Technical Report

5.

ACCESSIBILITY, CLIMATE, LOCAL RESOURCES,INFRASTRUCTURE, AND

PHYSIOGRAPHY

5.1

Site Access

The

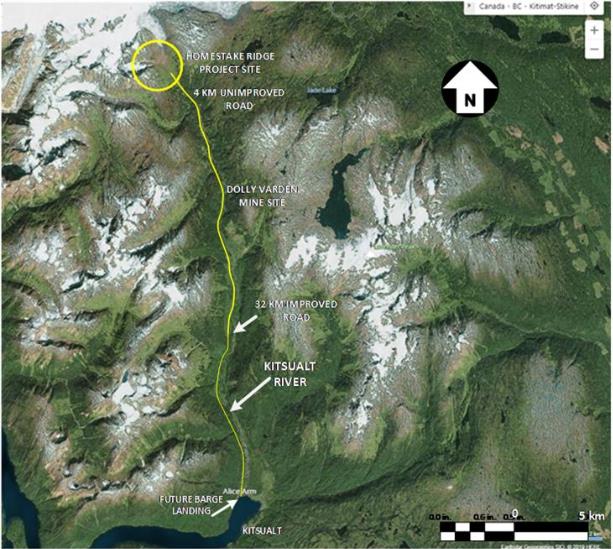

Homestake Ridge Project is located 32 km southeast of Stewart, BC,

at the southern extent of the Cambria ice field. Access to the

Project from the town of Kitsault is by boat/barge to the community

of Alice Arm. From there, an upgraded tractor trail follows an old

railway bed for a distance of 32 km into the area of the past

producing Dolly Varden silver mine, approximately four kilometres

from the southern boundary of the Project. From there, overgrown

mule trails lead to the historic workings of the Vanguard and

Homestake areas of the Project (Figure 5.1).

In the absence of upgraded road access, the site is only accessible

by helicopter as shown in Figure

5.1. Helicopters are

available for charter from either Prince Rupert, Terrace, or

Stewart.

5.2

Climate

Climate in the area is transitional, with moderately wet to dry,

warm summers, and cool, wet winters (Ministry of Forests, 1993)

driven by moist Pacific air that brings intense precipitation to

the windward slopes and adjacent mountains, and by the cold Arctic

air to pass down the Portland Canal through onto the Dixon Entrance

(Demarchi, 2011). The area is classified as Oceanic or Marine West

Coast and is characterized by moderately cool summers and mild

winters with a narrower annual range of temperatures compared to

sites of similar latitude. Climate data derived from historic

monitoring stations at Alice Arm, and more recent long-ranging

monitoring at Stewart and Nass Camp Table

5-1) indicates that

temperatures range from an average low of – 6°C in

January to an average high of 15°C in July. The mean

temperature for the year is 5°C.

area receives between 984 – 1,838 mm of precipitation each

year (expressed in mm of water Table

5-1). Rainfall peaks in October with 150 mm. Snowfall is

highest in December and January when accumulations are 287 cm and

86 cm, respectively, at Nass Camp (Government of Canada, 2019).

Precipitation and heavy fog often impact on airborne access to the

Project (RPA, 2017).

The

property is reported to be covered in snow from late September to

late June (Bryson, 2007). The ground is generally frozen throughout

the winter and breakup occurs between early March and late May

(Ministry of Forests, 1993). Rainfall / snowfall distribution

ranges from 45 – 55 percent (Knight Piesold,

2011).

Effective Project |

|

Page

5-1

Homestake

Ridge Project

NI43-101F1

Technical Report

Source:

MineFill Services, Inc.

Effective Project |

|

Page

5-2

Homestake

Ridge Project

NI43-101F1

Technical Report

Climatic Data

| | | |

Meteorological | | | |

Latitude | | | |

Longitude | | | |

Elevation | | | |

Distance | | | |

Period | | | |

Mean | | | |

Mean | | | |

Extreme | | | |

Extreme | | | |

Average | | | |

Average | | | |

Average | | | |

5.3

Local Resources and Infrastructure

The

nearest communities to the Homestake project site include the towns

of Kitsault and Alice Arm, roughly 35 km distant. Both of these

towns are essentially ghost towns with few residents and no

services.

Labour

and supplies for the project can be brought in from the community

of Terrace, which lies 185 km to the south, along Highway 113.

Terrace has a population of 11,643 (2016 census) and hosts a wide

range of supplies, services, and trained labour. Terrace is

serviced by three air carriers with daily scheduled

flights.

Stewart

with a population of 400 (2016 census) is located 240 km, by road,

from Kitsault. Stewart is well serviced, has trained labour with

mining expertise, and hosts a deep-sea port that has been used for

shipping ore and concentrate from other mines. Concentrates and

bulk supplies, such fuel, could be barged between Alice Arm and

Stewart, an ocean distance of some 225 km.

Kitwanga,

180 km by road from Kitsault, lies on the Canadian National Railway

mainline and Trans-Canada Highway 16. Like Stewart, Kitwanga has

served as a shipping centre for mineral ores and concentrates.

Mining is supported in the local communities and, historically,

companies have been able to form productive joint venture

partnerships with local First Nations.

Effective Project |

|

Page

5-3

Homestake

Ridge Project

NI43-101F1

Technical Report

5.4

Physiography

5.4.1

Terrain

The

project area is situated in steep terrain on the geologic boundary

between the Coastal Belt and the Intermontane Belt, within an

elevation range of 500 to 1100 masl (Knight Piesold, 2011). The

project area lies at the transition from the Southern Boundary

Ranges to the Meziadin Mountains ecosections (iMapBC, 2020). The

Southern Boundary Ranges ecosection is an area of wet rugged

mountains that are capped with glaciers, small icefields and

exposed granitic and metamorphic bedrock. This area was heavily

impacted by large sheets of ice that originated along the crest of

the mountains and the area south of the Homestake Ridge Project is

bisected by the Portland Canal (Demarchi, 2011). The Meziadin

Mountains comprise the leeward side of the main Boundary Ranges and

extend west of the low Nass Basin. Ice that formed in the Boundary

Ranges moved east into the Nass Basin, coalescing with ice moving

south from the adjacent Skeena Mountains, then the entire ice mass

moved down out the Nass Valley to the Dixon Entrance or south

through Cranberry Upland Ecosection to the Skeena River valley. The

mountain summits still have small icefields or glaciers (Demarchi,

2011).

The

area is characterized by steep headwater streams and gullies that

drain the mountainsides, carrying water, sediment and organic

materials to the fans and floodplains that line valley bottoms.

Lakes head some valleys. Small wetlands are common on floodplains,

but extensive wetlands are uncommon (Price and McLennan,

2001).

5.4.2

Vegetation

The

Project overlays a south-southeast trending ridge at the headwaters

of the Kitsault River and the lower portions of the Kitsault and

Little Kitsault Glaciers. The eastern and southern portions of the

property at lower elevations is subalpine forest, comprised of

subalpine fir, western hemlock, Roche spruce, and mountain hemlock.

East of this ridge, the subalpine forest is broken up by a large

slide area that is covered by slide alder, grass, and lichen.

Alpine areas are extensive at higher elevations, but are mainly

barren rock or ice covered. Many large remnant icefields and

glaciers remain on the summits north-west of the project area

(Demarchi, 2011). The upper slopes are populated by alpine grass,

moss, and lichen with intermittent patches of dwarf alpine spruce

(Knight and Macdonald, 2010).

Regionally,

the vegetation in the area is driven by the transitional nature of

the climate on the leeward side of the Coast Mountains, and

consequently combines elements of both coastal and interior flora

(BC Ministry of Forests, 1993). In the valley bottoms, in the

subalpine area, the understory vegetation includes a wide variety

of shrub and herbaceous species, including salmonberry, bunchberry,

various currants, five-leaf bramble, common snowberry, vine maple,

sword fern, twinflower, deer fern, western trillium and others

(Wright and Ebnet, nd). In the lower slopes of Portland Canal, the

forests are either very wet, such as coastal western hemlock or,

cold and wet, such as the subalpine mountain hemlock forests that

occur on all the middle elevation slopes (Demarchi,

2011).

Effective Project |

|

Page5-4

Homestake

Ridge Project

NI43-101F1

Technical Report

There

are no federally or provincially identified plant species at risk

in the project area (BC Conservation Data Centre, 2020). The

nearest observed plant species at risk is Polystichum setigerum

(Alaska holly fern), observed in 1975 in lower Kitsault River

approximately 2.5 km upstream from Alice Arm, classified as being

of “special concern” (BC Conservation Data Centre,

2020).

5.5

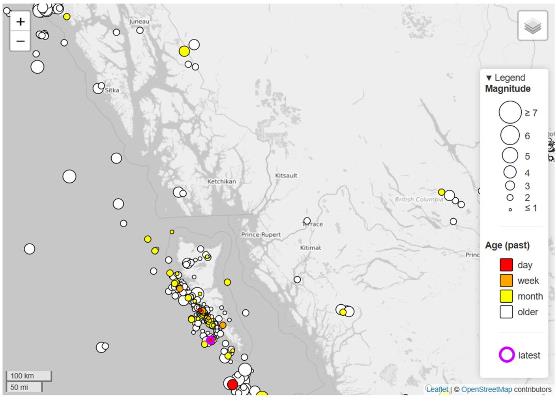

Seismicity

town of Stewart is located in a zone of low to moderate seismicity

with a peak ground acceleration of 0.031g for events with a 10

percent exceedance in 50 years (e.g. one in 1000-year event). As

can be seen in Figure 5.2 earthquake

frequency map, the main source of seismic risk is from the Cascadia

subduction zone, located 200 km from the Project site, off the

coast of British Columbia.

Source:

Natural Resources Canada

for Events in the Past 50 Years

Effective Project |

|

Page

5-5

Homestake

Ridge Project

NI43-101F1

Technical Report

5.6

Comments on Section 5

The

Homestake Ridge Project is a remote greenfields site with no

existing roads, power, water or camp infrastructure. Development of

the project will require:

■

Upgrading and

extending the current access road to allow the movement of freight,

consumable supplies and manpower

■

Installing local

hydro or diesel power, or connecting to the nearby BC Hydro

grid

■

Construction of a

person-camp to allow drive-in, drive-out (DIDO) manpower

rosters

■

Development of

local water resources for potable and non-potable water

consumption.

In the

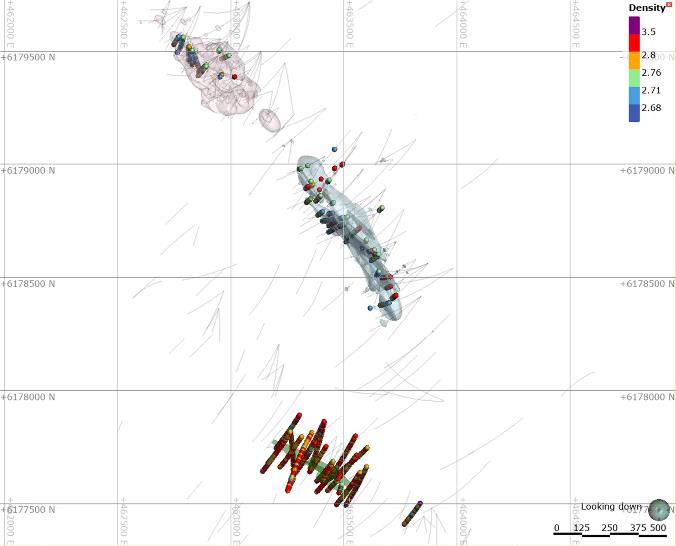

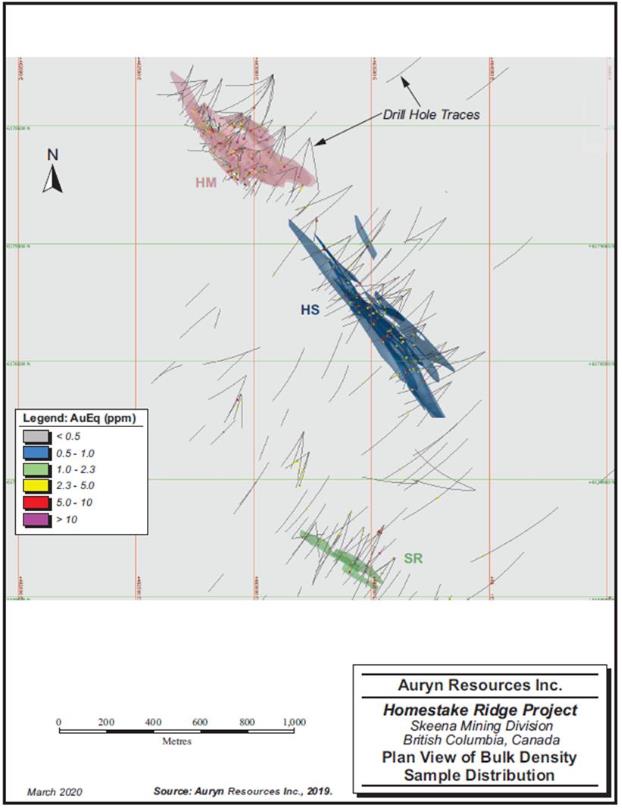

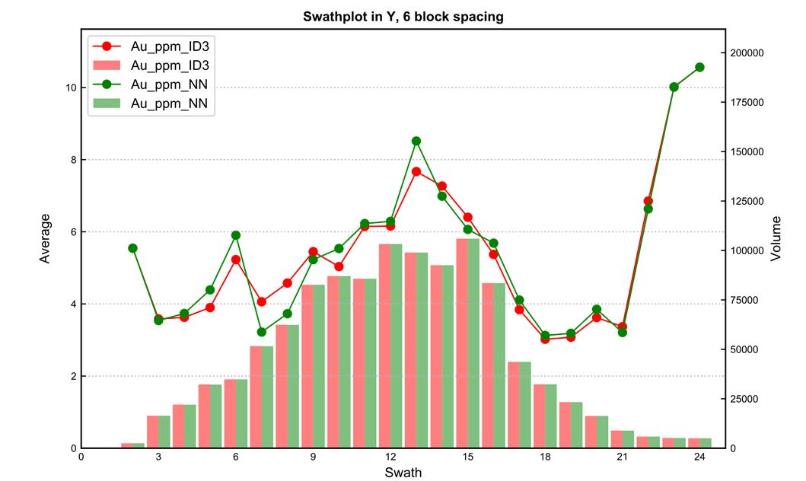

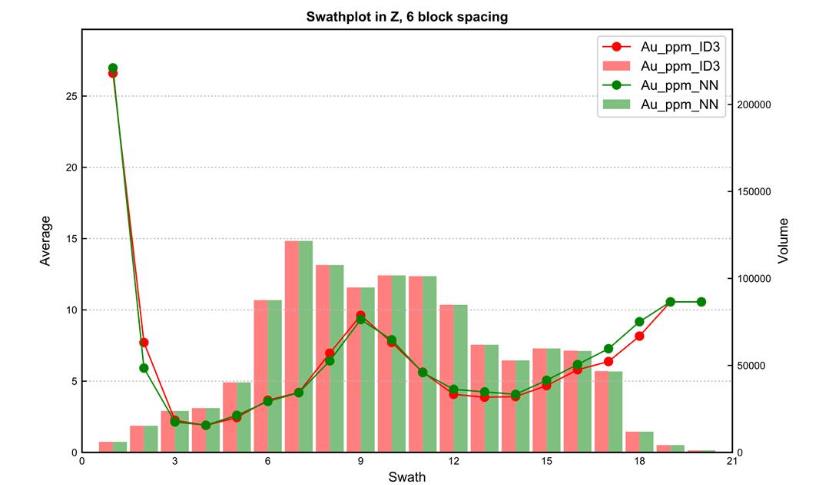

opinion of the Qualified Persons, the Homestake Ridge Project site